water reuse/recycling

-

Frac water disinfection experts become De Nora service arm in the unconventional oil and gas market.

-

Water management for upstream will transform over the next few years. In many cases, more-effective water management will only be possible with water infrastructure.

-

Secretary of the Interior Ryan Zinke on 12 May announced that the Bureau of Reclamation awarded USD 23,619,391 to communities in seven states for planning, designing, and constructing water recycling and reuse projects.

-

Newfield Exploration broke ground on a water recycling facility in the Anadarko Basin in Oklahoma.

-

Sourcing water for large multifracture stimulations in west Texas is a well-known constraint on oil and gas activities in the area. A 6-month pilot operation demonstrated that produced-water reuse is technically feasible and can be a cost-effective solution.

-

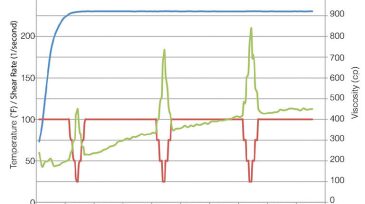

This paper summarizes the benefits of using a bipolymer crosslinking system in environments where water quality cannot be guaranteed. It also demonstrates the yielded cost savings per well that are achievable when reusing 100% produced or flowback water for hydraulic fracturing.

-

This paper reports the completion of a two-lateral well in the Williston basin where produced water (PW), filtered but otherwise untreated, was used throughout the slickwater and crosslinked components of approximately 60 hydraulic-fracturing stages.

-

This paper details the experience of using new stabilized crosslinked-fracturing-fluid systems in the Permian Basin using borated produced water.

-

Market dynamics and costs drive the search for solutions. In California, where water is needed, producers are finding potential for reuse of waste water.

-

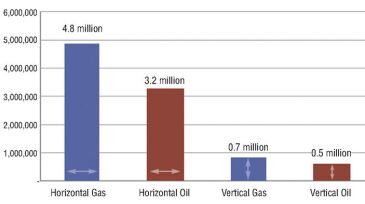

Companies are deploying a variety of technologies to reduce the water needs of hydraulic fracturing. Where are these new facilities with these new technologies, and how will they help operators solve the problem of finding water to use?