Artificial lift

This paper presents a robust workflow to identify optimization opportunities in gas lift wells through real-time data analysis and a surveillance-by-exception methodology.

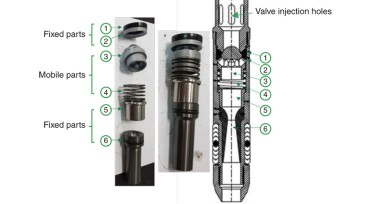

To overcome operational constraints tied to ball-and-seat valves, an operator tested a spring-loaded alternative downhole.

Field results highlight how rethinking tubing-anchor-catcher design can reduce gas interference and support late-life production.

-

What is the one thing you can do that will provide the greatest benefit to your artificial lift operations? For me, the answer to that question is simple: focus on surveillance. Surveillance is the foundation of any artificial lift optimization program. Effective surveillance practices allow you to keep track of how your system is performing against predefined targets…

-

The paper describes a project automating the progressing-cavity-pump well-modeling process wherein models are built and sustained automatically in a well-management system for all active PCP wells.

-

SponsoredEach well drilled, stimulated, and completed represents a significant investment in time, resources, and expenses. From artificial lift system design to maintenance scheduling, maximize your investment by ensuring optimal flow and production throughout the life cycle.

-

An experimental study of a shroud-type downhole separator for a pumped horizontal or deviated well is presented in this study.

-

Do you know how many of your organization’s wells are artificially lifted? Or, more importantly, do you know what fraction of your production volumes are dependent on artificial lift? I would wager that the percentages are higher than you would expect, and I encourage you to seek out that information and share it.

-

This paper describes a comprehensive approach to mitigate systemic failure in gas-lift valves in presalt wells.

-

This paper describes a study aiming to provide input for the well-completion-strategy design and operational parameters for a carbonate reservoir experiencing electrical-submersible-pump failures.

-

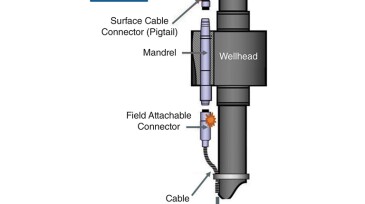

This paper describes the findings of a root-cause analysis of wellhead-penetrator failures in Canadian steam-assisted gravity-drainage operations and the mitigation measures taken.

-

This paper discusses the field implementation of a downhole chemical methodology that has positively affected overall productivity for a mature Kuwait field.

-

SponsoredRod lift failure frequency in horizontal wells drives significant operating expenses. Understanding why these failures occur leads to a solution — production optimization with automated setpoint changes, which can extend the life of this equipment and reduce downtime.