Drilling

The London-headquartered independent acquires position in the US Gulf while preparing Zama for final investment decision.

Two critical facets of the discipline of well control and wellbore integrity—decarbonization and groundbreaking automation of essential processes—are highlighted in the three primary paper selections presented at SPE and SPE-affiliated conferences during the past year.

This study identifies critical knowledge gaps in wellbore integrity and underscores areas that require further investigation, providing insights into how wellbores must evolve to meet the technical demands of the energy transition.

-

During the optimization process, the Castilla field became the model of management strategies for the rest of the fields in the company portfolio.

-

Integration of technology applications is paramount in increasing the success rate of data delivery.

-

-

The general industry perception is that, when drillstrings or casing strings exceed conventional helical-buckling criteria, they cannot be operated safely in the hole because the risk of failure or lockup is too high.

-

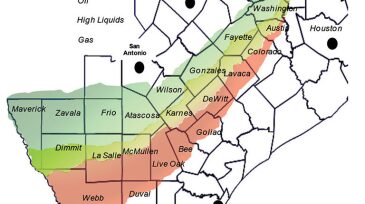

The producing assets of unconventional shale-gas and shale-oil plays in North America are among the strategic alternatives for future growth of exploration-and-production companies.

-

ExxonMobil, operator for the Sakhalin-1 project, planned an additional drilling campaign at the Chayvo field, Sakhalin Island, Russia.

-

In 2012, the number of unconventional tight gas/shale and high-pressure/high-temperature (HP/HT) papers continued to grow. This year, we had some very interesting developments in these and other areas of well construction.

-

This case history presents the highly challenging extended-reach deepwater well, Ursa A-10, drilled in the Ursa (Latin for bear) prospect in the US Gulf of Mexico (GOM).

-

The Eagle Ford shale in Zavala County, Texas, is similar to many high-carbonate-content oil-shale formations.

-

To maintain zonal isolation throughout the life of a high-pressure/high-temperature (HP/HT) well, the cement sheath must perform reliably at temperatures that can exceed 315°C.