Completions

Malampaya East discovery is estimated to hold 98 Bcf of gas and may help offset declines at the country’s only producing gas field.

For more than a century, LSU has shaped petroleum engineering education, but few assets showcase its impact like the PERTT Lab. With six deep test wells and rare reservoir-depth gas-injection capabilities, the facility is helping drive breakthroughs in well control, carbon-dioxide injection, and next-generation energy technologies.

Even as output hits record highs, a growing recognition of the Permian’s maturity is opening the door for new technologies to improve performance.

-

As US shale potentially stares at a production plateau, operators and service providers are turning to smarter tools to extend the life of aging plays.

-

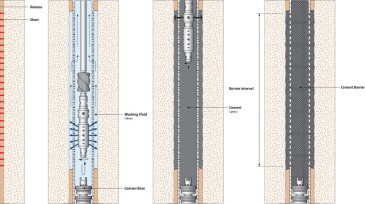

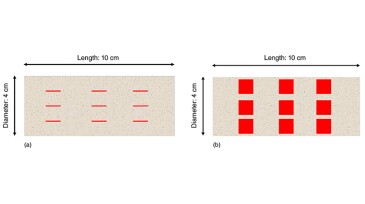

This paper presents a comprehensive literature review of perforate, wash, and cement techniques that compares new methods with traditional ones and uses field cases and computational fluid dynamics to find the most cost- and time-effective practices without sacrificing safety.

-

This paper describes the use of coiled tubing in a pilot project for carbon dioxide injection, enabling evaluation of the conversion of an existing oil field for CCS purposes and derisking storage-development uncertainties before having to cease hydrocarbon production.

-

This paper describes the first riserless coiled tubing services operation performed in a live subsea well and the associated improvements in efficiency, cost savings, and safety.

-

This paper describes a case history in the UAE in which the cleanout of scale contaminated with naturally occurring radioactive material was conducted successfully.

-

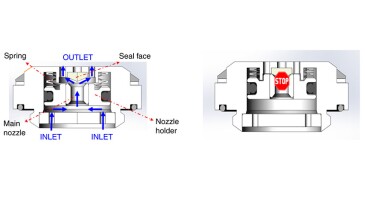

The authors of this paper describe a method of stimulating a multizone hydrocarbon-producing well wherein a tool is deployed downhole by wireline to generate acid vapor at a target depth, allowing each interval to be treated uniquely.

-

This paper extends an integrated two-scale continuum model that contemplates mass, momentum, and energy changes to study the acid-stimulation process in complex carbonate acid-stimulation systems with the development of fracture and vug networks.

-

The authors of this paper write that autonomous outflow-control devices can positively affect matrix acidizing by providing the best possible conformance.

-

New strides in computer vision, well controls indicators, and BOP alignment were showcased at the recent Offshore Technology Conference.

-

Modern completions often are equipped with downhole measurement devices that provide critical real-time data not only during the hydraulic fracturing treatment but also during the ensuing production phase.