Digital oilfield

This paper presents a multifaceted approach leveraging precise rig control, physics models, and machine-learning techniques to deliver consistently high performance in a scalable manner for sliding.

This paper proposes a novel approach toward drilling maximum-reservoir-contact wells by integrating automated drilling and geosteering software to control the downhole bottomhole assembly, thereby minimizing the need for human intervention.

This paper offers an exploration into the field applications of multiphase flowmeters (MPFMs) across global contexts and the lessons learned from implementation in a smart oil field that uses several types of MPFM.

-

Statoil’s integrated operations center on the Norwegian continental shelf is one of several initiatives operators and service companies have set in motion to improve condition monitoring and maximize production on their assets.

-

There are two ongoing trends in the industry. The first is an increasing wave of digitization. Second, piggybacking on the increased access to sensor and equipment data, analytics and artificial intelligence are on an exponential rise in the industry.

-

The complete paper provides an overview of the development of fiber-optic sensing for steam-assisted-gravity-drainage (SAGD) applications, including a review of more than 10 years of work in development and field applications in western Canada.

-

The complete paper describes a work flow in which wells and production networks in the Cheleken Block offshore Turkmenistan are automatically modeled daily with steady-state and transient tools and ultimately analyzed by the Cheleken Block Central Data Gathering System.

-

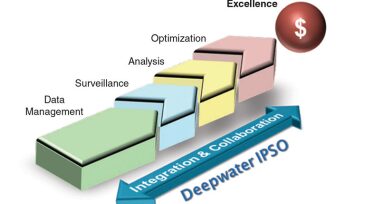

The complete paper describes some of the technical challenges faced in deepwater operations and the methodology adopted for implementing an integrated production surveillance and optimization (IPSO) system to mitigate the risks.

-

The papers selected for this issue cover advances and opportunities in well testing. They also apply reservoir fundamentals as well as sound engineering judgment, using quantity but also quality data sets from conventional and unconventional assets.

-

The adoption of emerging technologies is essential for all businesses, and even more important for well-established industries because of the perpetual threat of disruption from competitors.

-

When you think about the Internet of Things, do you think about the extensive global subsea communications network?

-

The digitalization of oil and gas facilities is becoming a new technical arena. Effective solutions can be used to convert data into information and knowledge, which can then be used to improve maintenance operations.

-

With only about 3% of data from industrial assets used for decision making or meaningful purpose, vessel, rig, and fleet owners are looking at ways to connect existing networks and assets to achieve optimized operational performance.