Hydraulic Fracturing Content Feed

-

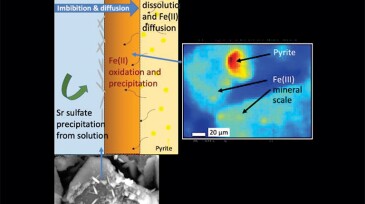

The obsession with better hydraulic fracturing has steadily pushed on shale production in year one, but the decline remains steep. Chemistry could help explain, and perhaps extend, the short productive life of these wells.

-

SponsoredExtended reach wells provide access to otherwise inaccessible areas, improve production and reduce footprint. Advancements in completion technology allow producers to eliminate coiled tubing, perforation guns and milling out operations to lower project risks, costs, and environmental impact.

-

Incremental gains are not always celebrated, but as two of the biggest oil producers in the US show, they nonetheless can net unrealized savings and new efficiencies.

-

The combined company will have a strengthened position in the Permian Basin, and plans to operate 17 hydraulic fracturing fleets in the region.

-

SponsoredAmong the industry’s shortest and most advanced dissolvable frac plugs, Stinger delivered big to this Howard County, TX operator with time and cost savings.

-

SponsoredAmong the industry’s shortest and most advanced dissolvable frac plugs, Stinger delivered big to this Howard County, TX operator with time and cost savings.

-

A 2-year study of a formation used for saltwater disposal in the Bakken may hold promise of decreasing the pressurization of the formation and increasing the reuse of the briny produced water.

-

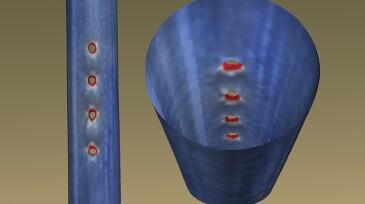

When fracturing, simply shooting all the perforations at the same spot in the casing can offer increased production at a low cost.

-

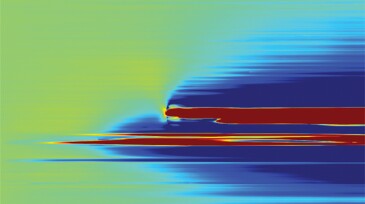

This study in a shale-oil formation quantified the hydraulic fracture propagation process and described the fracture geometry by developing a geomechanical forward model and a Green’s function-based inversion model for low-frequency distributed acoustic sensing data interpretation, substantially enhancing the value of the LF-DAS data in the process.

-

SponsoredHigh-resolution optical measurements hold the key to unlocking the performance of hydraulically fractured wells