Robotic submarines, capable of operating by themselves thousands of feet underwater for months or perhaps years at a time, are under development as the vanguard of tomorrow’s subsea oil and gas fields. This development comes as the offshore oil and gas industry moves into ever-deeper waters and remote areas of the world, where installing a floating production facility is either economically unjustifiable or infeasible.

The industry’s solution is to install production equipment on the seafloor, where someone, or something, must keep a close eye on all of it. That something is likely to be what are known as field resident autonomous underwater vehicles (AUVs). Nonresident AUVs have already paved the way by proving they can carry out detailed inspections of platforms and pipelines in some cases four times faster than a human-piloted remotely operated vehicle (ROV). Two of the leading companies in the resident AUV business, Lockheed Martin and Saab Seaeye, are blending proven military technology with new software and hardware optimized for the offshore industry. Their emerging systems represent a new breed of subsea robots that will be capable of much more than earlier generations of autonomous systems. As their capabilities are realized, resident AUVs will eventually be assigned many of the same tasks that ROVs are carrying out today.

To achieve that end, offshore operators are working with manufacturers to identify how best to fully deploy this emerging technology. Much of the groundwork is being laid through DeepStar, a research and development consortium that counts 11 operating companies as members. “We are already using AUVs for certain functions on a sporadic basis, but we’re trying to understand, as operators, what else this technology can do reliably,” said Greg Kusinski, DeepStar director and Chevron senior advisor to DeepStar.

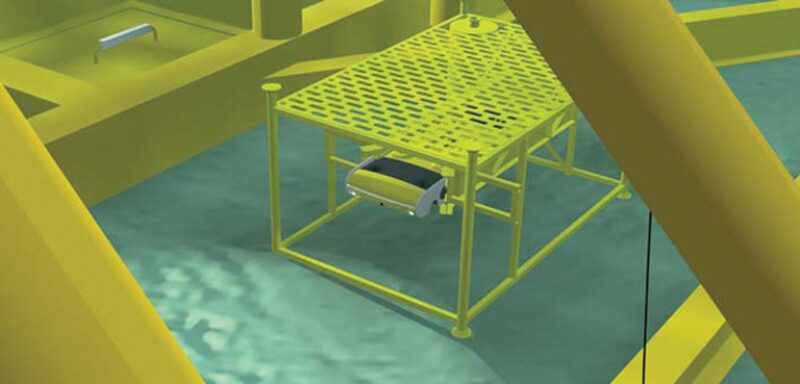

DeepStar’s primary goal is to accelerate the development and adoption of AUV technology by drafting interface standards, similar to the standards already developed for ROVs. Among the interface issues yet to be resolved is how resident AUVs will connect to life support systems in a subsea field. Because resident AUVs will have to remain submerged for months to possibly years at a time, the docking station is a critical piece of equipment that will charge up the AUV and upload its data to the operator’s server by a subsea Internet connection.

Once the particulars of the docking station are understood, Kusinski said careful consideration must be given to other issues, such as where to place it among the subsea infrastructure. “There are a lot of questions of that nature,” he said. “As responsible operators, we are addressing these issues in a very systematic and methodical manner. I don’t think anyone is interested in putting a bunch of them down there and just seeing what happens.” DeepStar expects to conclude its AUV study on interfaces in about a year and will deliver its recommended best practices to the American Petroleum Institute for review.

Resident Capabilities

Although AUVs have been used by the offshore industry for years, they have had very limited application until recently. One subset of AUVs called underwater gliders travel thousands of miles across the world’s oceans collecting oceanographic data for scientific research, but are not applicable to the deepwater environment. Torpedo-shaped AUVs can zip through the water at high speeds while conducting ultrahigh-resolution seismic surveying and mapping; however, they lack the maneuverability to conduct the close inspection, sensor replacement, and valve operations a subsea production facility would demand. Human-piloted ROVs are not the answer either as they were designed to stay underwater for only hours at a time, not days, weeks, or months.

A resident AUV must be able to hover in place or move in any direction. It must also have an onboard collision avoidance system that will prevent it from striking environmental hazards or production systems on the seafloor. “We have standardized what kind of forces and momentum an ROV can carry into infrastructure from an impact perspective,” Kusinski said. “Now we are thinking about that from an AUV perspective, and since they are smaller, we could potentially allow them to travel faster.” ROVs are restricted in terms of speed for other reasons too. A typical ROV must move as slow as half a knot (kn) to properly manage its tether system and allow the surface vessel to follow it from location to location, whereas a resident AUV moves as fast as 6 kn because it works independently.

And unlike a work-class ROV, to deploy an AUV, operators do not need to contract a dynamically positioned support vessel. Day rates for this type of vessel, which in many cases are at least 300 ft in length and house up to 100 crew members, run as high as USD 250,000. Large vessels are needed because an ROV comes with a large equipment spread that includes a tether management system, winches, a control van, and replacement parts that together can weigh up to 90 tons. In contrast, an AUV can be launched and recovered from a significantly smaller vessel because it comes with a small amount of supporting equipment and without a tether, dynamic positioning is not needed.

Additionally, work-class ROVs require an onboard team of pilots and technicians to operate the vehicles and repair them when they break down. In contrast, when an AUV hits the water, it begins its mission without the need for human interaction until it resurfaces. Customized operations can be preprogrammed into the AUV telling it what to do in certain situations and new commands can be uploaded to its software while submerged. Another important distinction is that AUVs are less prone to mechanical failure because they have fewer moving parts than an ROV and no hydraulic systems.

With these advantages in mind, AUV makers are hoping that in the not-too-distant future, oil and gas companies will not only see AUVs as more competitive than ROVs, but also as a required asset for life-of-field operations. “Field operators have very high standards,” John Jacobson, senior program manager at Lockheed Martin, said. “The infrastructure is extremely expensive and it is carrying product. So as we work toward these capabilities, we have to keep in mind the standards that operators will put upon the AUV in terms of performance, reliability, and navigation.”

Deepwater AUV

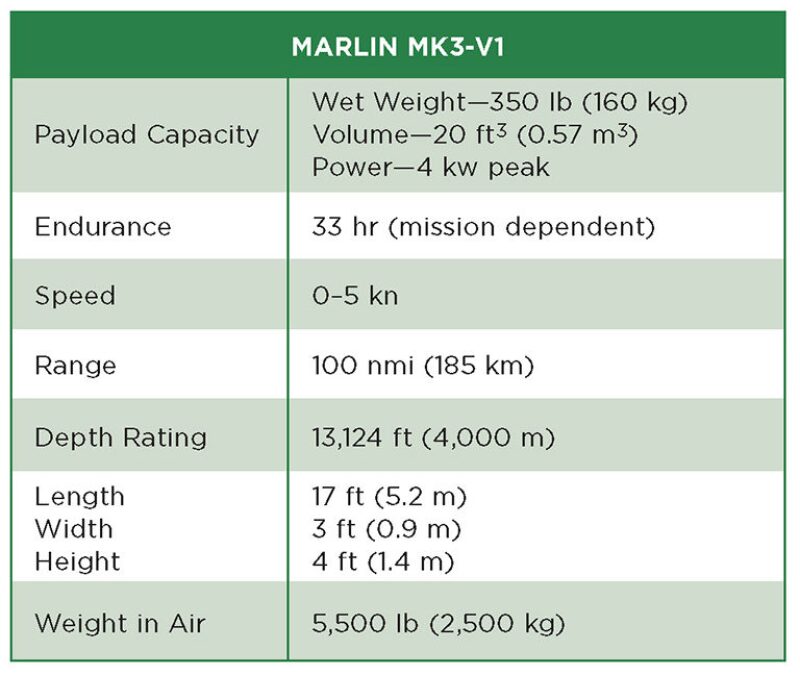

Lockheed Martin is applying AUV technology that it originally developed for military applications to now meet the needs of the deepwater oil and gas market. The company’s latest development is a deepwater AUV called the Marlin Mk3, which is capable of operating at depths of up to 13,100 ft (4000 m) for up to 33 hours on a single battery charge. Based on a field-tested model engineered for shallower depths, the deepwater Marlin is in its late-stage design phase. The future vision of the program is to develop a highly functional resident system that operators can rely upon for inspection and light intervention work.

To guide its way through the dark depths, the Marlin employs several navigation systems, including an inertial measurement unit coupled with Doppler sonar. “We enhance that using other features, including terrain- and feature-based navigation,” Dan McLeod, deputy director of offshore systems and sensors at Lockheed Martin, said. The Marlin’s software enables it to identify not only seabed hazards, such as boulders or steep inclines, but also specific equipment, such as manifolds and subsea trees. Once georegistered, the AUV will never forget the location of the equipment, or the features of the surrounding terrain.

In order to withstand the pressures of the ultradeep, the latest Marlin will have stronger pressure vessels to protect its electronic and mechanical systems. To achieve buoyancy, the deepwater AUV will use a denser form of the synthetic flotation material used in the earlier models. As a result, the 17-ft-long deepwater Marlin is more than twice the length and weight of the first generation AUV designed to operate at a maximum depth of only 1,000 ft (304 m). “By necessity,” McLeod said, “deeper vehicles get larger and heavier.”

Another key difference between the earlier version and the deepwater model is that it will be equipped with interchangeable payload modules. Lockheed Martin believes that a modular design provides the ability to tailor the AUV with regard to how much endurance vs. sensor capacity each mission calls for. “On one mission, you might need more battery and less work payload, and on another mission, you may need less battery and more payload,” Jacobson said. “And we’re anticipating that you are going to want to change things out, that you are going to want to take on the latest sensors.”

Change Detection

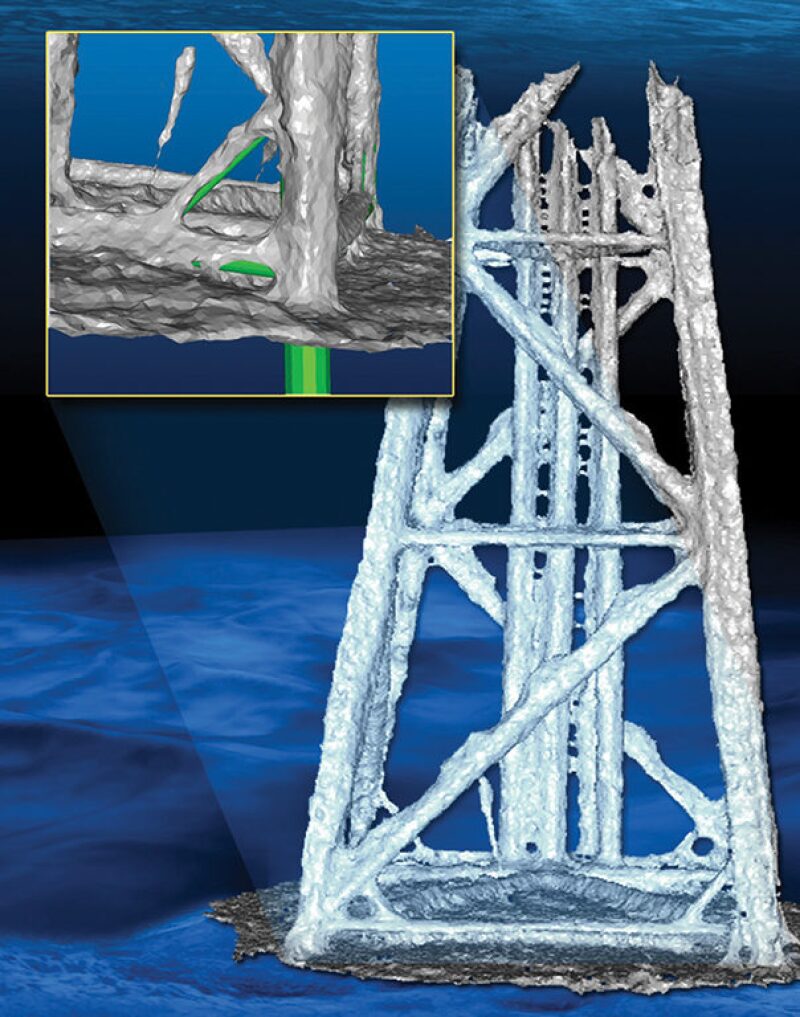

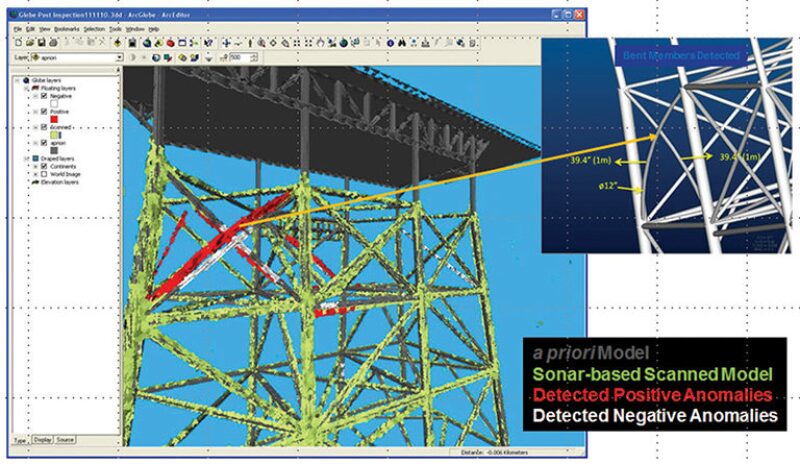

Among the modular systems that Lockheed Martin is planning on equipping the Marlin with is a 3D laser scanner. Current 3D imaging is done using sonar; however, even the latest sonar technology is limited by the physics of sound and only capable of resolutions with about 5 cm of detail. Using a laser, “you are seeing 5-mm sorts of resolution, so it is about an order of magnitude improved,” Jacobson said. With this level of precision, the AUV is capable of measuring the exact dimensions of subsea equipment, comparing the measurement data with a baseline 3D model stored in its internal memory, and then detecting any changes, or damage, between the two.

Over time, the AUV builds up an inspection inventory that it will use to detect subtle changes that may go unnoticed using conventional inspection technology. “Today, ROV companies pay operators to sit and stare at screens for hours and hours on end,” Jacobson said. “That is a lot of manpower and those people get tired, and when people get tired, they miss things.” The AUV, he added, does not get tired, nor does it require a crew change.

While carrying out an autonomous inspection, the Marlin will use its high-definition video and still cameras, along with sonar or laser sensors, to record images of the systems and structures it is checking on. “What it is doing at the same time is detecting changes and flagging the operator,” Jacobson said. Preset commands tell the AUV that when it detects a change, however small or large, to investigate the problem further by getting closer to take photos, video, and detailed scans from multiple angles. “There might be 2 days of video, but does the operator have to watch 2 days of video to be cued up to what the significant issues are? Not necessarily,” he said. With the automatic flagging system, inspection engineers can skip over the innocuous and fast forward to where the problems have already been identified by the AUV’s software.

In 2011, Lockheed Martin and Chevron completed a series of demonstrations in the Gulf of Mexico of the shallow-water Marlin’s change detection software. Then in 2012, Chevron field-tested Lockheed Martin’s real-time 3D georeference model-building software, again with the shallow-water Marlin, to inspect 14 offshore sites in the Gulf of Mexico, including 11 standing structures. Over the course of the 2-week operation, the AUV was in the water for a total of 62 hr and covered nearly 76 miles in depths up to 125 ft (38 m). It took less than a day to download the data and generate 3D models of each of the structures.

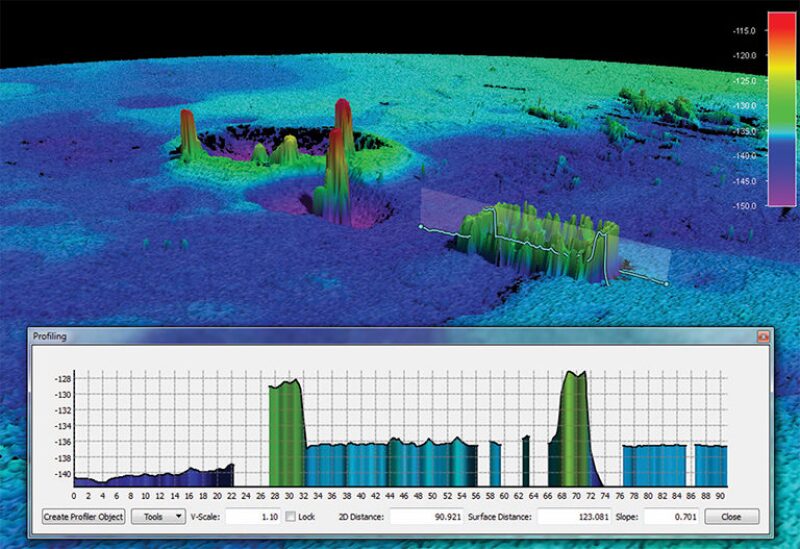

The Marlin’s change detection technology is also designed to monitor flowlines and pipelines that may have moved or become suspended across subsea berms. When production is starting up or shutting down, the temperature in the pipeline changes quickly. This can cause a thermal expansion or contraction of the pipe’s materials, which can then force entire sections to move out of place. This phenomenon, known as walking, can contribute to fatigue and serious failures at tiebacks and riser hookups.

Light Intervention

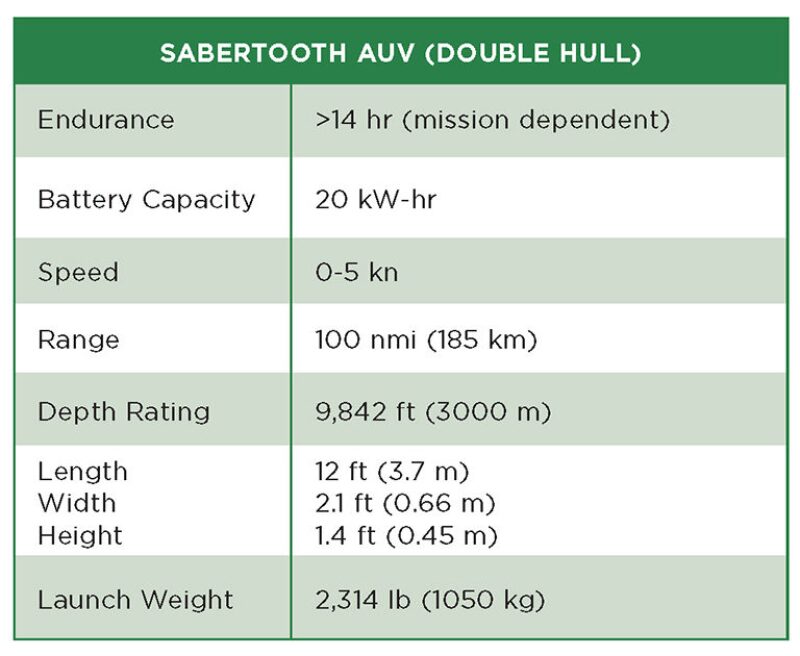

Like the Marlin, the underlying technology inside Saab Seaeye’s Sabertooth AUV is military born, originally conceived for hunting explosive mines and designed to carry a payload of sensors including cameras and sonar. The technology inside the Sabertooth was field proven, not in the deep waters of the US Gulf of Mexico or offshore Brazil, but high in the Rocky Mountains of Colorado. In 2011, Hibbard Inshore, an ROV company specializing in underwater industrial inspections, deployed the military version of the AUV in a 9-mile (15 km) water transportation tunnel used to supply water to a hydroelectric dam. Using the AUV, the customer incurred zero loss in revenue. “Traditionally, this operation was very expensive and difficult, because you had to drain the tunnels and that costs a fortune,” Jan Siesjö, chief engineer at Saab Seaeye, said.

The Sabertooth has an excursion range of about 25 miles (40 km) and can be depth rated up to 9,842 ft (3000 m) for deepwater operations. Subsea equipment maker Aker Solutions has partnered with Saab to fully integrate the technology with its subsea production systems. Aker has also completed design studies for a subsea control module for the Sabertooth’s docking station at which the AUV can power up and upload data in between missions.

One of the misconceptions that engineers are trying to put to rest is that AUVs are unequipped to operate the controls on a subsea system, which involves using a manipulator arm or a torque tool to turn various sockets and valves. The Sabertooth is among the first commercially available resident AUVs capable of these operations, termed light intervention. “People think they need hydraulic power,” Siesjö said regarding an AUV’s ability to operate valves. “You can actually do it just as well with a small electrical tool, but you need a vehicle with a high degree of maneuverability so you can be oriented to where you want to put the tool.”

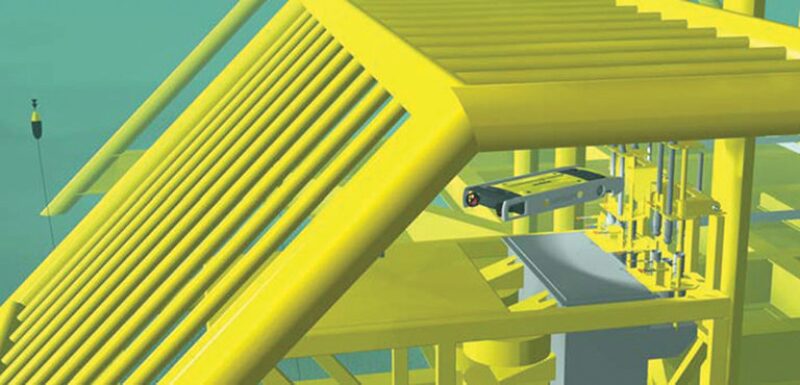

With this need in mind, the Sabertooth was designed to be very nimble, so that it can swim inside manifolds and underneath equipment for close inspection. Its thrusters and buoyant design allow it to pivot 360° on its axis and maintain its position at any angle, which means it can work facing straight up or straight down. Although the vehicle was designed to operate independent of human controllers, it is a hybrid system. If the vehicle is connected using a tether or radio link, it may be manually operated. When used as a resident system, the Sabertooth recharges itself in a protective docking station where the AUV can begin uploading sensor data, video, and sampling data to onshore using an Ethernet connection. Using a hydrophone, the Sabertooth is even able to listen for oil or gas leaks. If a leak is detected, the AUV can take up to four environmental samples and send the resulting analytic data back to the operator.

Several operating companies have shown interest in the Sabertooth, including Chevron, which sponsored a project in late 2012 to demonstrate the AUV’s data harvesting capabilities. During the tests, the AUV retrieved data wirelessly from a subsea sensor and then physically connected to the sensor to transfer data through a hard link.

The test determined the useful range of an aftermarket communication system and was carried out under both lake and open sea conditions. In another study, completed for Exxon-Mobil, the AUV’s reliability as a backup solution should an emergency occur in a remote subsea area, such as the Arctic where most support vessels are unsuited to operate during the winter months. “If you are in the Arctic and it is frozen all over,” Siesjö said, “when something happens, you need to be able to go out to find out what it was and possibly turn a valve to shut something down.” In Arctic scenarios, AUVs such as the Sabertooth could serve as early warning systems for the particularly real threat of ice scouring and could alert operators quickly about oil or gas leaks, or even shut in production. If the AUV is unequipped to remedy the problem right away, “you will always be in a situation where you will gain time, whether it be hours or days if you have something already there in the field that can go out and investigate for you,” Siesjö said.

Communications

Last year, the Sabertooth was tested by Eni Norway in the fjords just off Hammerfest, Norway, located more than 300 miles north of the Arctic Circle. During the test, the AUV used beams of blue photons to communicate with a seabed sensor at a distance of almost 200 ft (60 m). Called BlueComm, the technology was developed by Woods Hole Oceanographic Institution, the largest oceanographic research facility in the US. The institution partnered with Sonardyne, a subsea communications systems maker, to bring the system to the offshore industry.

Wireless optical systems, such as BlueComm, will be used to establish an infield communication network between various subsea production systems, vessels, and AUVs. BlueComm transmitting and receiving units installed on an AUV and on subsea sensors can share data at a rate of more than 20 MB/s across almost 500 ft (150 m) of seawater. This broadband data stream allows operators to receive high-definition video in real time when the system is integrated with a sea-to-shore link.

The technology is an evolutionary leap for subsea communications that for more than 40 years has relied on acoustic sound waves to transmit much smaller bits of data. “With acoustics, we can transmit about 6 kB of data, which is pretty fast,” Ralph Gall, technical sales manager at Sonardyne, said. “Six kB is a lot, but 20 MB is massive and gives you the ability to send video over 150 m, which is a big deal in the subsea.”

The technology also applies to data harvesting and significantly reduces the time it takes to upload data compared with current technology. With an optical communication system, sensors and AUVs that have been logging data for long periods of time, but are not connected to a subsea Internet, can upload gigabytes of information in minutes to a visiting surface vessel equipped with a lower bandwidth commutation system. By lowering a communications device known as a depressor equipped with a receiver unit on its end, vessels and crews would not be required to spend valuable time at sea physically recovering the AUV or sensors, downloading the data, and then redeploying each system.

Saab Seaye is also testing other ways of communicating, such as electromagnetic antennas and short communications tethers. Electromagnetic communication has been used by various branches of the military in both underwater and underground scenarios. Using this technology, the antenna can be built into the AUV and allow for high bandwidth communication rates as high as 10 MB/s when the vehicle is in close proximity to a docking station. Other companies are also working to solve problems that will expand the applications of AUVs even further, such as how to communicate through layers of ice and improve the redundancy of subsea communication networks to make the vehicles more efficient and safe.