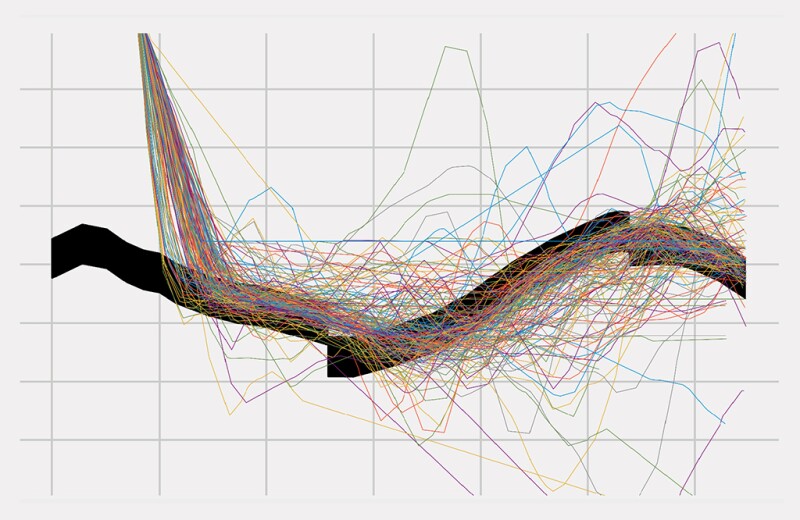

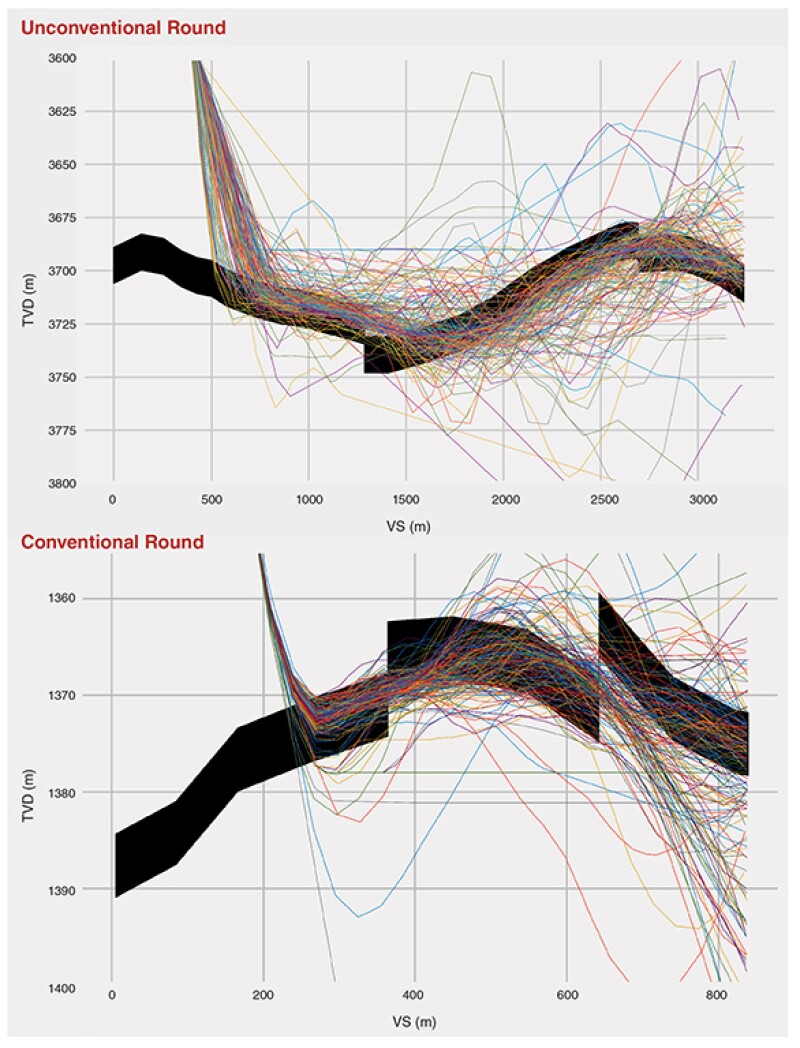

Horizontal drilling makes it possible to drill through the most-productive rock, but based on the following charts, oil companies may often be missing that opportunity.

The heavy black bars show the most-productive rock in two producing wells—one unconventional onshore and, the other, offshore and conventional.

The tangle of thin, colored lines on and around it are the well paths chosen by 329 competitors in a geosteering contest showing that many of them got lost on the way.

The charts are from a paper that analyzed 10,000 geosteering decisions made during the 2021 Rogii Geosteering World Cup, an annual competition started by the maker of geosteering software.

The work by Rogii and a team of Norwegian researchers studying drilling decision making was presented at this year’s Unconventional Resources Technical Conference (URTeC 3722510).

The results showed about half the contestants earned scores of 30% or less based on the percentage of the well in the target zone—weighted 75%—and their rate of penetration—25%. Only 14 of the 329 participants scored 60% or more, with the balance somewhere in between.

To some extent, this dim view of geosteering is a product of the contest rules.

Competitors were asked to geosteer two difficult wells at breakneck speed—a decision every 2 minutes based on data from the last 100 m drilled—with minimal information upfront about the wells chosen because they were difficult to steer. In the contest, there was no professional downside for poor performance.

Still, it is the rare public attempt to measure how well drillers do at adjusting well plans to maintain contact with the most-productive rock.

While the nature of the competition suggests it is not trying to replicate actual drilling conditions, it does raise questions about how well oil companies are doing at maximizing reservoir contact.

They observed that some top performers in one well did poorly on the next, and luck played a significant role in some of the results.

“The inconsistent performances of players in the two rounds/poor average scores/and significantly different well trajectories planned by geosteerers represent a lack of unified guidelines for stratigraphic-based steering,” Yasaman Cheraghi, a PhD fellow in computational engineering at the University of Stavanger, wrote in an email.

Geography was not a good predictor of performance. While 40% of the participants were working in North America, where the greatest number of horizontal wells have been drilled, their results were not better despite their experience.

Those involved in the geosteering simulations, based on wells in the Duverney shale in Western Canada and the Xihu Sub-Basin (Yuquan discovery) of the East China Sea, would say they were using a standard method—stratigraphic-based steering. That approach uses the data gathered while drilling and other data about the formation to predict how the layers of rock in the reservoir—the stratigraphy—are likely to change ahead of the steering.

Geosteerers are hired to adjust the well path to remain in zone, and making changes that avoid severe doglegs can cause trouble for those completing and producing the well.

The paper’s analysis of the wells drilled said the quality of the geologic data interpretation was likely to lead to better adjustments, but it is not a sure indicator of success.

Faults were a significant factor in the scores because these can require quick changes in well plans based on seismic imaging that missed them.

Many contestants in the competition did not notice they had passed faults that marked a significant shift in the productive zone, and some who did, made a wrong turn. While their scores suffered, that wasn’t always the case.

A top performer managed to keep 90% of the wellbore in zone and still missed both faults, said Stephen Clark, geophysical advisor for Rogii, who delivered the paper on behalf of the authors. That contestant was luckily on a path that was a decent match for the target zone before and after the fault.

Many others didn’t do any geosteering. Nearly half the contestants simply stuck with the path planned in the well plan, which resulted in a low score. Removing them from the results increased the percentage of contestants in the top‑performing group, but it was still low.

“There were a lot of working geologists involved—they may have had real rigs running on the side. They may not have had their full attention devoted to it,” Clark said.

“I was surprised to see those results,” said Rocky Mottahedeh, founder of a United Oil & Gas Consulting & Smart 4D Geomodeling and Geosteering Software, who described the performance charts in the paper as “a beehive of scatter and paint everywhere. It is just nonsense.”

The levels of target zone contact fall far short to his thinking, where “anything less than three-fourths is a failure,” he said adding that the “process and tools set everyone up for failure.”

The tools he is questioning do not include the ones made by his company that promise a more comprehensive view of the subsurface by preserving the detail in the 3D reservoir model and comparable wellbores to predict what is ahead.

He said more automation is needed to give geosteers better mapping and guidance at the speed of drilling.

Doing Better

When asked if the problem is solvable, Cheraghi said, “I believe it is, or at least it can be improved.”

That qualification recognizes the challenges that come with a job that requires geoscientists—most of whom are geologists—to rapidly analyze the available data and decide whether to continue on the current course or tell those in charge of drilling to change it.

The solutions revolve around focusing more on improving the process and giving the drillers tools that rapidly turn that data into drilling advice, speeding the process and allowing them to focus on whether that advice is the best option.

Automating the data acquisition and information analysis phases “takes a huge burden off the geosteerer, allowing more focus on supervision of the decision-making phase, where the expertise of the human geosteerer can make its best contribution,” said Robert Wylie, president and CEO at xnDrilling, which sells drilling automation applications.

While that could buy time for those making these adjustments on the fly, the quality of their work also depends on the oil companies’ commitment to the process.

Mottahedeh said many operators are taking a “lowest-cost-wins approach” without considering how it can affect the value of the well they drill.

“Some companies hire a team of operations geologists that plan and steer to the nth degree. They can be up at 2 in the morning, arguing about an interpretation,” Clark said, adding that others minimize geosteering spending. They may rely on a geologist tracking multiple wells in a remote center and offer limited time for preparation on unfamiliar wells.

The contest results suggest that stinting on preparation can lead to less-productive wells. Contestants were given a grid with limited information about the well ahead and many performed poorly.

Many contestants inadvertently became part of a test of whether geosteering changes actually added value if the steering was just following the well plan. The 177 persons who adopted the do-nothing strategy earned a grade around the 30% level. Removing them, the low and middle categories pushed the top-performing group to 24% of those actively geosteering the well.

Those in this group will remain anonymous. “We coded them off as numbers. They wanted to participate but want anonymity because they do not want their boss to know they did not do well,” Clark said.

Faster and Faster

In a story in the AAPG Explorer, Ed Stockhausen, a senior research scientist at Chevron whose duties then included being the geosteering advisor, described drilling a lateral as “kind of like landing a plane on a runway in the fog, when the runway is moving up and down.”

Since that story was written more than 20 years ago, the pace of drilling has gotten faster, wells are in more unpredictable rock, and laterals are far longer.

On the plus side, computers can run data-intensive advanced analytical programs far faster, making it possible to do modeling at the speed of drilling and generate advanced graphics to visualize what is ahead.

The economics of drilling puts geosteerers between two contradictory imperatives—faster drilling is needed to hold down costs, but that speeds up the already stressful job of geosteering.

The time crunch challenge was a central issue in a recent paper by Equinor which centered on the geosteering challenges in its aging Troll field (SPE 210361).

The oil target zone in the old giant field has grown narrower, and harder to follow after 25 years of production in a reservoir where the goal is to consistently drill a meter or two above the oil/water contact level and avoid the 680 wells drilled into Troll.

Geosteerers predict the oil/water contact point by plugging data from resistivity logging into an inversion equation. The time required to do that manually sets a hard limit on how fast they can drill in a zone where a 1-m error can significantly reduce future production.

The time required to calculate a new drilling instruction, get approval from the company representative, and when approved, pass it on to the driller to execute, was 13 minutes in a field where drilling averages 1 m per minute.

“The drilling steering process was becoming a bottleneck,” said Fredrik Jonsbråten, reservoir navigation supervisor for Baker Hughes, who presented the paper on a solution—automating the steering advice process—at the SPE Annual Technical Conference and Exhibition.

The Baker Hughes system can analyze the data, check it, calculate the new steering advice, and deliver it to the geosteerer in a minute. The paper said the time required for a course correction can be reduced to 3 minutes.

There was a downside mentioned in the conclusions. The computer suggests changes in the drilling settings every time it does a calculation, no matter how small.

“It’s confusing to always get new steering advice parameters to relate to, only to find that they change again at the next update,” the authors wrote in the paper. They noted that this would not be an issue if that stream of small changes was going into an automated drilling control unit which could quickly make them.

The cutting-edge software for geosteerers is starting out on the same path as directional drilling software did several years ago, when it worked like a driving navigation program offering turn-by-turn instructions. Directional drilling software has been increasingly integrated into the drilling control system, which the driller observes and only intervenes if something is amiss.

The software sold by providers like Rogii and United Oil & Gas Consulting are moving toward more digital assistance.

The software from United Oil & Gas Consulting is designed to look ahead by modeling based on the downhole data and the information in the 3D reservoir model, including offset well data. Mottahedeh said they have “collapsed the cycle time between mappings to within 5 to 10 minutes,” by automating the 3D algorithm.

Rogii has developed a program that rapidly provides geosteering recommendations. He said customers use it to provide a second opinion on decisions. It is also useful for speeding tedious tasks, such as re-steering old wellbores—simulations which can be used to take a close look at wells when assets change hands.

While some people worry about automation replacing the people doing geosteering, Clark said automation systems “will need someone on the other side considering ‘does this make sense?’”

It Is Uncertain

Computers can speed the analysis and handle data, but that won’t eliminate geosteering mistakes.

This list of uncertain things is long and, to an extent, uncertain. Even experienced geosteerers doing their job well must live with the fact that a good process does not always lead to good results.

Geosteering is done because the pre-drill well plans are based on reservoir modeling that does not always reflect reality.

Looking ahead requires modeling using downhole data from logging tools mounted well behind the drill bit, which can be affected by the heat and vibration. And laterals stretching out a mile or more regularly stray further from the planned line as the wells grow longer, within what is known as the cone of uncertainty.

Many faults are too small to detect using seismic, if it is available, and data from nearby wells may be misleading because formations change in unpredictable ways. Logging tools like gamma ray logs provide a good indication of where hydrocarbons are present, but they can be fooled by nonproductive rock.

“You’re making decisions on the spot, continuously, and you do the best you can,” Stockhausen said in the AAPG Explorer article.

Doing better is a focus for Sergey Alyaev, a senior research scientist at NORCE, who said it will require building in ways to rapidly quantify the downhole uncertainties that can significantly alter the value of geosteering decisions.

While there is a lot of interest in finding ways to describe the bedding planes in a reservoir, Alyaev, a coauthor of the geosteering competition paper, said more attention needs to be paid to the question, “How sure are you about that?”

Given the pace of drilling, the person in charge of geosteering is hard pressed just to interpret the incoming data, much less contemplating the uncertainty in it.

To put uncertainty in front of the geosteerer, Alyaev would like the look-ahead display to show multiple well paths ahead, representing the range of possibilities based on modeling that reflects the uncertainties.

This sort of display might look familiar to those who have seen hurricane prediction maps showing many possible paths for a hurricane based on multiple computer simulations. At a glance, it displays a cluster of the most-likely outcomes, as well as low-odds possibilities around the edges.

Others question whether geosteerers who are already struggling to digest the available information could also consider uncertainty while making rapid-fire decisions.

Alyaev responds to those objections with studies showing humans are bad at making quick decisions when presented with a complex, uncertain problem to solve.

To make his point, Alyaev created an algorithm that made steering decisions in a simulation that included uncertainty and compared its automatic results with the steering decisions made by 54 professionals. Only two outperformed the algorithm (SPE 204133).

From there, he created a geosteering robot designed to compete in the Rogii contest. “My first attempt in 2019 did horribly ... for that matter, Rogii has their own robot, and it didn’t do well back then,” he said. He and Rogii have continued to work on improving these systems. He is developing one using artificial intelligence but did not enter it in this year’s competition. The Rogii system was available to contestants at this year’s competition.

Alyaev said it is a slow process in part because there’s little funding available for uncertainty-based geosteering automation research. He has been working on the problem since he was involved in an industry‑supported geosteering research project in Norway in 2018.

Alyaev’s team suggested totally new workflows. The industry partners responded that those ideas were incompatible with their current practices. “What they [the industry] were really after is to take the status quo and make it better,” he said, adding that over time he expects the research will converge with how geosteering is done.

For Further Reading

URTeC 3722510 What Can We Learn After 10,000 Geosteering Decisions? by Yasaman Cheraghi, University of Stavanger; Sergey Alyaev, NORCE; Aojie Hong, University of Stavanger; Igor Kuvaev, Stephen Clark, and Andrei Zhuravlev, Rogii Inc.; and Reidar Brumer Bratvold, University of Stavanger.

SPE 210361 Automating Log Interpretation for Optimal Well Placement and Increased Drilling Efficiency by Fredrik Jonsbråten, Baker Hughes; Marianne Iversen, Kåre Røsvik Jensen, Monica Vik Constable, and Hilde Haktorson, Equinor, et al.

SPE 204133 Systematic Decisions Under Uncertainty: An Experiment Towards Better Geosteering Operations by Sergey Alyaev and Andrew Holsaeter, NORCE; Reidar Brumer Bratvold, University of Stavanger; Sofija Ivanova and Morten Bendiksen, Bendiksen Invest og Konsult.