EOR/IOR

-

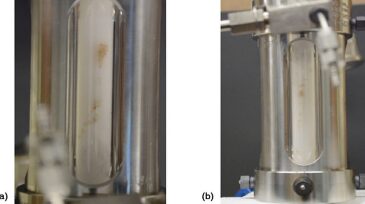

High-concentration polymer flooding can improve oil-displacement efficiency but separation of oil/water mixture becomes more difficult because of emulsification. In this work, a case history of dehydration technology for HCPF production and lab investigation of emulsion behaviors are reviewed.

-

Saudi Aramco saw a jump in production for a type of EOR that often takes years to see full benefits.

-

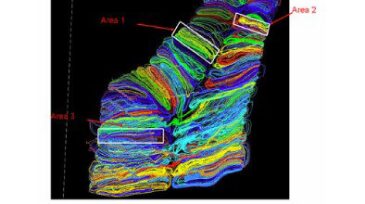

Carbon dioxide (CO2)/water foams are of interest for mobility control in CO2 enhanced oil recovery (EOR) and as energized fracture fluids or as hybrid processes that combine aspects of both processes.

-

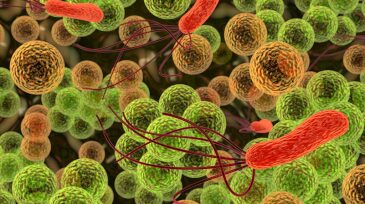

This article describes how the use of a biological EOR technique that applied produced water for reservoir flooding in a mature field led to rapid and substantial increases in oil production.

-

This study provides technical analysis of the viability of enhanced-oil-recovery (EOR) processes; the results indicate the potential for significant improvement in recovery efficiency over continued waterflooding.

-

The label unconventional oil and gas stubbornly hangs on because these formations cannot be understood using the rules of conventional petroleum engineering.

-

The authors discuss the results of a pilot project to capture post-combustion CO2 for purposes of EOR.

-

A new type of organically modified silica glass that can remove a wide variety of oils and contaminants from produced and flowback water is showing promising results as it undergoes field trials.

-

The lifespan of a huge, old oil field in Oklahoma is now linked to a fertilizer plant 68 miles away. Chaparral Energy is capturing 45 million ft3/D of carbon dioxide (CO2) that had previously been vented into the atmosphere in Coffeyville, Kansas, compressing it, and sending it via a pipeline.

-

Changing the salinity of injection water could make the difference in getting more out of existing wells.