digital twins

-

Developing the facility of the future is a technological and infrastructural challenge, but the people behind the technology play just as critical of a role in actualizing complex, innovative asset designs. How will future facilities affect the way companies operate?

-

As part of the $11-million deal, Kongsberg will establish a dynamic virtual representation of the plant, which serves as a gas processing and export hub for the Shell-operated Ormen Lange in the Norwegian North Sea.

-

The two companies have entered into a partnership to develop the oil and gas industry’s first methodology for qualifying the integrity of digital twin technology.

-

The service company and independent verifier are aiming to develop a methodology for qualifying the integrity of digital twins, which they say will help level the industry’s varying technical definitions of, and expectations towards, the technology.

-

The company has proposed the Probabilistic Digital Twin to close the gap between digital twins—used increasingly by operators to manage the performance of their assets—and risk analysis still largely conducted manually before assets enter service.

-

Photogrammetry—stitching together images to create photorealistic 3D models—can be part of a larger industrial digitalization strategy that aims to liberate data from its silos, connect it to other relevant information, and make it available to the workers who need it.

-

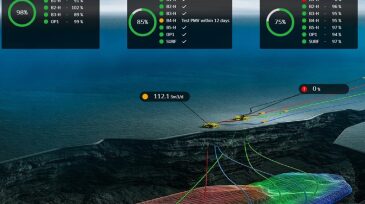

An increasingly buzzy term tossed around at industry events, “digital twin” is leveraging data analytics, machine learning, and artificial intelligence to improve efficiencies from design to decommissioning.

-

The latest example of the offshore sector's march toward automated wellbore construction will take shape later this year in the North Sea.

-

Remote condition monitoring of offshore platform equipment tracks performance data, watching for deviations from baseline benchmarks. Unexpected variances can be investigated and serviced by technicians dispatched to target the root causes—an approach called condition-based maintenance.

-

What do 60,000 sensors on 1,200 pieces of equipment add up to? Hopefully, hundreds of millions of dollars in savings.