Performance of CO2 injection relies on accurate CO2 minimum miscibility pressure (MMP) and miscibility data at reservoir conditions. A slim tube is the most-reliable tool to measure MMP under different miscibility mechanisms; however, it is very time- and capital-intensive, making it impossible to provide high-throughput data to assess the effect of other gases. Rising-bubble apparatus and vanishing-interfacial-tension techniques are cheaper and easier to run, but these methods are unable to capture different miscibility mechanisms fully. In the case study presented in the complete paper, the authors present a highly efficient microfluidic platform to measure, in a faster and easier manner, high-quality MMP data of CO2 with various impurities significantly.

Introduction

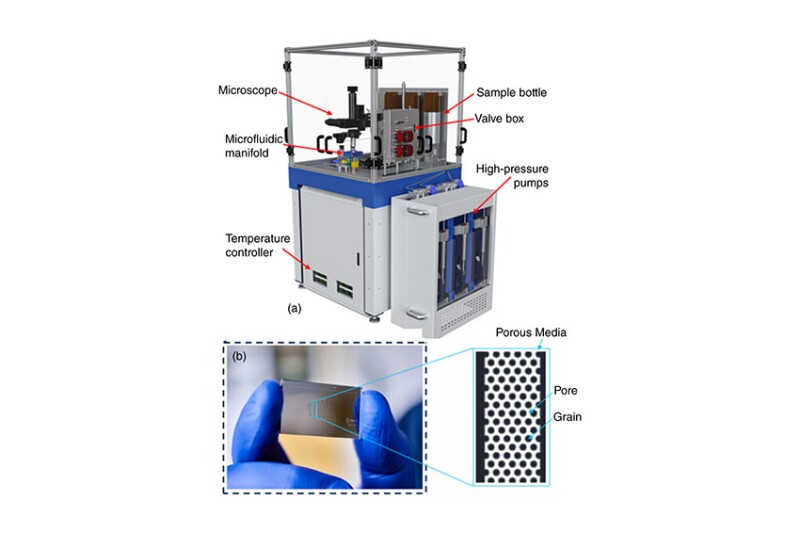

Conducting miscibility tests at high pressure or high temperature with live oil samples and real gas mixtures requires a platform capable of handling complex fluid systems at reservoir conditions.