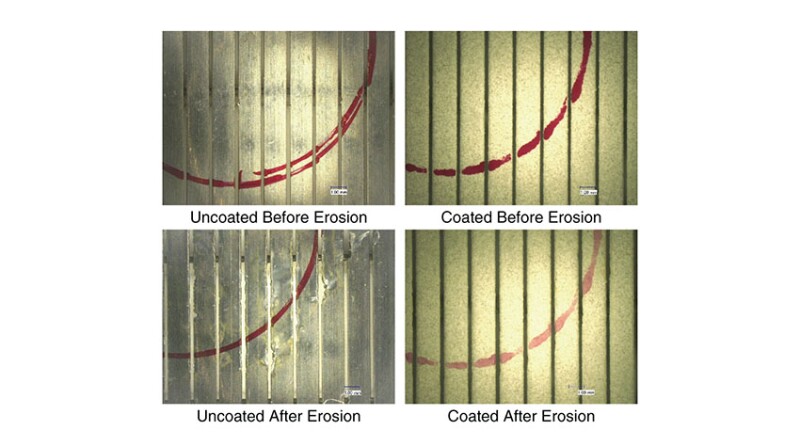

A newly developed coating is put on the outside (i.e., facing the formation) of standard wire-wrapped screens to make the slots erosion-resistant. The coating consists of ceramic or hard metal and is applied by plasma spraying. An extensive development and verification program was conducted to guarantee defined slot widths, corrosion resistance, and mechanical strength of coating and screen. The coating improves resistance against erosion, can withstand corrosive well environments, and features mechanical properties suitable to be safely installed in any well.

Thermal Spraying and Composition of Coatings

The screens are coated using thermal spraying.

×

Continue Reading with SPE Membership

SPE Members: Please sign in at the top of the page for access to this member-exclusive content. If you are not a member and you find JPT content valuable, we encourage you to become a part of the SPE member community to gain full access.