bottomhole assembly

-

The authors discuss a study based on twistoffs experienced with bottomhole assembly components during drilling operations and provide recommendations for reduction or elimination of these incidents.

-

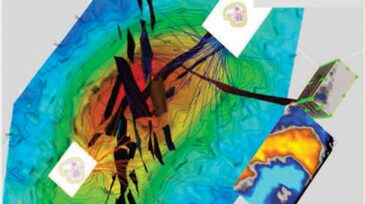

This paper highlights the potential of machine learning to be used as a tool in assisting the drilling engineer in bit selection through data insights previously overlooked.

-

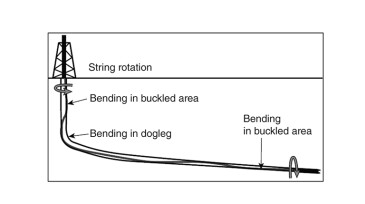

The authors write that simple changes in drillstring design can lead to huge savings in a climate that demands continual reductions in well-delivery time and well costs.

-

Anomalies in heart function can be diagnosed in real time by measuring an electrical signal. Petroleum engineers have adapted the concept to diagnose anomalous drilling conditions in real time using a shock signature recorded downhole.

-

The complete paper presents a methodology designed for optimally matching drill bits, mud motors, and bottomhole-assembly components for reduced failure risks and improved drilling performance.

-

The complete paper discusses a new performance-evaluation methodology that combines bottomhole assembly (BHA) modeling with field data.

-

This paper explores the nature of the vibrational dysfunction known as BHA chatter. A field-proven frequency-domain model illustrates the cause of the dysfunction, its rotary-speed dependence, and mitigation methods and results.

-

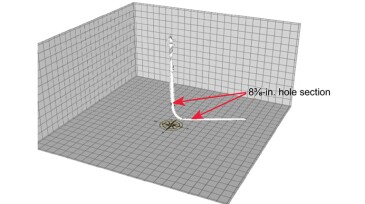

The complete paper describes an offshore artificial island project northwest of Abu Dhabi in which drilling limits were extended continually by adopting new technologies and practices in an extended-reach-drilling (ERD) campaign.

-

This paper describes the analysis of sidetracks drilled in an open hole by an annular ledge formation method with a downhole motor in multilateral wells.

-

This paper shows how high-frequency, real-time drilling data from wired drillpipe has helped optimization of drilling performance and achievement of additional improvements in the New Mexico Delaware Basin.