Completions

Malampaya East discovery is estimated to hold 98 Bcf of gas and may help offset declines at the country’s only producing gas field.

For more than a century, LSU has shaped petroleum engineering education, but few assets showcase its impact like the PERTT Lab. With six deep test wells and rare reservoir-depth gas-injection capabilities, the facility is helping drive breakthroughs in well control, carbon-dioxide injection, and next-generation energy technologies.

This study identifies critical knowledge gaps in wellbore integrity and underscores areas that require further investigation, providing insights into how wellbores must evolve to meet the technical demands of the energy transition.

-

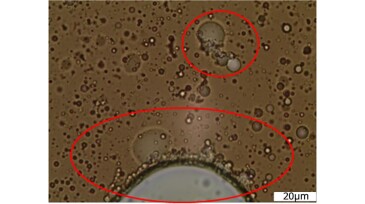

This paper details a successful pilot to improve long-term well performance using acid stimulation aided by a tailored metal oxide nanoparticle-based fluid in the Wolfcamp A formation.

-

The authors of this paper study the effect of solids particles on oil/water separators and on produced-water treatment.

-

This study highlights the strategic implementation of coiled tubing to convey perforating guns in extended-reach wells, overcoming the lockup effect through the deployment of downhole tractors and real-time monitoring tools.

-

The advances presented in the selected papers, and many others, would not be possible without improvements in our understanding of materials, how to protect coiled tubing pipes, how to get the best performance out of them under downhole conditions that are becoming every day more extreme, and how to preserve wellbore completion at the same time.

-

Fracture monitoring to optimize fluid volumes and designs remains a critical area of development. Research is ongoing with the focus on combining different monitoring technologies including tracers, fiber optics, downhole cameras, and microseismic monitoring.

-

This study emphasizes the vital need to evaluate well conditions and working-fluid compatibility with coiled tubing materials to prolong coiled tubing operational life.

-

This study introduces a detailed model to capture the physics and chemistry of acid flow in complex horizontal wells completed in carbonate formations.

-

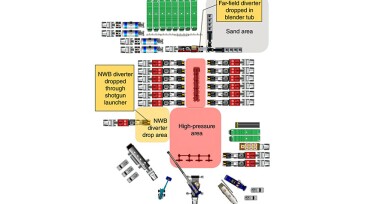

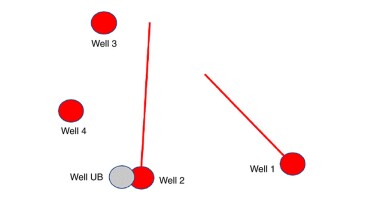

The authors of this paper describe a project in which far-field diverters were pumped to mitigate wellbore sanding and production loss in existing parent wells.

-

Engineers desperately need an alternative to acid placement through pipe, coiled tubing, or bullheading. For example, propellants have been around for years; however, their performance has not quite met the hype. Nevertheless, several case histories have been authored to suggest their efficacy; historically, some treatments have even been wildly successful.

-

This paper describes the application of an underbalanced coiled tubing technology in tight sandstones, using an integrative approach that incorporates petrophysical, geophysical, and reservoir engineering data.