Drilling

The deal positions the merged company to benefit from an expected offshore drilling upcycle.

An earlier deal to double Israel’s gas exports to Egypt led to approval of Leviathan’s Phase 1B expansion by guaranteeing long-term cash flow to finance the project.

Rystad Energy expects the continent to account for the largest share of frontier and basin-opening wells in 2026 as operators pursue scale and untapped resources.

-

A major operator manages multiple deepwater projects in the Gulf of Guinea. This paper describes one of these, a recent 44-well project.

-

This paper discusses shale creep and other shale-deformation mechanisms and how an understanding of these can be used to activate shale that has not contacted the casing yet to form a well barrier.

-

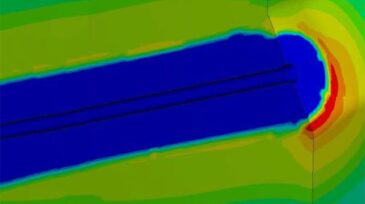

Hydraulic isolation of wells drilled with nonaqueous fluids (NAFs) relies heavily on eliminating mud from the annuli before placing cement.

-

This paper demonstrates a new way to create gas-tight seals during well abandonment, overcoming the limitations of traditional methods and reducing the operator’s liability and potential environmental impact after decommissioning has been completed.

-

I am encouraged that we, as an industy, continue to refine and tweak our practices to solve zonal-isolation and cementing challenges in every well environment in which we work. As cementing techniques are improved, so, too, are the cement-evaluation methods and work flows.

-

Against the background of a low-oil-price environment, a redevelopment project was launched to give a second life to a shallow, depleted, mature offshore Congo oil field with viscous oil (22 °API) in a cost‑effective manner.

-

This paper presents the data collected by an ultrasound downhole scanner, demonstrating a novel method for diagnosing multilateral wells.

-

This paper describes challenges faced in a company’s first deepwater asset in Malaysia and the methods used to overcome these issues in the planning stage.

-

The oil industry is currently undergoing a technological transformation that will add value, improve processes, and reduce cost. Future drilling engineers will have knowledge of robotics, automation, and organizational efficiency, which is highly appealing for recruitment.

-

The deal will bolster Arabian Drilling Company’s fleet to 67 rigs across the Middle East and North Africa.