The Papa-Terra field in the Campos basin in Brazil is identified as having an oil interval of 14.6°API in turbidite sandstones. Because of the high-viscosity oil and low-API grade, innovative solutions and technological advances were incorporated into the project. The development uses an integrated production system consisting of a floating production, storage, and offloading (FPSO) vehicle connected to a tension-leg wellhead platform (TLWP) and dry completion wells. This allows the production of ultraheavy oil in deep water and enables rapid intervention for maintenance of electric submersible pumps (ESP).

Introduction

Because of the properties of the oil from the Papa-Terra field (high viscosity at low temperatures and low gas/oil ratio), the whole production development concept of the field was driven by artificial lift and flow-assurance requirements.

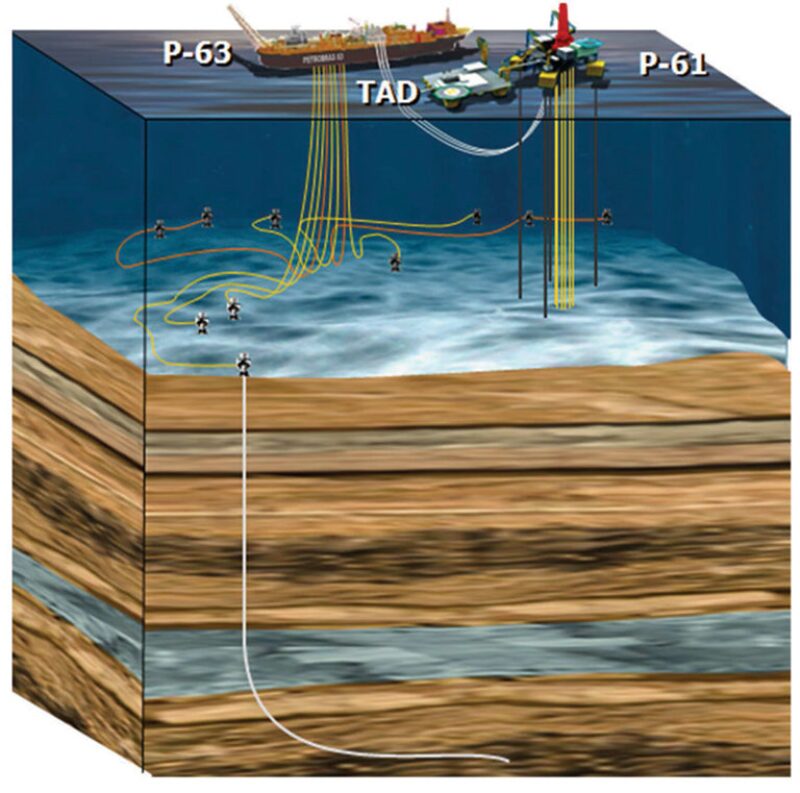

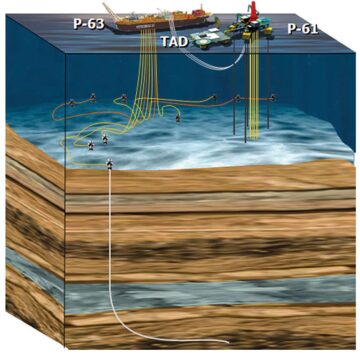

This led Petrobras to a field--development concept that uses two production units, an FPSO (P-63) and a TLWP (P-61), 350 m apart.

The P-61 platform will be connected with 13 dry-completion wells, and all production will be exported to P-63, where it will be joined with the production from five wet-completion wells to be processed. The TLWP will not have a process plant to separate oil, gas, and water and will transfer all produced fluids to FPSO P-63 through multiphase pumps.

As a secondary recovery method, 10 injector wells will be placed at the reservoir extremities to maintain pressure in the reservoir (Fig. 1).

As a consequence of this development, and mainly because of the oil properties, the items that needed to be developed to make the project technically viable and economical attractive are

- High-power ESP

- TLWP as a production unit

- Conductor-driven installation

- Thermal-insulated TLWP risers

- Tender-assisted drilling (TAD) unit

- Fluid-transfer lines at midwater

- Electrical-heated flexible pipe

High-Power ESP

The high expected and needed flow rates and the known inefficiency of gas lift with such high-viscosity oils led the Papa-Terra project team to decide to complete all 18 production wells with high-power tubing-mounted ESP.

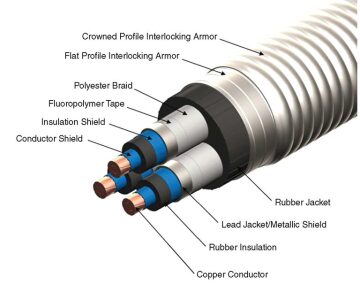

Because of the high load required to restart the production wells, all electrical power systems are rated to 5/8 kV. Thus, in case of ground failure, it is not necessary to reduce the operating frequency to meet the phase-ground voltage class in the unbalanced electrical power system. This premise led to the development of a new round cable (Fig. 2).

TLWP as a Production Unit

Thirteen of the 18 production wells are going to be connected to the TLWP (P-61) unit. The main reason for choosing the TLWP as a production unit was to increase the availability of ESP change operations by considering workover facilities at the TLWP topside and to avoid the dynamic-positioning rig’s higher daily rates that are commonly required on this kind of operation. With this choice, all interventions in the wells are made though the TLWP, while the other wells still produce without interference.

Conductor-Driven Installation

The TLWP installation brought the challenge of how to attend to the wells’ first phase with positioning and ESP installation and intervention through the risers.

The acceptable installation error of the design conditions was established as 0.3 m around the wellhead centerline with a maximum tilt of 1°. A maximum dogleg installing the ESP was considered to be 3° for every 30 m of casing.

To withstand the extreme loads applied by the TLWP at the wellhead on the seabed, a first-phase (conductor-casing) depth target was fixed at 55.6 m with a 36-in. conductor and a length of 57 m.

Considering these boundary conditions, the conductors had to be designed and installed as a single piece to meet the load requirements. In order to achieve the position and tilt requirements, the conductor installation was performed by using subsea templates as guides and a hydraulic hammer to drive the conductor casings installation and achieve target depth. The templates were designed to be recovered after the conductor casing installation so they would not interfere with conductor movement caused by TLWP offset.

Insulated TLWP Risers

In addition to downhole ESPs, chemical injection points, permanent downhole gauges (PDGs), and downhole safety valves (DHSVs) were also required on production tubing.

For this reason, the production risers were designed to have the following inside their annuli:

- ESP electricity supply cable

- Three chemical-injection lines

- Two hydraulic control lines for DHSV activation

- PDG cable

During shutdown situations, the oil viscosity is likely to increase as the oil temperature drops inside the production tubing. To avoid this, the TLWP riser was designed with thermal insulation to increase the no-touch time for the riser -fluids, during which no action is required by the operation team. The thermal insulation contains a 2-in.-thick layer with a maximum thermal conductivity of 0.17 W/m·K, with nitrogen gas at a low pressure inside the annulus to decrease heat loss.

With the additional insulation, an increase in viscosity is not expected to interfere with ESP restart within 12 hours of shutdown. If a shutdown of longer than 12 hours is expected, procedures call for bullheading with diesel to displace all production fluids inside the production tubing pumping fluid back to the reservoir.

TAD Unit

To reduce investment costs while still taking advantage of dry completion, the decision was made that the P-61 TLWP would only have workover facilities. To aid with drilling necessities, a TAD unit was moored close to the TLWP. The TAD unit that will be used in Papa-Terra will be responsible for assembling the master equipment package and providing all of the drilling and completion equipment necessary after the TLWP installation. The TAD unit will be uninstalled once the drilling operations at the TLWP are completed.

Fluid-Transfer Lines

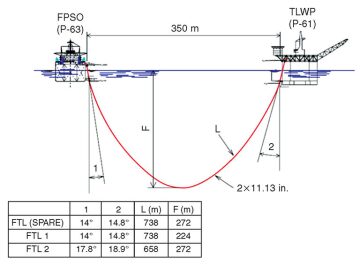

Because the P-61 TLWP is not designed to process produced fluids and is not capable of storing oil, all produced fluids will be transferred to the FPSO vessel, which will process and store the fluid waiting to be offloaded.

Boundary conditions for this flow to the FPSO vessel dictate that the internal fluid temperature not drop below the point where the high viscosity of the fluids would lead to excessive or even unfeasible discharge pressure for the multiphase pumps.

To solve this problem, the project team decided to decrease the distance between the TLWP and the FPSO vessel so that the fluid-transfer lines would not touch the seabed and, consequently, not be exposed to the low temperatures found on the sea bottom. For this, the fluid-transfer lines were configured as high-thermal-insulated flexible pipe in double catenary configuration at midwater (Fig. 3).

To handle the projected flow rates, two flexible pipes with inner diameters of 11.13 in. are planned.

Electrical-Heated Flexible Pipe

The wet-completed production wells will be connected to P-63 with flexible pipe and an electrical heating and temperature monitoring system. The monitoring system aims to mitigate production loss in heavy-oil fields in deep water from risks involved in production restart.

Especially for the Papa-Terra field, production restart procedures regarding ESP startup need to be conducted carefully in order to reach the appropriate flow rate to cool off ESP drivers inside the wells. If this condition is not met, ESPs could fail because of motor overheating. Furthermore, cool-down times are not long enough to proceed with fluids displacement feasibly, jeopardizing production restart.

The electrical-heated flexible line has an ordinary rough-bore flexible pipe at the inner layers and an outer bundle with electric cables to heat the pipeline, optical fiber to monitor the temperature, and a thermal insulation layer to minimize heat transfer to the external environment.

This article, written by Special Publications Editor Adam Wilson, contains highlights of paper OTC 24504, “Papa-Terra Project: Use of Innovative Solutions for Heavy Oil in Deep Water,” by D.S. Condessa, G.S. Damno, S.C. Vieira, and W.P. Goncalves, Petrobras, prepared for the 2013 Offshore Technology Conference Brasil, Rio de Janeiro, Brazil, 29–31 October. The paper has not been peer reviewed. Copyright 2013 Offshore Technology Conference. Reproduced by permission.