Drilling

The London-headquartered independent acquires position in the US Gulf while preparing Zama for final investment decision.

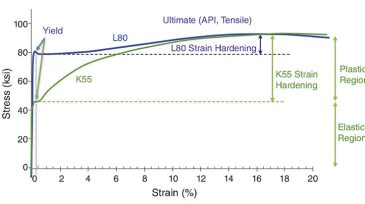

This study identifies critical knowledge gaps in wellbore integrity and underscores areas that require further investigation, providing insights into how wellbores must evolve to meet the technical demands of the energy transition.

This study illustrates the new capabilities, tailored for CO₂ storage applications, of a modeling framework that provides a quantitative, risk-based assessment of the long-term integrity of legacy plugged and abandoned wells.

-

Major oil discoveries by Armstrong Oil & Gas and ConocoPhillips have compelled the US Department of the Interior to reassess its estimate of undiscovered, technically recoverable resources in parts of Alaska.

-

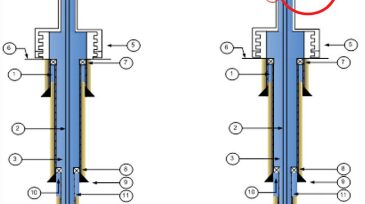

Nonaqueous drilling fluids have been used extensively by the industry, particularly in complex drilling scenarios. They carry some concerns, however, with implications for well integrity.

-

Managed-pressure drilling (MPD) challenges the conventional drilling paradigm, along with drilling-contractor and operator policies and standards. Conventional drilling practices for connections, flow checks, tripping, and well control have been long understood and standardized.

-

In this study, pressure-while-drilling technologies are combined with software simulations to differentiate drilling-fluid thermal expansion, wellbore ballooning, and formation influx during riserless drilling operations.

-

A fluid technology has been developed to deposit a thin, impermeable barrier over the pores and microfractures of weak, underpressured, and otherwise troublesome formations to maintain wellbore stability and reduce formation damage.

-

Finding niches that provide a competitive edge over larger operators has enabled Talos Energy to leapfrog into a powerful position with Mexico’s first offshore wildcat discovery.

-

In the past, most wells have been drilled using conventional methods, but the landscape is changing as economic pressures have forced the drilling industry to refocus.

-

Bottomhole assemblies (BHAs), as part of the drilling system, have dominating effects on the functionality and effectiveness of other system components. BHA design, usage, and monitoring must promote drilling-system compatibility, efficiency, and reliability.

-

Correct placement of the rotary-speed sweet spot of a bottomhole assembly (BHA) provides multiple benefits toward achieving the ultimate goal of drilling to section total depth in a single trip.