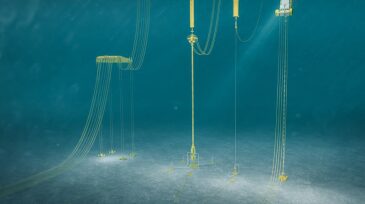

risers

-

This paper reviews best practices and learnings from floating-production-unit transportation and installation, hookup, and commissioning and discusses subsea flowlines, export pipelines, and subsea-equipment installations.

-

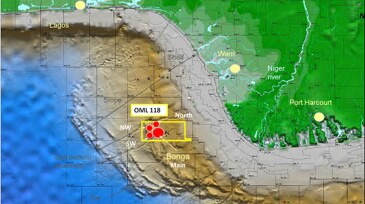

This paper discusses the journey of the Bonga North project, highlighting challenges and resolution strategies in a constantly changing deepwater environment.

-

The second phase of the project will analyze data gathered in Phase 1, with the goal of improving riser, wellhead, and conductor fatigue estimates.

-

Contractor, operators will work to bring thermoplastic composite pipe (TCP) flowline and riser technology to market.

-

The honorees will be recognized later this year at the OTC Distinguished Achievement Awards Luncheon.

-

High-strength, sour-service-grade carbon steel has been developed with outer diameter up to 23 in. and wall thickness up to 2.5 in. using a robust manufacturing process.

-

The project will create a foundation for further development of a thermoplastic composite pipe jumper technology for risers in permanent HP/HT subsea applications.

-

The data-driven maintenance program incorporates riser condition, usage, and fatigue analysis with a risk-based inspection process.

-

Nonmetallic, thermoplastic composite pipe (TCP) technology can now be found in every oil and gas region globally and can operate at pressures of up to 12,500 psi, and in water depths as low as 3000 m. The focus is now on developing and deploying TCP risers for extreme environments.

-

As part of an effort to evaluate existing riser systems, an operator launched an inspection and testing program to investigate risers retrieved following well abandonment after a service life of nearly 10 years in the Gulf of Mexico.

Page 1 of 3