Drilling automation

In this study, a method was developed to analyze the effects of drilling through transitions on bit-cutting structures and construct an ideal drilling strategy using a detailed drilling model.

This paper describes a machine-learning approach to accurately flag abnormal pressure losses and identify their root causes.

This research aims to develop a fluid-advisory system that provides recommendations for optimal amounts of chemical additives needed to maintain desired fluid properties in various drilling-fluid systems.

-

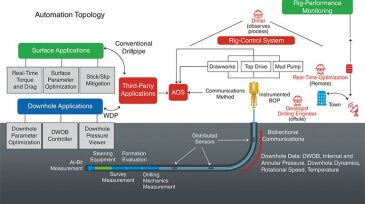

Drilling systems automation requires a digital backbone. One segment of that backbone is the interval between the drill bit and the surface. Wired pipe removes both the bandwidth and latency barriers of the available measurement-while-drilling telemetry systems.

-

In this paper, the application of a real-time T&D model is demonstrated. The process of T&D analysis was automated, and the time and cost required to run physical models offline was reduced or, in some cases, eliminated.

-

This paper presents a case history of drilling automation system pilot deployment, including the use of wired drillpipe, on an Arctic drilling operation.

-

This paper describes the progress of directional-drilling-automation systems along the cognitive functions and levels of automation as defined by the Levels of Automation Taxonomy (LOAT) hierarchy introduced by the Drilling Systems Automation Roadmap Industry Initiative.

-

Falling oil prices are the acid test of drilling efficiency. SPE Technical Director Jeff Moss of ExxonMobil talks about ways to build in lasting savings as part of this special report.

-

The latest example of the offshore sector's march toward automated wellbore construction will take shape later this year in the North Sea.

-

A contest where teams of college students design and build an automated drilling rig able to deal with hazardous obstacles in a test block, showed how a small change can be engineered to matter.

-

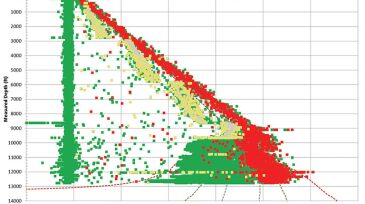

This paper proposes a metric for quantifying drilling efficiency and drilling optimization that is computed by use of a Bayesian network.

-

Signs of maturity in drilling systems automation are evident in the success stories filtering out of technical conferences and in the attraction of top university talent to an annual, international, drilling-systems-automation contest.

-

Today’s advancements in unconventional technology are worth marveling over, but there is still plenty of room for growth.