Drilling

Oil and gas companies drilled 75 “high-impact” wells in 2024, representing 5.2 billion BOE.

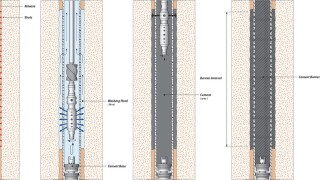

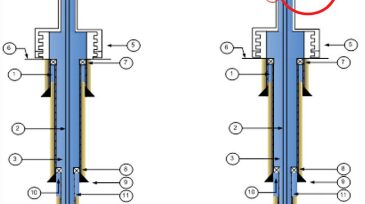

This paper presents a comprehensive literature review of perforate, wash, and cement techniques that compares new methods with traditional ones and uses field cases and computational fluid dynamics to find the most cost- and time-effective practices without sacrificing safety.

The authors of this paper describe a method of stimulating a multizone hydrocarbon-producing well wherein a tool is deployed downhole by wireline to generate acid vapor at a target depth, allowing each interval to be treated uniquely.

-

Managed-pressure drilling (MPD) challenges the conventional drilling paradigm, along with drilling-contractor and operator policies and standards. Conventional drilling practices for connections, flow checks, tripping, and well control have been long understood and standardized.

-

In this study, pressure-while-drilling technologies are combined with software simulations to differentiate drilling-fluid thermal expansion, wellbore ballooning, and formation influx during riserless drilling operations.

-

A fluid technology has been developed to deposit a thin, impermeable barrier over the pores and microfractures of weak, underpressured, and otherwise troublesome formations to maintain wellbore stability and reduce formation damage.

-

Finding niches that provide a competitive edge over larger operators has enabled Talos Energy to leapfrog into a powerful position with Mexico’s first offshore wildcat discovery.

-

In the past, most wells have been drilled using conventional methods, but the landscape is changing as economic pressures have forced the drilling industry to refocus.

-

Bottomhole assemblies (BHAs), as part of the drilling system, have dominating effects on the functionality and effectiveness of other system components. BHA design, usage, and monitoring must promote drilling-system compatibility, efficiency, and reliability.

-

Correct placement of the rotary-speed sweet spot of a bottomhole assembly (BHA) provides multiple benefits toward achieving the ultimate goal of drilling to section total depth in a single trip.

-

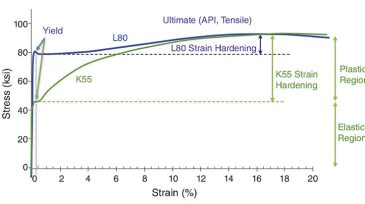

Microdoglegs are a natural effect of any vertical or directional well that can explain a wide variety of downhole problems.

-

A new fatigue-management work flow provides drillers with a tool to simulate and predict the life expectancy of bottomhole assemblies (BHAs) before fatigue causes problems.