Field/project development

Vår Energi ASA and partners have officially sanctioned the Previously Produced Fields Project in the Greater Ekofisk Area. The redevelopment is expected to add high-value barrels starting in 2028, extending the production life of one of Norway’s key offshore regions.

The company engineered, designed, and manufactured multiple internal floating roof systems and tank-top equipment packages for TotalEnergies’ new storage terminal in Equatorial Guinea.

Fugro’s entry into the UK’s small modular reactor market follows its breakthrough in the US, where it secured a contract in February to perform a geoscience site investigation for the recommissioned Palisades Nuclear Power Plant in Michigan.

-

The facility for open-source carbon capture, transport, and storage has been completed.

-

The joint venture will be responsible for engineering, procurement, construction management, and commissioning of the planned 16.5-mtpa facility.

-

Using a new model, the federal agency said deepwater operations will drive the region's production to 1.9 million B/D next year.

-

The field's massive FPSO is anchored in place and on schedule for first oil prior to year-end.

-

The updated plan seeks to avert termination of the PSA by raising total investment and constructing a floating production unit at Aphrodite plus an export pipeline to Egypt.

-

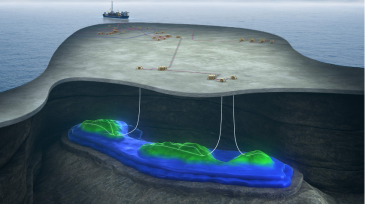

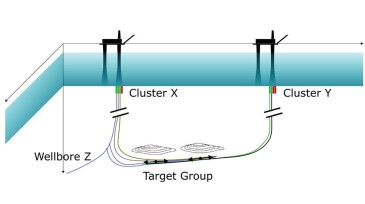

Subsea tieback in the Central North Sea expected to produce 20,000 BOED at peak, boosting output to Alvheim FPSO.

-

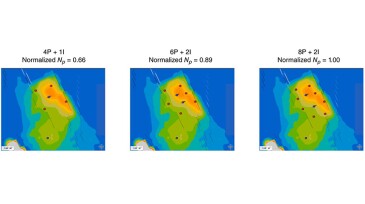

This paper presents a multidisciplinary view of the evolution of a development project for the central area of Sururu and the method applied to address challenges and propose solutions.

-

This paper proposes a method to radically revise the well-path-generation process to reach the vision of planning a well in one day with high quality, relying on the collection of experience-based constraints from each discipline to generate possible alternatives.

-

Since the late 1930s, the offshore industry has advanced from the first platform in 14 ft of water to the ultradeepwater 20K era. Driven by seismic, drilling, and development breakthroughs, the industry has pushed into deeper waters, high-pressure reservoirs, and new frontiers like Guyana, continually expanding the limits of offshore exploration.

-

Fervo Energy proved fracturing can harvest geothermal energy and is now rapidly learning to build a utility-scale power plant.