For reasons deep below the surface and right atop it, the North American shale sector was due for a period of turbulence and contraction. Then came two unforeseen accelerants: a global pandemic and a costly price war—the combined forces of which sent oil prices down by a record 65% during the first quarter of the year.

The double blow to the US shale sector has meant that in all likelihood, hydraulic fracturing activity in North America has peaked. Going forward, there will be fewer players and less production. Some estimates project that by the end of the year, the hydraulic fracturing market will be just 50% of what it was before the latest crash.

Just as likely though is that this disruptive corner of the oil and gas industry will persist. Shale resources in the US remain vast. Even more untapped resources are found elsewhere. But first, costs will have to be cut and a lower-cost business structure will be needed to match this second round of “lower for longer.”

As rigs drill faster with squeezed day rates, completions operations represent as much as 70% of the total cost it takes to bring in a horizontal well. Therefore, it could be argued the hydraulic fracturing side of the business has the most to benefit from adopting new technologies in the sector’s effort to cross the chasm.

Despite the obvious challenges that come with a shrinking market, a set of emerging technologies are profiled in this article to highlight how the shale sector can get rid of its hidden inefficiencies and reduce the time it takes to hydraulically fracture a multiwell pad. This is a process that takes anywhere from a few weeks to more than a month. Through innovation, these spans can be trimmed and along with that, the capital overhead required to generate each new shale well.

Deep Well Services: A Quicker Drill Out

The Problem. To extend well economics, shale producers have extended the length of modern well designs to 10,000 ft and far beyond. But most traditional coiled-tubing systems—used to mill out plugs between fracturing stages—are not able to reach such extreme lengths, sometimes requiring the use of conventional snubbing units that take days to rig up.

The Innovation. The Hydraulic Completion Unit (HCU) was developed by Deep Well Services (DWS) to simplify and speed up the mill-out process of these high-pressure, long lateral wells.

Since starting up in 2008, DWS has carved out a niche by borrowing technology from another niche—the snubbing sector. Snubbing is a workover process that involves pushing pipe and tools down a highly pressurized well. Removing frac plugs during the completions process is not that different, so DWS combined its own customized systems to invent a snubbing unit that would be efficient enough to compete with coiled tubing for work on horizontal wells.

Whenever operators are looking to push the envelope on what defines a long lateral, DWS is usually on that job. “All the longest wells in the lower 48 ever drilled, we’ve drilled them out,” said Mark Marmo, a cofounder and chief executive officer of DWS, referring to the use of the HCU to drill, or mill out, frac plugs.

How It Speeds the Completion. Atop the HCU stack, crews literally stand with the full energy of an active horizontal well at their feet. The idea is to push back on this energy, or “snub force,” with a drill bit on a bottomhole assembly (BHA) that is 16 ft long but less than 4 in. wide.

“It’s a massive amount of horsepower in such a condensed package—and in over 95% of the cases, we’re drilling these plugs out with one bit on one trip,” which includes a record-breaking 21,000-ft lateral drilled in the Appalachian Basin, Matt Tourigny, vice president of marketing and innovation at DWS, said.

Highlighting the speed of the process, he added that the HCU drills out the plugs “in less time than there are plugs,” meaning that on a job with 120 frac plugs, the time to remove them would be around 110 hours. He said it would be hard for a coiled-tubing unit to match this time in extended laterals, in part because coiled tubing must be “swept” by pulling back to the heel or vertical occasionally and may also need BHA tools such as agitators to be added, neither of which are required for the new snubbing approach.

Last year, the small company based out of the Pittsburgh, Pennsylvania, area completed 827 wells for more than 40 operators. Since it started up, DWS reports that its innovation has captured the majority of the plug drill-out market in the Marcellus and Utica Shales involving wells longer than 8,000 ft—largely displacing the use of coiled tubing for the segment.

Among the system’s key components is an elastomer seal that holds back pressures up to 15,000 psi. An in-house-designed slip interlock system prevents crews from dropping or launching pipe—a problem that has given the snubbing business a “blackeye,” Tourigny said.

Pushing everything downhole is a hydraulically activated “jack plate” that repeats its up-and-down process as many times as is needed to hit the desired depth. The work string—designed to withstand highly deviated wells and severe doglegs—is then rotated to drill out frac plugs.

The most powerful of the 10 units DWS has built so far is capable of applying downhole torque of up to 10,000 lbs with a rotary table that can operate at 120 rpm. The HCU can also pull 300,000 lbs back out of the well, virtually eliminating the concern that the pipe will get stuck while enabling it to be used for fishing.

In addition to drilling out the plugs after a horizontal well has been stimulated, and just like its older hydraulic workover cousins, the hardware amounts to a multipurpose well-intervention system that is used to:

- Mill out stuck plugs

- Clean out sand (e.g., screenout remediation)

- Fish for coiled tubing, wireline, or lost perforating guns

- Run production tubing coupled with capillary lines, gas lift mandrels, perforating guns, and packers

Reflecting the growing importance of real-time data and analytics in the completion space, DWS uses sensors on its rigs to capture live data. “It’s always been on the drilling side and in the coil side, but no one really sat back and said, ‘OK, let’s design that for a snubbing unit,’” Tourigny said.

He noted that this historical blind spot yields valuable insights on job time and well-cleanout performance if the data are collected in the first place. Many well designs in a given area are similar and deal with roughly similar pressures, allowing the operators to set benchmarks on the entire operation. When the analytics show a unit is falling below the benchmarks, Tourigny said “it’s an instant call to the rig.”

Corva: A Speedier Swap Over

The Problem. The hydraulic fracturing fleet of the modern era has not been so modern when it comes to data acquisition or making much use of the data. With few exceptions, this has applied to just about every mission-critical piece of on-site equipment.

The lack of data quality or real-time analytics on surface operations leaves office staff with a limited view of the true state of field operations. This has been considered a significant driver of invisible lost time—an issue that has received far more attention in recent years in the drilling sector.

The Innovation. Corva is known mostly for its success with an analytics platform that has seen rapid adoption in the shale drilling sector in the US. Less than a year ago, the Houston-based startup launched a completions version of its platform which is active on 20 fracturing fleets as of April. “We started out in drilling, but our goal is to take that higher workflow and deliver it to completions,” Ryan Dawson, chief executive and founder of Corva, said.

The system and its 35 apps are used to monitor and benchmark a number of key parameters during a stimulation, including time to full rate, initial shut-in pressures, wireline activity, and even plug mill outs. Critically, this datastream is available to everyone on the worksite as well as in the office. Corva said its operator clients are finding the most value in tracking “frac swap overs.”

How It Speeds the Completion. Corva uses its own field staff to install data-acquisition units inside each of the fracturing data vans on a completions site—roughly the same hardware it uses on rigs. Data from sensors on different completion systems is streamed from the unit into Corva’s visualization platform. From there, equipment state can be measured and acted on in real time—again, much as remote drilling operations have functioned for the past few years.

The amount of time it takes crews to alternate fracturing one well to the next, or a swap over, represents some of the lowest-hanging fruit for the platform.

During simultaneous operations, a completion crew needs to be in full sync to maximize the efficiency gains. But if a wireline run is behind schedule, it could mean that pressure-pumping units are running idle as they wait to pump the next stage.

Dawson said his company has seen that swap-over times of an hour are not uncommon. But there’s another reason for all the interest over this metric. “No one had ever looked at the data because it didn’t exist,” he emphasized, adding that it was simply never recorded or if it was, never shared with the customer.

Houston-based Corva’s system shows that watching just a few key factors can deliver big results. Using simple alerts and color-coding schemes, crews can see if a wireline was running too fast, which is known to cause downhole issues and wear and tear. The screen also shows crews which stages missed their time targets.

A recent study for a client in Oklahoma showed that the wireline crews were not consistent in these running speeds, prompting an easy correction that saved day-rate dollars.

Dawson said that over the course of just 2 weeks, through benchmarking and effecting improvements, completions crews tended to drop 20 to 25 minutes in their well transition times. He added that this generates more than $200,000 savings per pad. “It’s crazy, but those little things are what move the needle.”

Notably, Dawson said the introduction of the real-time monitoring technology has encountered more cultural issues with fracturing crews than the company’s breadwinning rig-monitoring system.

“They never had big brother watching over their shoulder,” as opposed to drilling crews which have been stalked by company men and operators’ data analytics teams for years. “But, it turns out that you turn it on and instantly they are performing better,” Dawson said.

DMS Technologies: Zippier Than a Zipper

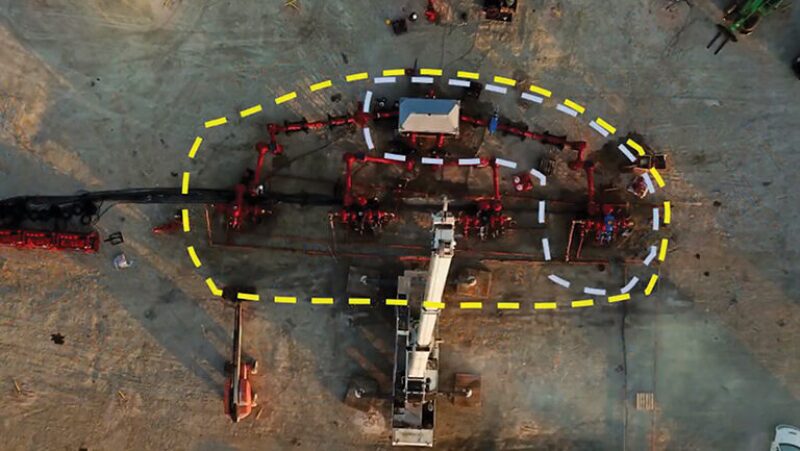

The Problem. Over the past several years, the rise of the zipper fracture technique, enabled by a manifold of the same name, has represented one of the shale sector’s biggest efficiency gains—and is one of its most unsung inventions.

Without zipper manifolds, each well on a multiwell pad would have to be hydraulically fractured one at a time. With them, service companies can stimulate one well while running wireline down another, i.e., simultaneous operations, and then alternate back and forth to maximize the use of the on-site pumping equipment. Despite the clear upside it brings to well economics, the zipper manifold is an ad hoc system that introduces its own inefficiencies.

- A zipper manifold is directly connected to each wellhead with injection and isolation controlled by a series of valves. Because of this, a safety-driven “red zone” or “critical zone” is defined as the area surrounding the manifold, all the pressure-control iron, and the wellheads themselves. A large-enough restricted area may limit simultaneous operations during the treatment.

- The manifold’s valves controlling the flow of highly pressurized fluids require lubrication after every few stages. Some of the valves can hold up to 20 lbs of grease.

- The manifold does not follow the rest of the fracturing spread. Typically, zipper manifolds are broken down, inspected, and repaired, if necessary, after each pad treatment. Repairs can be expensive and time consuming, constraining asset utilization.

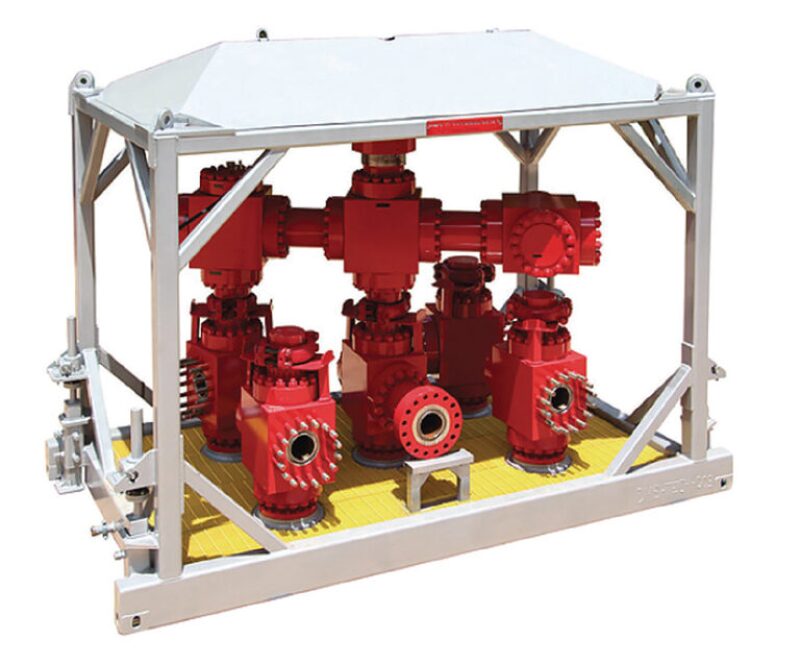

The Innovation. The Quick Connect System (QCS) was introduced by Houston-based DMS Technologies to the shale sector just over 2 years ago to replace the zipper manifold. The QCS costs about the same as a zipper manifold, the company said, and so far it has been used on more than 8,000 stages in major US shale basins including the Permian Basin, along with the Eagle Ford and Bakken shales.

The system has no valves, so no greasing, and it swivels to connect into each wellhead individually. This means that unlike a zipper manifold, only one line and wellhead are under pressure at any given time. This creates a smaller red zone and allows simultaneous operations on the other wells on the completion pad. Additionally, since there are no valves, the possibility of opening or closing the wrong valve is eliminated.

The startup’s founders are completions operations specialists who launched the company to design a new generation of pressure-control components. John Jameson, one of the cofounders, said the idea was the result of various studies into operational improvements.

“It’s nothing new,” said Jameson of the industry’s desire to become more efficient. “But there’s just not enough people looking at it from a completions perspective.”

How It Speeds the Completion. The QCS is rated for 15,000 psi and features an articulating arm in the center of the unit that turns 360° on ball bearings. Using a counterweight, only two people are required to unlock it and gently swing it into one of four discharge sections that are rigged up to each wellhead. The lack of valves, compared to the 10–12 usually found on a zipper manifold, reduces the number of failure and maintenance points. The units also use no hammer union connections, compared to the 200–250 required for a typical zipper manifold.

With its moving arm and simplistic design, DMS is saving time not by tracking swap overs using software, but by making them easier to do. The company said the average time it takes fracturing crews to close and open valves on a typical zipper manifold from one well to the next is about 20 minutes. The transition time could be much longer if greasing is required. In contrast, DMS reports an average transition time that is under 10 minutes.

So how often is the transition time a meaningful metric for completions crews?

The time spent between injecting one wellhead and swapping to the next one has not always been considered a big problem. Other factors, such as pump downtime or wireline operations, have created larger bottlenecks. But service companies have become more efficient in recent years thanks to new processes and technology.

Jameson points out that improvements in those areas have now exposed the importance of trimming the 10–20 minutes it takes a crew to alternate between wells using a zipper manifold. He added that the length of the transition can depend on the condition of the equipment. If the manifold is newer and well maintained, the transition time could be below 20 minutes.

“But a lot of times what people have to do every two to four stages is a complete shutdown to allow the zipper manifold provider to grease the valves; that could be an hour to an hour-and-a-half-long process,” he said. On the high end, DMS estimates that eliminating just the greasing can shave off more than 2 days in a typical multiwell completion.