Drilling

Rystad Energy expects the continent to account for the largest share of frontier and basin-opening wells in 2026 as operators pursue scale and untapped resources.

This paper presents a multifaceted approach leveraging precise rig control, physics models, and machine-learning techniques to deliver consistently high performance in a scalable manner for sliding.

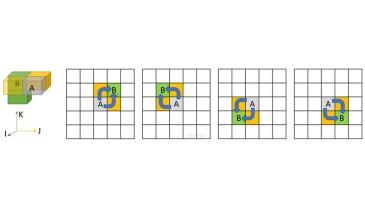

This paper proposes a novel approach toward drilling maximum-reservoir-contact wells by integrating automated drilling and geosteering software to control the downhole bottomhole assembly, thereby minimizing the need for human intervention.

-

This article is the fourth in a Q&A series from the SPE Research and Development Technical Section focusing on emerging energy technologies. In this piece, David Reid, the CTO and CMO for NOV, discusses the evolution and current state of automated drilling systems.

-

This paper presents an efficient mathematical optimization method for well placement that maximizes contact with the productive zones for the best locations in the reservoir.

-

The operator estimates discovering more than 96 million BOE of recoverable volumes with its latest Norwegian North Sea exploration activity.

-

SponsoredKongsberg Digital’s mobile companion to the SiteCom platform is designed to keep wellsite insight close at hand, wherever the job takes you.

-

The new schedule plans for sales in the US Gulf and Alaska through 2039.

-

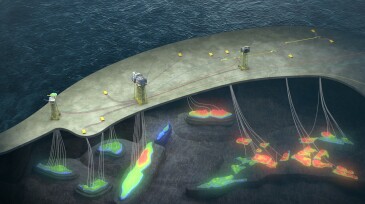

Researchers with the National Energy Technology Laboratory showed that naturally occurring signals in underground fluids can serve as effective indicators of flow patterns between existing wellbores. Understanding these patterns can lead to increased efficiency and safety.

-

The number of high-impact wells drilled across the globe this year are expected to be on trend with the most recent 5-year average.

-

This study explores enhancing gas production through a novel combination of prestimulation using a coiled tubing unit and high-rate matrix acidizing.

-

Bad vibes are being addressed by contractors as operators push to go faster, deeper, and longer with unconventional wells.

-

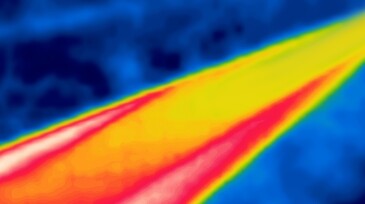

Traditionally, the drilling industry has relied on high-fidelity thermal simulators to predict downhole temperature for different operational scenarios. Though accurate, these models are too slow for real-time applications. To overcome this limitation, a deep-learning solution is proposed that enables fast, accurate prediction of downhole temperatures under a wide ran…