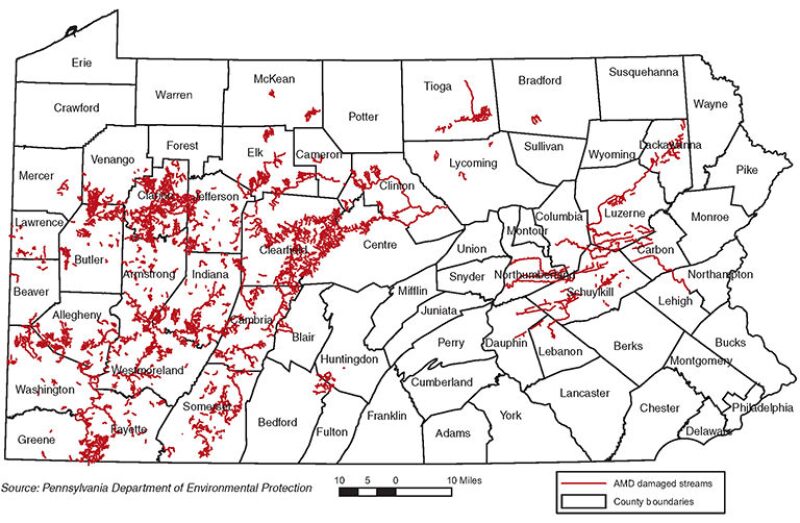

There are more than 4,000 miles of rivers and creeks in Pennsylvania damaged as a result of the water draining out of abandoned coal mines. The orange-tinted water and rust-colored rocks are reminders of the damage going on since the days Pennsylvania mines powered the United States’ rise as a global industrial power.

Now producing natural gas by fracturing, the Marcellus shale is driving the state’s economy and those dead streams could present an unusual opportunity: offering both a source of much-needed water and a way to help clean up of waterways polluted by coal mine waste.

There is an exploration and production (E&P) company in the state, Seneca Resources, using the abandoned mine drainage (AMD) water for fracturing. By pumping as much as 500,000 gal/D of water from an old coal mine with low levels of sulfates, iron, and often other metals, it can improve the quality of the water downstream by taking those things out.

“There are a lot of opportunities in the southwestern part of the state,” because there are so many flooded old mine shafts draining into waterways, said Doug Kepler, vice president of the environmental engineering group at Seneca Resources. “There is a lot of activity. A lot of operators are looking into whether they can do that.”

Water used by Seneca requires little treatment because the sulfate and iron levels are low, but that is the exception in Pennsylvania, where chemicals leached from the water in old coal mines and from mining waste heaps can create metal-laden, acidic water that is deadly to fish, insects, and plant life in rivers.

While many E&P companies are interested in AMD water for fracturing, there are technical and legal obstacles to overcome.

Treatment methods are needed for water that is often highly acidic, loaded with sulfates, and high in iron or other metals. The cost of that water has to be competitive with relatively inexpensive freshwater sources, and that amount must cover the cost of disposal of any byproducts. And environmental regulators need to answer a critical question: If an oil company uses mine drainage for a time as a source of water for fracturing, will it be responsible for that water source forever?

The state has said it supports the use of AMD for fracturing, and Pennsylvania environmental regulators have supported a bill limiting liability for AMD use by the oil industry. The US Environmental Protection Agency has remained mute on liability questions related to AMD use, said Tom Gray, energy and natural resources manager at Tetra Tech, who delivered a presentation on the advantages of using mine water for fracturing. “To my knowledge, the EPA has never provided a direct written response.”

The Color of Trouble

Billions of gallons of water a year flow out of the mines into creeks, turning them a distinctive orange or yellow shade, showing iron is present. It was a problem here long before the Marcellus shale boom, and will remain one long after it ends.

“Some of the older people who were children during the 1920s and 1930s have always known creeks to be orange. They did not know anything different,” said Andy McAllister, regional coordinator for the Western Pennsylvania Coalition for Abandoned Mine Reclamation. “One hundred years ago, when people were looking for a place to live, they looked for an orange creek. That meant there was a coal mine nearby and there would be work.”

The nonprofit group is one of many working to improve water quality by making the most of federal, state, and private money, which provides a fraction of the estimated USD 14 billion cleanup cost, McAllister said. Much of the problem is due to mines abandoned before passage of a US law passed in 1977 that required mine owners to set aside money to cover the cost of caring for the land after mining ends.

While the problem is worse in Pennsylvania, it exists in other US states with a history of mining, including West Virginia, Colorado, and Oklahoma, where there is a project to see if mine water can be reused, he said. In terms of community relations, using water from abandoned mines looks like a perfect fit in a place where hydraulic fracturing has been a point of contention.

Oil and gas operators would like to be associated with helping improve water quality, but there are problems to solve to ensure they can get the water quality and price needed when pumping millions of gallons of water per completion.

Chemical treatments exist to remove metals, but it is far more difficult to get rid of sulfates, which can combine with minerals in the Marcellus, such as barium, to produce tough, production-reducing scale. And there is a legal question to answer as well. While oil and gas producers would like to help clean waterways, they do not want to be held liable for perpetual care of mine runoff.

The rewards associated with finding a way to use AMD for fracturing have inspired researchers to look for cost-effective ways to treat the water, oil companies to consider how to use AMD, and watershed management groups to seek out oil industry partnerships.

Some are looking for markets for water treatment byproducts. A company recently created by Battelle, Winner Water Services, is commercializing a system to turn mine drainage into fresh water for fracturing. It is working with local E&P companies and is seeking markets for the chemicals it removes and also those it produces from the metals.

At the University of Pittsburgh, researchers have shown it is possible to remove sulfates from mine water and minerals in produced water by combining the two. It has found ways to speed the process and make it more efficient. But there is the problem of disposing of the solids left behind.

A large coal company, Consol Energy, which recently sold about half its coal mines to fund its growing gas E&P business, is seeking ways to process AMD water for reuse. According to the company’s website, it formed a water division in 2012 to “develop water-related services, evaluate emerging treatment technologies, champion the reuse of treated mine water.”

And there are E&P companies such as Seneca Resources using water flowing from mines instead of fresh water for fracturing.

No one has an estimate of how much mine water is being reused, but it appears small next to the magnitude of the mine drainage.

AMD’s Multiple Meanings

The acronym AMD is used for different phrases. The most common is acid mine drainage because much of it is highly acidic. Kepler prefers abandoned mine drainage because the pH runs from acid to alkaline, and what Seneca uses is nearly neutral.

The biggest source of trouble is iron pyrite found in seams of high-sulfur coal. The combination of water and air exposure causes the iron pyrite to disassociate, forming acid and often metals that leach into the flooded mine. Enough of this acidic brew flows out of old mine shifts into streams to shift the chemistry from near neutral (pH of 6.5 to 7) to acidic enough to kill fish (pH of 2 to 3).

When the sulfur in the iron pyrite combines with oxygen to form sulfuric acid, it leaves iron in the water where it colors the water and coats the streambed. In some places, the acidic water frees alumina from the coal, which creates an oxide that leaves a deadly bluish-white coating in some streambeds.

The concentration of mines in western Pennsylvania makes it the best match for using AMD in hydraulic fracturing. But no operator wants to fracture a well with sulfate-laden water. Sulfates can lead to production-reducing scale. Also free iron can interfere with chemicals in fracturing formulas.

There are widely used treatments for addressing AMD, ranging from passive treatment systems in which limestone in a retention pond reduces the acidity and compost promotes bacteria that consume sulfates, to water treatment chemicals used in active treatment systems that react with metals, causing them to precipitate out.

Passive systems help the environment by improving the water quality, but lack the high-volume and predictable water quality required by operators. Buying chemicals and disposing of waste push the cost beyond the cost of fresh water in many parts of the state.

For the oil industry there are potentially large risks and rewards associated with AMD. Operators are being courted by nonprofit watershed restoration groups that need partners with money to aid their underfunded efforts.

Old coal mines are not plugged and abandoned. Water naturally seeps out the old mine tunnels, which were mined uphill (updip) to allow gravity drainage, Gray said. Those designs that reduced the cost of pumping when mines were active now increase the flow out of abandoned mines.

The passive water systems used by water cleanup groups to treat that mine drainage require regular repairs and maintenance. When looking for support, McAllister said oil and gas companies are dealing with people living around yellow creeks that are a reminder of the damage done by a previous generation of energy production.

What is ancient history for those who came to produce gas from the Marcellus is the latest chapter in a long history for locals who live with environmental problems dating back a century or more. Back then, coal mining was booming and the oil industry was born in a state where there are thousands of abandoned oil wells with no record of their location.

“It is not just about technology. It is not just about money, it is not just about jobs. You have to look at the community you are dealing with the past,” McAllister said. “The company would do what it wanted to do and then it left.”

Monetizing Mine Drainage

Winner Water Services is working on perfecting a way to turn polluted water from mines into salable products. The company has shown it can convert acid mine drainage (AMD) into fresh water and chemicals for sale without any waste.

The next step for the company created by Battelle is to build a larger processing unit, able to run 100 gal/min and find markets to sell the chemicals it makes to cover the cost of the operation.

“What Battelle did is develop a treatment for remediation of acid mine drainage,” said Ann E. Lane, program manager of water-related technologies at Battelle. “It is able to remove both problem metals in impaired water and sulfates down to the level allowed by the EPA for discharge” into waterways. Grants from the US Department of Energy and the state of Pennsylvania support the effort to commercialize the process.

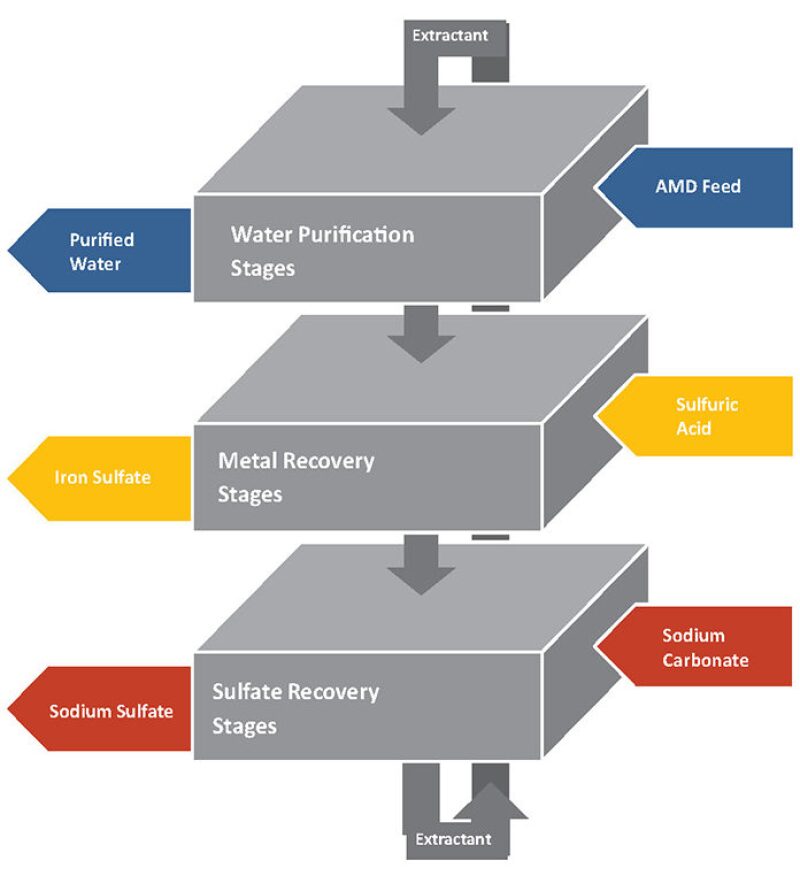

The process can be broken down into three stages, with about 10 steps, Lane said. Battelle developed a version of liquid/liquid extraction, which has long been used for recovering valuable metals from mines.

In the first stage, a chemical produced later in the process is used to remove sulfate, iron, aluminum, and other -metals from the AMD water. Lane said it takes about 40 minutes to produce fresh water equal to about 95% of the original volume. What started as acidic water (pH 3 to 4) will leave as nearly -neutral, with less than 100 ppm of sulfates and 1 ppm of iron.

The iron- and sulfate-rich mix removed during the first stage is then treated using sulfuric acid to create an iron sulfate that can be used in water treatment, such as for removing barium and strontium in hard water.

Then the chemical mix removed in the second stage is combined with a caustic chemical (sodium carbonate) to produce sodium sulfate, which can be used in a variety of industrial processes, such as producing laundry detergent, glass, and paper. What is left after the sodium sulfate is removed is the chemical used in stage one, which is used again.

Winner is now working on creating a 100-gal/min unit, which is semiportable. It is designed to be moved in about 2 weeks, Lane said. Mobile facilities are needed so they can be located at drilling sites to limit the cost of water transport to the treatment facility.

Local markets for the fertilizer produced would also be a large plus, because it would reduce the cost of delivering the product. It also could be shipped in liquid form without the cost of drying the chemical, so it could be bagged for longer hauls.

Lane said they are looking for opportunities in parts of Pennsylvania, where water costs more for oil companies looking for fresh water for fracturing, and there are sources of AMD water nearby with the right chemical makeup for the process.

From Mine to Well

Seneca Resources has been able to use mine water to replace the fresh water it uses along with recycled water to fracture wells.

The company has fractured more than 75 wells in Tioga County in northern Pennsylvania using a mix of 75% abandoned mine drainage (AMD) water plus 25% recycled water, said Doug Kepler, vice president of the environmental engineering group at Seneca.

Little processing is required—it filters out small suspended solids using filtration—because of the quality of its abandoned mine drainage, which is barely acidic (pH 5 to 5.5) and has little iron, aluminum, or manganese.

Seneca spent 18 months studying to see if it could find a source of water for fracturing using water flowing from an abandoned coal mine, and getting permits. While concentrations of chemicals are low, Kepler said that by removing up to 500,000 gal/D of water with sulfate and minerals, it improves the water quality downstream.

The decision to use AMD required consideration of the potential liabilities. Kepler said that taking mine drainage out of the stream is no different from drawing out unpolluted water. There is a limit set on how much can be removed. It would be a tougher situation if the water was being treated and returned to a stream, because then it would need to meet strict quality standards, he said.

Water from the stream is piped to wellsites in Tioga County, where the level of fracturing water needed justifies building a line. Outside the county, Seneca seeks out other sources of what Kepler described as the lowest quality usable water.

When Seneca is done drilling nearby, Kepler said the company plans to partner with a local wildlife preservation organization to install and maintain a passive treatment system in which natural materials, such as compost and limestone, are used to improve water quality.

“The general consensus is it has improved water quality now,” Kepler said. “The big picture is the really consistent long-term gains will come when we put in a passive treatment system.”

Treatment in Perpetuity

Using abandoned mine drainage (AMD) for fracturing can reduce the damage this water can have on the environment for as long as it is needed to complete wells. But the source of the trouble will remain. “AMD is always going to be there. We use the term ‘in perpetuity,’ ” said Andy McAllister, regional coordinator of the Western Pennsylvania Coalition for Abandoned Mine Reclamation.

Water in the Earth seeps into old mine shafts, leaches out minerals, and ultimately flows into waterways. Groups such as the coalition use natural methods to treat the water; building retention ponds in which iron combines with oxygen in the air and settles out, limestone is added to reduce the acidity, and compost promotes bacteria that can reduce sulfates.

“There has been a lot of improvement,” due to the treatment systems installed reducing acid and metals in the water, McAllister said. But costly maintenance is required to remove the sludge left behind and to repair the damage caused by beavers and muskrats to the berms used to create these retention ponds.

Even a small chance that using mine drainage could lead to perpetual responsibility for a stream is the stuff of corporate liability nightmares. Lawmakers and regulators had to decide where to draw the line between holding mine owners responsible, and not frustrating watershed cleanup groups working to clean up problems that cost far more to treat than any government agency has been willing to spend.

“There is so much damage no one can entirely take care of this pollution problem,” McAllister said. Passive treatment systems can run from USD 250,000 to USD 1 million to build, he said, and the vast majority of the nonprofits building them do not have a fund for long-term maintenance.

In Pennsylvania, the state has passed a law to protect groups created to clean up polluted waterways. They are exempted under what is known as the Good Samaritan law—a reference to a biblical story about a man who aided a stranger in distress.

And oil and gas companies fall into a grey area between nonprofits cleaning up waterways and coal companies that are regulated because their mines can cause the problem.

The state’s government tried to reassure the industry in a 2011 white paper encouraging the use of what it called “mine-influenced water” discharged into Pennsylvania waterways. But oil companies would like something more specific, because they are worried about being held liable under the state’s tough Clean Streams Act.

“There is a white paper encouraging the use of AMD water. However, the feedback from the oil industry is they want something more specific, such as a supportive policy letter,” said Ann E. Lane, program manager of water-related technologies at Battelle, which is commercializing a water treatment technology it developed.

When asked about the state’s stance on oil company use of water, a spokesman for the Pennsylvania Department of Environmental Protection (DEP) said it has supported a state law that “would amend the Environmental Good Samaritan Act to provide relief for mine operators and water companies treating mine drainage from liability related to the use of the water at a well site.”

There have also been US federal court rulings that raise questions about whether an oil company using AMD water from a stream would need to comply with federal water regulations, McAllister said.

One possible way of sidestepping the risk would be partnerships. McAllister said the model could be water supply deals between companies and nonprofits, which would receive a donation to fund long-term AMD remediation in exchange for the right to withdraw treated water for fracturing. It follows an idea proposed in a white paper from Pennsylvania’s DEP on using AMD for fracturing.

“One potential solution is the establishment of trust funds to promote the ongoing treatment,” said McAllister. “This is not something DEP is mandating, but DEP believes discussion should be encouraged between the end users in the oil and gas industry and the mine-induced water (AMD) treatment plant facility operators, which may be nonprofit organizations or government entities.”