Methane emissions from the oil and gas industry are receiving intense scrutiny as part of the energy transition. A large portion of the methane emissions from upstream and downstream operations arises from a small number of large emission events. These emissions originate from a variety of sites, and recent data suggest many emission events are intermittent. Currently, no way exists to predict facilities likely to release large quantities of methane, and, thus, all sites along the upstream production network must be monitored. Continuous monitoring using methane-emissions detectors installed permanently at a site offers an effective way to identify, quantify, and repair intermittent emissions.

Installing emissions detectors across many diverse sites, however, can be economically challenging. The authors of this paper describe a cost-optimized, continuous, methane-emissions detector connected through Internet of Things (IoT) technology and capable of being economically deployed on a large scale.

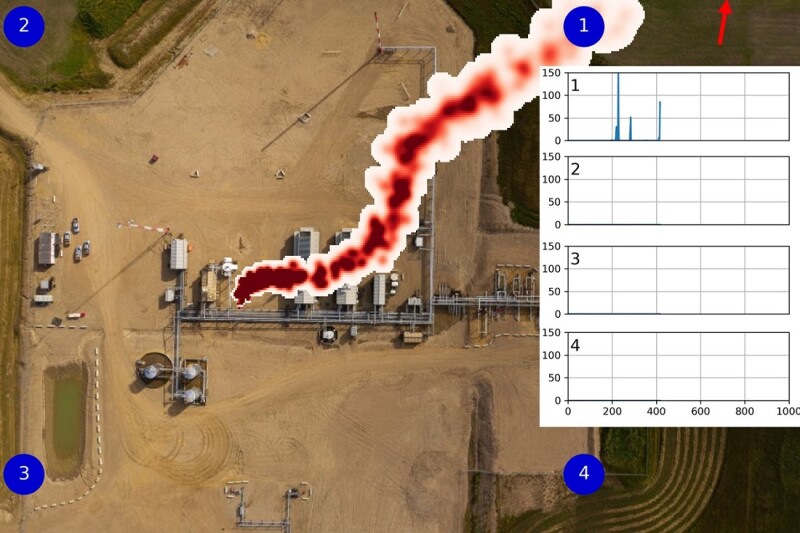

The continuous methane emissions monitoring system is based on a small number of IoT-enabled, fixed-location methane sensors located at the boundaries of each facility (Fig. 1). The detectors simultaneously collect measurements of methane concentrations and meteorological conditions, such as wind speed and direction, over time. These recordings first are filtered and averaged by use of edge computing through a procedure informed by existing knowledge of methane dispersion in a typical wind temporal spectrum to ensure that only high-quality and stable measurements are used. The data then are sent via a secure gateway to an interpretation cloud platform, where they are inverted based on a suitable Gaussian plume dispersion model to confirm the existence of a leak, its position, and the emissions rate.

Each of these components is described in more detail in the complete paper. Further, the paper presents the performance of the full system through testing at a facility that can generate known methane releases.