Artificial lift

This paper presents a robust workflow to identify optimization opportunities in gas lift wells through real-time data analysis and a surveillance-by-exception methodology.

To overcome operational constraints tied to ball-and-seat valves, an operator tested a spring-loaded alternative downhole.

Field results highlight how rethinking tubing-anchor-catcher design can reduce gas interference and support late-life production.

-

The authors of this paper develop a model that can predict well-risk level and provide a method to convert associated failure risk of each element in the well envelope into a tangible value.

-

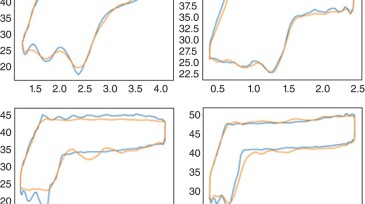

The paper presents results of single-phase and multiphase electrical-submersible-pump tests as well as operation data, lessons learned, and failure examples gathered over 10 years of operation in a highly viscous offshore oilfield.

-

Artificial lift has long been thriving in the exciting innovation zone that the electronics industry is only now approaching. Just when you think the artificial lift community knows everything, people find new ways to turn old maxims on their head. The selections this month are true paradigm-changers.

-

A major variable in the life of a progressing cavity pump is the knowledge of those choosing and operating pumps that have their quirks.

-

The electrical submersible pump market is forecast to hit $6.7 billion in 2023.

-

Petronas and Pertamina share their technical approach in implementing and optimizing artificial lift using advanced technology and their vision for the future. Their experiences in dealing with operational challenges in a mature field highlight areas for improvement and innovation.

-

This paper presents an oil well completion integrating multilaterals, intelligent completions, permanent downhole monitoring systems, electric submersible pump (ESP) and a horizontal wellhead system.

-

The authors write that the application of electrical parameters to diagnose working conditions and meter production of pumping wells is the key to the low-cost Internet-of-Things construction.

-

The authors of this paper present a method for prediction of sucker-rod-pump failure based on improved, completely connected perceptron artificial neural networks.

-

The paper assesses the feasibility of using a genetic-algorithm technique to optimize allocation of continuous gas lift injection rate in a network system of a Middle Eastern oil field.