Drilling

This paper provides an account of the design, implementation, and operational insights from an enhanced geothermal system proppant stimulation targeting a volcanic, dry rock setting with an approximately 330°C bottomhole temperature.

This study evaluates the feasibility of drilling a closed-loop, unconventional geothermal system in the Pannonian Basin basement of Romania.

The paper describes a multientry multistage fracturing technology developed to enable longer laterals, increase stage counts, improve stimulation efficiencies, and derisk operations.

-

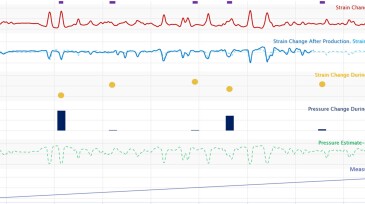

The authors of this paper describe a project in which Raleigh frequency-shift distributed strain sensing monitored during production in a far-field observation well was translated to an estimated pressure profile.

-

Typically, oil and gas producing wells are abandoned toward the end of their life cycles with reservoir pressures depleted compared with the virgin pressures. Carbon capture and storage projects, however, present different operating conditions.

-

SponsoredWith more surface facilities and infrastructure in oil and gas fields, well casing integrity is becoming an even bigger challenge. This article sheds light on the optimum way to deal with the increasing casing integrity challenges in the Middle East through field monitoring and time-lapse casing-integrity and corrosion-inspection logging.

-

The well was spudded from the new Azeri Central East platform in the giant ACG field in the Caspian Sea.

-

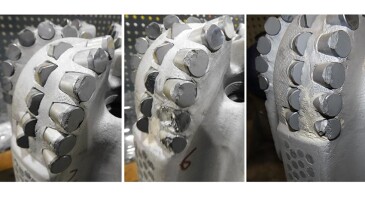

As bottomhole-assembly and drill-bit design and operation have embraced new technologies such as artificial intelligence, new materials and manufacturing techniques, and improved design software, the industry continues to research methods of optimizing delivery and understanding of already globally used technologies.

-

Few oil and gas companies give data science projects the better part of a decade to prove out, but that’s just what this one did.

-

This paper describes an 18-month intensive continuous improvement process between an operator, a rig contractor, and bottomhole-assembly (BHA) service providers aimed at reducing BHAs per well in two Oklahoma rigs.

-

This paper presents the study, resulting recommendations, and a proposed change in standard bottomhole-assembly configurations to reduce service-quality-compromising incidents and productive time lost from jar twistoffs.

-

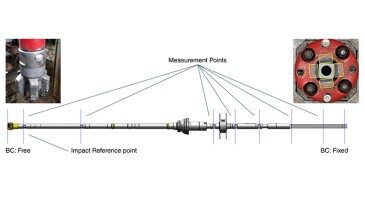

This paper discusses a full-scale drilling test rig that allows comprehensive study of the influences of bit characteristics on high-frequency torsional oscillations (HFTO) for the first time.

-

An estimated $35 billion in investment is expected to pour into geothermal projects in Kenya and Ethiopia through 2050.