In a little more than a decade, the way water is supplied for fracturing in the Marcellus play has gone from “a truck with a hose in the creek” to “a massive industrial system” for water transport and treatment.

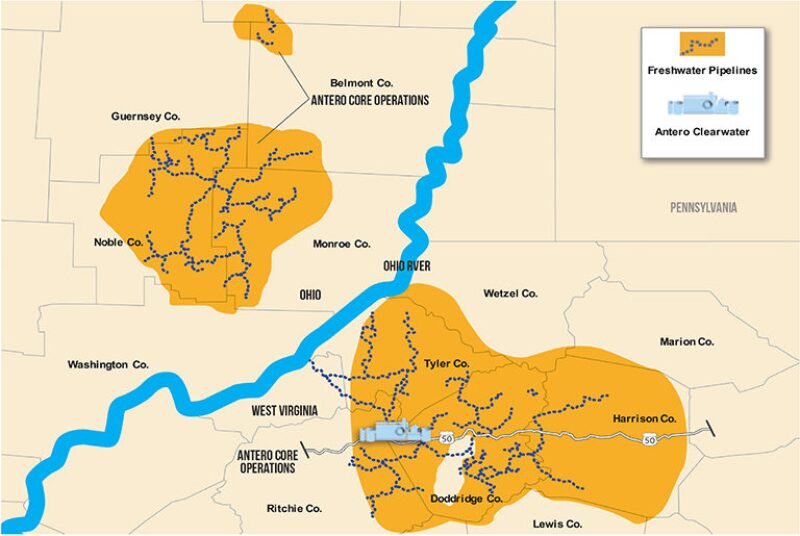

The description was offered by Conrad Baston, general manager of civil design for Antero Resources, who has played a key role in a major example of the change: a $750-million system to transport, store, and convert produced water into fresh water for use in its operations in West Virginia and Ohio.

The first stage was the most expensive—$500 million spent on 200 miles of buried and temporary pipelines to deliver fresh water for fracturing and 23 large freshwater impoundments to ensure a ready supply of water to fracture ever-longer horizontal wells. The water delivered by the system since 2014 would have required 1.4 million truck trips, and it has also reduced the volume of water drawn from local streams.

Stage 1 was part of a larger industry trend. What comes next is different. It is a one-of-a-kind $275-million plant that will convert 60,000 B/D of dirty, high-salinity water into fresh water and salt when it is fully operational next spring.

Produced water reuse has long been the norm in the Marcellus because of the high cost of wastewater injection well disposal. Operators have fractured wells using a mix of produced and fresh water. The produced water has been treated to remove those things that could damage the well. The formula varies depending on the operating company, but until now that has not usually included the dissolved solids, most of which are salt.

Antero’s Clearwater plant was built to treat water no municipal water treatment plant would touch, with salt levels many times greater than seawater along with heavy metals, hydrocarbons, and naturally occurring low-level radioactive materials. If it works as expected, the output will be water that meets West Virginia’s standard for discharge into waterways.

“Clearwater is really about getting rid of produced water,” said Alvyn Schopp, chief administrative officer and regional senior vice president for Antero.

At full capacity, the plant will produce 1.7 million gallons per day of water and about 2,000 tons per day of salt, which it plans to sell.

Clearwater could fill 25–30% of Antero’s water needs, Baston said. This will reduce the water drawn from local streams and ensure reliable water supplies during dry times.

Having the plant means Antero will be “able to keep drilling and keep drilling at the lowest cost,” Schopp said, adding, “Even without these things we are a low-cost producer. Now we think this will lower our cost.”

Moving only fresh water to fracturing sites reduces the risk of delivering water by pipelines in a place where “you have to go over a hill to get somewhere,” Schopp said.

If a landslide severs a pipeline with fresh water, the impact will be limited to erosion, he said.

Produced water is still going to be moved by truck, Schopp said. While a truck loaded with produced water is not without risk, the maximum one truck can spill is likely less than what can gush out of a severed 8–20-in. pipeline.

Salt Challenges

The startup process for the Clear-water plant began this summer, with a goal of reaching full-scale production by March.

In September, they were looking ahead to “making crystal.” Salt crystallization there uses a proprietary method developed by Veolia, reducing the energy required to boil the water when separating it from the dissolved salt. Multiple methods developed by Veolia, an international water treatment company, are used in the plant it designed and will run for Antero.

Veolia has a stake in the ultimate success of the plant. It will be running the plant under a 10-year contract that “gives us 97% uptime,” Schopp said.

The commissioning process for the plant follows the steps used for water processing:

- Pretreatment of the raw produced water to remove minerals, metals, and naturally occurring radioactive material (NORM).

- Thermal treatment where the brine is separated into fresh water and salt.

- Post-treatment where biological treatment removes any remaining contaminants.

The plant’s business plan requires it to successfully remove the low-level radioactive material, which will be shipped off to a hazardous waste facility. Sales of the sodium chloride and calcium chloride produced will begin after it certifies to buyers that the NORM has been removed, Schopp said.

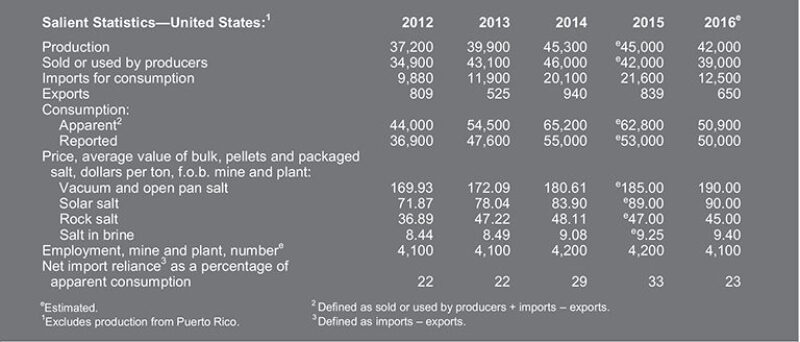

Salt sales will add revenue and avoid a monumental storage challenge. At its capacity of 60,000 B/D of produced water, the estimated output of salt will be more than 700,000 tons per year, or more than 1% of US salt consumption in 2016, according to the annual summary from the US Geological Service.

Antero is building a landfill near the plant for salt storage, but Baston has the job of finding markets for the salt and is looking for higher-value options, such as chemical makers.

The biggest potential market is road salt. Demand for the rock salt that is spread on pavement to prevent cars and people from slipping on ice represents 44% of US demand. This is a low-value use of salt and Clearwater’s production, which will be roughly equal to more than 3% of the road salt market in 2016, could affect the market.

Total road salt demand varies widely from year to year, depending on the severity of the winter. Sales are limited by concerns about salt damaging plant life and government spending limits.

Salt Uses:

- Highway de-icing accounted for about 44% of total salt consumed.

- Chemical industry accounted for about 36% of total salt sales, with salt in brine accounting for 88% of the salt used for chemical feedstock.

- Chlorine and caustic soda manufacturers were the main consumers within the chemical industry.

- Distributors, 8%

- Agricultural, 3%

- Food processing, 3%

- Other uses combined with exports, 3%

- General industrial, 2%

- Primary water treatment, 1%

Source: US Geological Survey.

Going First

Others in the Marcellus are watching what Antero is doing. In an industry where no one wants to go first, Antero will answer a lot of questions by going forward with something big that challenges the status quo.

“It is easy to drill another disposal well and jam it down there,” Schopp said. “It is not so easy to spend $500 million on freshwater pipelines and storage and [more than] $275 million on a plant.”

While the $750-million upfront cost of the water supply and treatment system looks staggering, this long-term investment is expected to save money on water needed for fracturing over many years. With 634,000 net acres of leases to develop, the water system will be needed for years to come.

Antero has the scale to take on this size project—it is the eighth-largest US gas producer—with liquids-rich production within a relatively concentrated area, making it possible to affordably transport water to and from the central facility. The plant’s processing capacity exceeds Antero’s current needs so it is also expected to generate revenue by processing other companies’ produced water.

The general outlines of the project appear to fulfil the requirements for a centralized facility that turns produced water into fresh water laid out in a recent paper (URTeC 2673999). That paper is based on a model created by Texas A&M University’s Global Petroleum Research Institute (GPRI) to compare various produced water options. The work began with the premise that the best option will vary depending on variables such as the transportation costs, water treatment costs, and water supply and demand.

But given the technical challenges, complexity, and the unknowns related to this new system, the paper warned that anyone considering such a project “should proceed with caution.” Antero’s plans address the concerns, but the questions cannot be finally answered until it has operating results.

While Antero and others in the Marcellus are trying new ways to lower water costs, the industry is short on tools to compare its produced water options.

The paper was written by Tyler Hussey, who developed a produced water economics model at GPRI called Upstream Water. He now works as an industrial water engineer for GHD, an engineering consulting firm that licensed the model, where he continues to develop the model which is used for water management planning.

The point of comparison in the model is the current cost of managing water. “Instead of trying to determine how much it might cost a company to treat and reuse water the water there, we set out to find how much it was costing a company to handle their existing produced water production,” said Hussey. That offers a clear benchmark for determining if doing something differently will really save money.

The problem has been that most companies “do not know how much they are paying to manage their water. No one wants to put a pencil to paper,” said David Burnett, director of technology for the GPRI, adding, “There is certainly a business out there.”

GHD will be incorporating the model into its existing water management programs. Burnett, who spent many years evaluating water treatment methods, said he is now focusing on identifying and promoting widely accepted measures and models so those managing oilfield water can identify problems and evaluate potential solutions.