drill cuttings

-

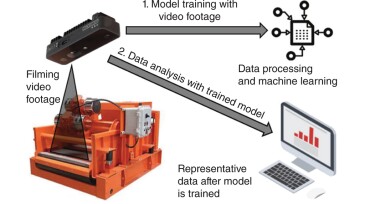

This paper describes an experimentation trial deploying and operating a computer-vision system on a deepwater rig to measure drilled cuttings in real time using a remotely monitored camera system.

-

New strides in computer vision, well controls indicators, and BOP alignment were showcased at the recent Offshore Technology Conference.

-

From optimizing drilling performance to enhancing worker safety, computer vision can change how the industry works.

-

This paper proposes a holistic, automatic, and real-time characterization of cuttings/cavings, including their volume, size distribution, and shape/morphology, while integrating 3D data with high-resolution images to pursue this objective for use in the real-time assessment of hole cleaning sufficiency and wellbore stability and, consequently, for the prediction, prev…

-

The authors of this paper describe a project aimed at automating the task of cuttings descriptions with machine-learning and artificial-intelligence techniques, in terms of both lithology identification and quantitative estimation of lithology abundances.

-

The authors of this paper describe a project that demonstrated the feasibility of using deep-learning and machine-learning approaches to introduce camera-based solids monitoring to the drilling industry.

-

This paper presents the challenges and results of performing offshore drilling-waste management in a highly environmentally sensitive marine environment and UNESCO World Biosphere Reserve offshore Abu Dhabi. The solution required both thermal-treatment technology and cuttings-reinjection technology and became the world’s first single-source operation for this equipmen…

-

Many countries allow controlled discharge of drill cuttings to the marine environment, provided that operators comply with regulations designed to address potential environmental impacts. A new document released by the International Association of Oil and Gas Producers provides information on the potential environmental and nonwater-quality effects of controlled drill…

-

Safe and green innovations for handling hydrocarbon-contaminated cuttings are of great interest for offshore platforms. This paper describes a bulk transfer system that improves the safety of handling cuttings offshore and provides an environmentally acceptable approach to cuttings management.

-

A company known for being a pioneer in methods built on imaging ultratight rock at the core level has built a business testing drilling cuttings to help identify productive, fracturable rock to help operators design better completions.

Page 1 of 2