This work describes a comprehensive approach to tackle systemic failure in gas-lift valves (GLVs) in presalt wells. Failure analyses in GLVs were performed after unexpected early failures leading to tubing/annulus communication. Understanding the root causes of this problem generates value for assets by increasing equipment life, preventing unnecessary workover, and reducing costs.

Equipment and Processes

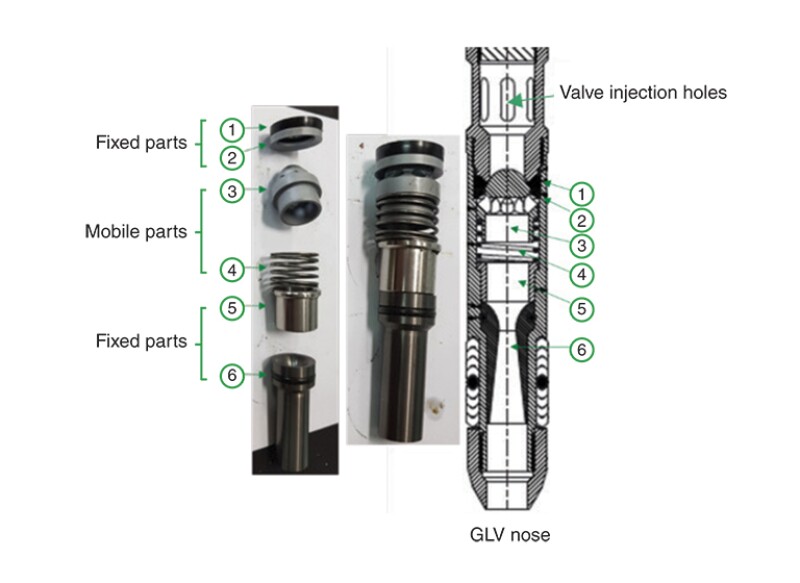

Historically, the operator used conventional orifice GLVs. The complete paper provides a history of the development of the first GLVs, with a flat seat, into a model having a seat in the venturi shape.

While GLV designs have evolved since the adoption of the venturi-shaped valves, a cause of failure was identified as blocking of the injection orifices as a result of the displacement of the venturi caused by the rupture of the elastic ring lock.

Failure analyses also brought to light important information on the flow of liquid through the valve that is common in workover operations and ramp up of production in oil wells.