Drilling

An earlier deal to double Israel’s gas exports to Egypt led to approval of Leviathan’s Phase 1B expansion by guaranteeing long-term cash flow to finance the project.

Rystad Energy expects the continent to account for the largest share of frontier and basin-opening wells in 2026 as operators pursue scale and untapped resources.

This paper presents a multifaceted approach leveraging precise rig control, physics models, and machine-learning techniques to deliver consistently high performance in a scalable manner for sliding.

-

This paper details new technologies and work flows implemented for Australian offshore wells to improve drilling efficiency while managing associated risks.

-

The paper demonstrates the application of an interpretable machine-learning work flow using surface drilling data to identify fracable, brittle, and productive rock intervals along horizontal laterals in the Marcellus shale.

-

E&P independent Energean has awarded Halliburton a contract to provide services for drilling up to five wells offshore Israel in collaboration with Stena Drilling.

-

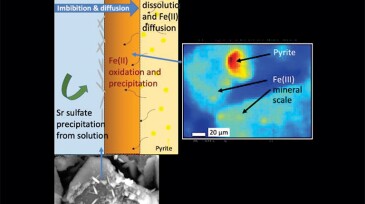

The obsession with better hydraulic fracturing has steadily pushed on shale production in year one, but the decline remains steep. Chemistry could help explain, and perhaps extend, the short productive life of these wells.

-

ADNOC will purchase eight FlexRigs while H&P invests in ADNOC Drilling’s planned public offering.

-

SponsoredExtended reach wells provide access to otherwise inaccessible areas, improve production and reduce footprint. Advancements in completion technology allow producers to eliminate coiled tubing, perforation guns and milling out operations to lower project risks, costs, and environmental impact.

-

In a natural pivot from oil and gas E&P, former oilfield executives are taking up the hunt for helium. Helium is used in a wide variety of products, such as rocket ships and computer chips, and, while there is still plenty left to find on Earth, finding quality commercial quantities can be a difficult task and reserves are running low.

-

SponsoredBefore you pump materials down your well, be sure you fully understand the effectiveness of your friction reducers and gas migration slurries.

-

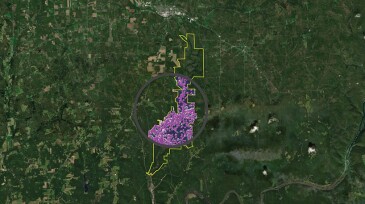

The impact of orphan wells, both on the environment and on tightening budgets, is a growing concern in the industry. Boom times result in a vast uptick in wells drilled. In bust times, when companies disappear, the liability outlook for these probes gets murky and federal and state governments start looking for answers.

-

Extended-reach drilling is becoming more of a mainstream technology as the industry seeks to squeeze difficult reserves and reduce the footprint of projects in fragile environments.