Monthly Features

-

This article is the fourth in a Q&A series from the SPE Research and Development Technical Section focusing on emerging energy technologies. In this piece, David Reid, the CTO and CMO for NOV, discusses the evolution and current state of automated drilling systems.

-

Casing deformation has emerged as a major challenge in China’s unconventional oil and gas fields, prompting the development of new solutions to address the issue.

-

Oil and gas experts encourage human/AI partnerships that can “supercharge” capabilities to create competitive advantages.

-

The US supermajor is using one of its lowest-value hydrocarbon products to generate double-digit production increases in its most prolific US asset.

-

The use of real-time wireless downhole pressure gauges proved a valuable alternative to workover operations in two onshore fields in Iraq.

-

Bad vibes are being addressed by contractors as operators push to go faster, deeper, and longer with unconventional wells.

-

The SPE International Awards honor members whose outstanding contributions to SPE and the petroleum industry merit special distinction. Recipients of the 2020 International Awards will be recognized during the Annual Technical Conference and Exhibition.

-

The SPE International Awards honor members whose outstanding contributions to SPE and the petroleum industry merit special distinction. Recipients of the 2020 International Awards will be recognized during the Annual Technical Conference and Exhibition.

-

Brazil’s national oil company details the results of 6 years of real-time drilling monitoring. The next step is to move toward optimization, then automation.

-

Discussed are real-world examples of the less often considered but valuable environmental benefits delivered via MPD.

-

The E&P subsurface sector today faces the lowest reserve replacement ratios in decades as well as an increasing need to maximize recoverable oil and gas from developed fields.

-

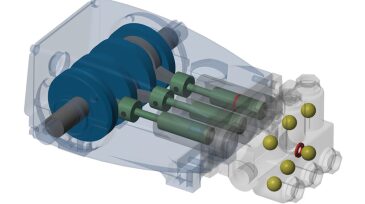

Often it is too difficult to create the fault conditions necessary for training a predictive maintenance algorithm on the actual machine. A digital twin generates simulated failure data, which can then be used to design a fault-detection algorithm.

-

A multizone water-injection project has ultimately proved a method of using intelligent completion interval-control valves in place of traditional sand-control completions in soft sand reservoirs.

-

An intelligent drilling optimization application performs as an adaptive autodriller. In the Marcellus Shale, ROP improved 61% and 39% and drilling performance, measured as hours on bottom, improved 25%.

-

The oil and gas industry is increasingly characterized by complex connectivity, but our digital dependency brings a new realm of cyber risks. Are we cyber-ready?

-

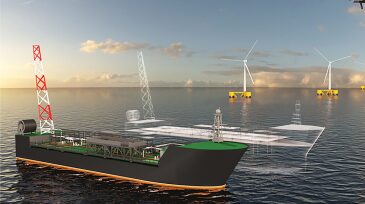

While it remains today only an idea, there are but a few barriers keeping an unmanned floater from being realized, according to one of the world’s leading offshore engineering firms.

Explore Content by Discipline

Power Up With JPT Newsletters

JPT Newsletter (Weekly).

All the top stories, trends, and tech.

JPT Unconventional Insights (Monthly).

Fresh takes on shale and tight oil.

Get JPT articles in your LinkedIn feed and stay current with oil and gas news and technology.