Inspection/maintenance

The Norwegian major said it is using artificial intelligence for predictive maintenance throughout its facilities and for interpretation of seismic data from the Norwegian continental shelf.

Sponsored

As HPHT wells push equipment to the edge of material limits, operators are turning to advanced thermoplastics and sealed electrical assemblies to maintain system integrity. From ESP insulation to BOP control systems, the right component design can prevent failures, lower intervention costs, and extend equipment life in the harshest offshore environments.

This paper presents an approach to management and interpretation of pipeline-integrity data, ensuring integrity, safety, and reliability of the operator’s critical pipelines.

-

The digitalization of oil and gas facilities is becoming a new technical arena. Effective solutions can be used to convert data into information and knowledge, which can then be used to improve maintenance operations.

-

Intel and Cyberhawk released a case study outlining the successful inspection of a gas terminal near the coast of Scotland using commercially available drone technology.

-

Operators need to take steps to protect their facilities from drone security breaches by outsiders. The costs an attacker incurs in developing tools to break into and control infrastructure is low compared to the costs an operator incurs in defending against those tools.

-

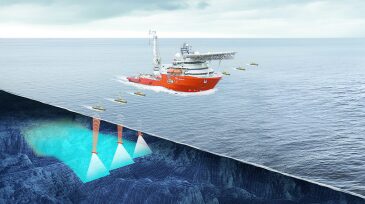

AUVs aren’t limited to inspections and pipeline surveys. Deployment of a flotilla of AUVs to work on a project, and the communication among them, may someday lead to a subsea Internet of Things.

-

Current methods for external inspection of floating assets on station use divers or remotely operated vehicles (ROVs), but these methods incur high safety, people-on-board (POB), and cost penalties. New methods to eliminate diving are being developed.

-

A closer look at recent unmanned aerial vehicle (UAV) regulations and sensor technologies shows the areas in which they could have a major impact on oil and gas projects in the future.

-

Visualization technology has played a key role in reducing operational expenditure (OPEX) and improving collaboration, thus maximizing uptime across the industry throughout the asset life cycle.

-

Since the recent oil price downturn, the offshore MMO market has witnessed a significant decline in global expenditure. The most severe decline in total regional expenditure is anticipated to occur in North America, with modifications expenditure forecast to drop by 56% between 2014 and 2016.

-

Optimization of maintenance costs is among operators’ main concerns in the search for operational efficiency, safety, and asset availability. The ability to predict critical failures emerges as a key factor, especially when reducing logistics costs is mandatory.

-

As subsea electric lines age, they are prone to cracks that allow seawater in, reducing their effectiveness, and if the leaks are bad enough, they can shut down operations.