The Industrialization and Energy Service Company (TAQA) is a leading energy enabler with headquarters in Saudi Arabia and operates globally in over 20 countries. TAQA is at the forefront of integrating innovative and sustainable materials into oil and gas well construction. This initiative aligns with TAQA’s commitment to energy security while simultaneously safeguarding the environment for future generations.

Environmental Sustainability and Energy Security

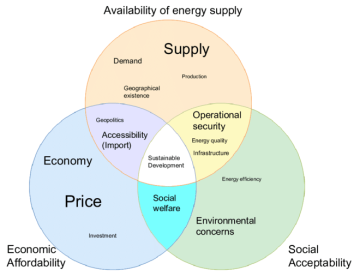

As shown in Fig. 1, sustainable development is at the heart of energy supply. The growing need to replace traditional materials in oil and gas well construction with sustainable alternatives is increasingly evident. TAQA, in its cementing operations, recognized the crucial role of these materials in reducing its carbon emissions. Conventional materials like standard cement and chemical additives pose environmental risks, including high carbon emissions and potential contamination. The push for sustainable alternatives is driven by the industry's commitment to environmental responsibility and regulatory pressures to reduce greenhouse gases (Smith & Brown, 2020). Promising solutions include bio-based additives, recycled byproducts, and low-carbon cement alternatives.

These sustainable materials not only reduce environmental impact but also improve the performance and durability of well structures, leading to better asset management and control. For example, geopolymer cement, which uses industrial waste, can significantly cut CO₂ emissions compared to traditional Portland cement.

Adopting these alternatives is vital for aligning the oil and gas industry with global sustainability goals while maintaining operational efficiency and safety. Continued research and development will be essential for overcoming challenges and promoting the widespread use of these materials in well construction.

TAQA’s Leadership in Sustainable Well Construction

Transitioning from conventional materials in the oil and gas industry is a formidable challenge, as it requires countless hours of dedication and research to ensure the technical requirements align with environmental optimization. However, TAQA’s commitment to environmental stewardship drives us to tackle this challenge head-on. At TAQA, we understand the urgency of protecting our planet, and this understanding fuels our dedication to investing in research and development to discover and implement sustainable/innovative materials that can revolutionize the industry.

TAQA’s focus on sustainability goes far beyond regulatory compliance or gaining a competitive edge—it is about making a lasting and positive impact on the environment for future generations. The successful deployment of various sustainable products in TAQA’s well-construction projects has already demonstrated significant environmental benefits and operational excellence. These achievements are not merely milestones; they are affirmations that our goals are being realized. For instance, the use of alternative, more sustainable, materials has led to a reduction in the carbon emissions associated with cementing operations in addition to improving the performance efficiency of the operations.

We are motivated to continue advancing, knowing that each step brings us closer to a future where energy security and environmental sustainability coexist harmoniously. TAQA’s journey is a testament to our belief that sustainable practices are not only possible but essential for the future of the energy industry.

Exploring TAQA’s Sustainable Well Construction Products

TAQA’s cementing product portfolio includes a medium-temperature retarder (MTR) formulated with 100% sustainably sourced materials, offering superior performance compared to conventional synthetic alternatives. Since its introduction, this retarder has been successfully used in a series of wells across various regions, receiving excellent post-job reviews and well control indices.

TAQA also offers a range of environmentally friendly cement expansion additives tailored to specific applications, whether pre-expansion, in-situ expansion during placement, or post-expansion after cementing.

Additionally, TAQA’s use of 100% sustainable lost circulation material (LCM) has revolutionized drilling fluids technology in the oil and gas industry. This product as shown in Fig.2, formulated from 100% biodegradable waste materials, has proven to be a game changer that ensures reliable well control throughout drilling operations. It offers dependable compatibility with both drilling mud and cement designs, leading to improved mud removal and efficient cement placement. The outstanding bond log results from wells where this product was deployed reveal superior casing-to-casing and casing-to-formation bonds.

Lastly, TAQA has explored alternative uses for its swellable materials as shown in Fig. 3, ensuring 100% utilization of manufactured products and eliminating residual waste. This product is used for loss control, water control, and zonal isolation. It can easily be pumped into a target zone and swelling to create a permanent high-pressure seal. Particle sizes vary and are selected based on the zone size and application. Applied field cycle pressures have reached up to 11,200 psi without leaks, and the ability to bullhead the product in place eliminates the need for rigs or complex interventions, significantly reducing the CO₂ footprint.

Conclusion

TAQA’s pioneering efforts in integrating sustainable materials into oil and gas well construction represent a significant step forward in the industry’s journey toward environmental responsibility. By embracing innovative and eco-friendly solutions, TAQA is not only reducing the environmental impact of its operations, but also setting a new standard for operational excellence and energy security. The company’s commitment to sustainability is evident in the successful deployment of cutting-edge products that enhance well performance while minimizing carbon emissions and waste. As the energy industry continues to evolve, TAQA’s leadership in sustainable practices will play a crucial role in shaping a future where environmental stewardship and energy development are inextricably linked. Lastly, through continued innovation and dedication, TAQA is helping to ensure that the industry can meet the energy demands of today while safeguarding the planet for future generations.

References

- Smith, J., & Brown, T. (2020). Sustainable Materials in Oil and Gas Well Construction: A Review. Journal of Petroleum Science and Engineering, 188, 106977. doi:10.1016/j.petrol.2020.106977

- Ohochukwu, C., Mathew, S., and Liang, Z. (2024, February). Development of a New Retarder Recipe Containing Boric Acid, Which Exhibits Excellent Mechanical Properties Suited for the Mid Temperature Range (MTR) in Oil and Gas Well Cementing Operations. International Petroleum Technology Conference.