Sponsored Content

-

SponsoredAs HPHT wells push equipment to the edge of material limits, operators are turning to advanced thermoplastics and sealed electrical assemblies to maintain system integrity. From ESP insulation to BOP control systems, the right component design can prevent failures, lower intervention costs, and extend equipment life in the harshest offshore environments.

-

SponsoredIn oil and gas operations, every decision counts. For more than 2 decades, SiteCom has been the trusted digital backbone for well operations worldwide, driving insight, collaboration, and efficiency.

-

SponsoredAdvance your career with the new Pipeline Engineering Program at the Technical University of Leoben, a 5-month course combining on-campus and online learning, integrating industry expertise, engineering practice, and future-ready skills for professionals in oil, gas, and emerging energy systems.

-

SponsoredSince 1997, intelligent completions have transformed reservoir management, but adoption remains limited due to perceived complexity. The industry reached a pivotal moment with the development of next-generation technologies that address longstanding challenges and offer simpler operation solutions.

-

SponsoredKongsberg Digital’s mobile companion to the SiteCom platform is designed to keep wellsite insight close at hand, wherever the job takes you.

-

SponsoredAltitude Energy Partners optimized drilling efficiency by minimizing dysfunctions and protecting downhole components. Their directional drilling team ensured consistent curves and laterals through precise BHA design, modeling, and trajectory control—reducing nonproductive time and drilling costs, and achieving a 100% improvement in efficiency by pad completion.

-

SponsoredThe Wyoming Gas Injection Initiative (WGII) makes available $22 million of matching funds from the State of Wyoming to implement, in close collaboration with oil and gas operators and Dow, multiple field pilot projects in the State of Wyoming. The Initiative will fund projects over a 3- to 5-year period to support developments with significant potential to enhance wel…

-

SponsoredWhat are we, in the upstream oilfield service companies, doing about it? The Middle East upstream oil and gas industry is shifting its focus to unconventional and tight-gas resource development.

-

SponsoredHow are upstream operators setting their geoscience teams up for success? Which data management capabilities are most important? And which geo data challenges are outstanding? These questions and others are answered in a report by the industry analysts IDC, based on a survey of industry participants.

-

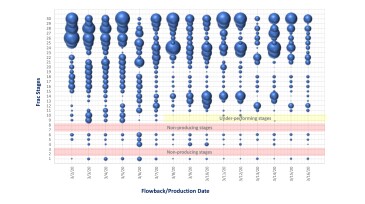

SponsoredThe data that comes with mapping flow behavior at the stage level of unconventional wells was once accessible only through the installation of costly and intrusive diagnostic methodologies like fiber optic or running production logging. New-generation FloTrac ultrahigh-resolution nanoparticle tracer technology with subatomic spectroscopic measurement techniques now de…

-

SponsoredImprove modeling accuracy and reduce the risk of unplanned downtime. By eliminating the need for multiple applications, complete more accurate comprehensive pressure safety studies faster.

-

SponsoredThe Wyoming Gas Injection Initiative (WGII) makes available $22 million of matching funds from the State of Wyoming to implement, in close collaboration with oil and gas operators and Dow, multiple field pilot projects in the State of Wyoming. The Initiative will fund projects over a 3- to 5-year period to support developments with significant potential to enhance wel…

-

SponsoredQuickly identifing the right strategies for a well or pad can overcome operational challenges. These cost-effective and easy-to-use solutions help operators achieve improved production rates with less manpower.

-

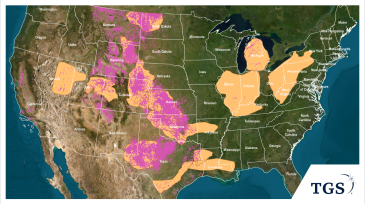

SponsoredIn a partnership with the American Institute of Formation Evaluation, TGS is now the only US data vendor offering report-sourced drillstem tests, available through TGS Well Data Analytics.

-

SponsoredThis Q&A highlights the benefits of AI and ML to automate work flows and analyze data at a much faster rate—within minutes. These capabilities deliver a fit-for-basin approach designed specifically for US-centric work flows.

-

SponsoredImprove modeling accuracy and reduce the risk of unplanned downtime. By eliminating the need for multiple applications, get more accurate and comprehensive pressure safety studies faster.