Drilling

The Granat prospect on the Norwegian Continental Shelf may be developed with a subsea tieback to existing infrastructure.

Eni reports its latest deepwater exploration well offshore Côte d'Ivoire found gas and condensate in high-quality Cenomanian sands in the Calao channel complex.

Autonomous drilling through managed pressure drilling (MPD) at the Atlantis field has given the operator confidence to scale the method.

-

This paper presents an approach for automatic daily-drilling-report classification that incorporates new techniques of artificial intelligence.

-

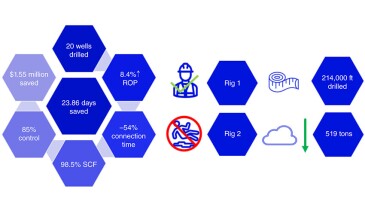

The authors of this paper present the results of implementing a rig-automation solution applied to 20 wells in Ecuador in 2022.

-

In recent years, operators and service companies have optimized drilling activities and reduced operational costs by accelerating the deployment of digital solutions. Among other applications, predictive data analytics are commonly used to estimate rock properties, reduce operational uncertainty, improve equipment maintenance processes, and optimize scarce human resou…

-

Casing deformations are common in the south-west shale regions of China and the Middle East, where the widespread use of 5.5-in., 26- and 26.8-lb/ft casing is the norm. In these regions, the majority of frac plugs are designed with an outer diameter (OD) of 4.055 in. or slightly larger, which frequently encounter restrictions resulting in the loss of bottomhole assemb…

-

The oilfield service giant said it has taken another big step toward fully autonomous drilling operations in its latest project offshore Brazil.

-

The companies have integrated their platforms in an effort to increase flexibility and interoperability.

-

Typically, oil and gas producing wells are abandoned toward the end of their life cycles with reservoir pressures depleted compared with the virgin pressures. Carbon capture and storage projects, however, present different operating conditions.

-

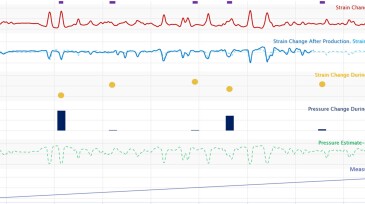

The authors of this paper describe a project in which Raleigh frequency-shift distributed strain sensing monitored during production in a far-field observation well was translated to an estimated pressure profile.

-

SponsoredWith more surface facilities and infrastructure in oil and gas fields, well casing integrity is becoming an even bigger challenge. This article sheds light on the optimum way to deal with the increasing casing integrity challenges in the Middle East through field monitoring and time-lapse casing-integrity and corrosion-inspection logging.

-

The well was spudded from the new Azeri Central East platform in the giant ACG field in the Caspian Sea.