blowout preventer

-

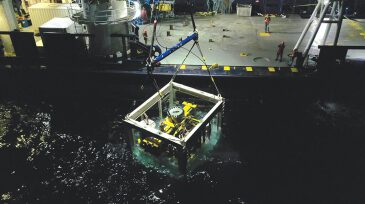

In 2013, a technology-development project began that digitized, automated, and applied analytics to blowout preventer pressure testing. As a result of the deployment of automated BOP testing, significant improvements have been achieved in process safety, personal safety, and rig-time savings.

-

A lot about the blowout preventers used for offshore drilling has changed since Macondo in 2010, but the essentials remain. This evolution serves as a case study on why some oilfield technology is hard to change.

-

This paper describes the mobilization of a snubbing unit and blowout preventer (BOP) stack in the Middle East that enabled a well with an underground blowout and surface broaching to be brought under control within a short time.

-

The new well control rule is evidence that memories of the Macondo blowout remain a powerful force for caution. Despite the rhetoric on both sides of this hot-button issue suggesting big changes, the final changes were incremental.

-

The biggest drilling company appears interested in becoming the most innovative. It is testing inventions ranging from a blowout preventer that is not hydraulically powered to power systems designed like a hybrid car.

-

The Bureau of Safety and Environmental Enforcement says its final well-control rule removes unnecessary regulatory burdens to responsible offshore development while maintaining safety and environmental protection.

-

New long-term contracts between offshore drillers and equipment makers reduce downtime and risks associated with key components, from blowout preventers to risers.

-

Well control is built around huge steel machines, but the future of the business is digital. Data have become a critical asset as operators and service companies work to increase the safety and reliability of their products and operations.

-

A new blowout preventer design shows potential for delivering much greater shearing power than current BOPs. The design is simpler and more efficient than current BOPs.

-

After the 2010 subsea blowout of the Macondo well that resulted in 11 deaths and the worst oil spill in US history, early kick detection technology found itself at the top of the wish list for regulators and offshore companies seeking to avoid similar accidents.