Onshore/Offshore Facilities

The Granat prospect on the Norwegian Continental Shelf may be developed with a subsea tieback to existing infrastructure.

The planned facility was designed to process 34 MMcf/D of associated gas into fully refined gasoline.

The awards build on Tenaris’ role in earlier phases of the ultradeepwater Black Sea project.

-

Vibration-induced fatigue failures of pipework smallbore connections result in elevated safety risks and costly interruptions to normal operations. A common cause is poor design. This article discusses design considerations to avoid these failures.

-

This paper focuses on the applicability of subsea processing technology employing multiphase pumps to develop marginal fields commercially. Analytical methods were used to evaluate the pumps, and the results were validated through case studies in specific fields.

-

As environments become more challenging, the importance and complexity of flow assurance has evolved. To effectively manage flow assurance, oil and gas operators must take a holistic approach, particularly when working in deepwater offshore environments.

-

The growing amount of heavy crude processed worldwide has created additional separation challenges, leading some operators to turn to alternative technologies. In some cases, electrocoalescence has been an effective tool to separate oil from water.

-

Expenditure is forecast to increase more than operational days because of the move toward deeper waters and more complicated offshore field development programs, which demand higher specification, higher cost ROVs.

-

A recent webinar focused on hydrocyclones and their application for offshore oil and water separation. The discussion includes fundamental science, practical considerations, implementation and field experience.

-

Robotic submarines, capable of operating by themselves thousands of feet underwater for months or perhaps years at a time, are under development as the vanguard of tomorrow’s subsea oil and gas fields.

-

Industry perceives decommissioning projects as more risky and uncertain than capital projects. Several recent decommissioning projects delivered in an immature marketplace seem to support this view.

-

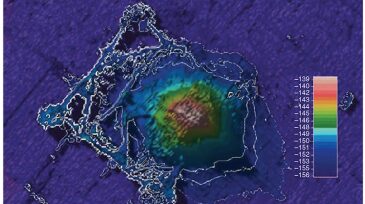

Advances in modeling techniques allow quantitative prediction of long-term trends in cuttings-pile characteristics and environmental risks, providing firm direction in mitigating risks.

-

The great majority of wells do not pollute.