Inspection/maintenance

Sponsored

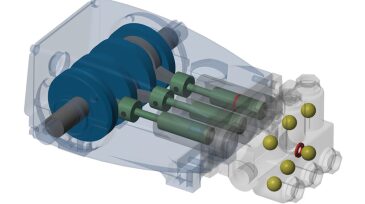

As HPHT wells push equipment to the edge of material limits, operators are turning to advanced thermoplastics and sealed electrical assemblies to maintain system integrity. From ESP insulation to BOP control systems, the right component design can prevent failures, lower intervention costs, and extend equipment life in the harshest offshore environments.

This paper presents an approach to management and interpretation of pipeline-integrity data, ensuring integrity, safety, and reliability of the operator’s critical pipelines.

This paper describes the development of a system for comprehensive mapping and asset registration using a digital-twin approach.

-

The maritime technology company successfully completed a remote deadweight audit for a semisubmersible oil and gas drilling rig. Believed to be the first of its kind, the remote survey was developed in response to travel and social-distancing restrictions imposed during the COVID-19 pandemic.

-

Using 3D and artificial intelligence technologies, a digital map of all three bridge-linked jackets was captured, enabling Neptune to detect asset-integrity issues early and plan fabric maintenance work on Cygnus.

-

The fully remote inspection was conducted with an ROV to increase worker safety and security and reduce environmental exposure on an offshore platform.

-

Often it is too difficult to create the fault conditions necessary for training a predictive maintenance algorithm on the actual machine. A digital twin generates simulated failure data, which can then be used to design a fault-detection algorithm.

-

With their gee-whiz—albeit artificial—intelligence, robots may be the industry’s answer to jobs deemed dangerous, dirty, distant, or dull.

-

The inspection projects to assess water ingress will be done via remotely operated vehicle.

-

iHawk, Cyberhawk’s cloud-based asset visualization software, will become Shell’s next-generation visualization software platform for all onshore, offshore, and subsea assets, as well as all global construction projects.

-

The contract continues the two companies’ 8-year working relationship; in 2012, they performed the world’s-first underdeck inspection.

-

A recent test proved the feasibility of using LiDAR on remote-controlled drones to create 3D maps of the inside of tanks, increasing the safety and efficiency of inspections.

-

Three-dimensional seismic technology helped unlock more subsurface secrets for oil and gas operators. Now, 3D technology can be used in scanning, a cutting-edge technology that engineers can use to plan upgrades to oil and gas assets virtually.