Processing systems/design

The $100-billion project is widely considered the largest unconventional development outside of the US and is noted by Aramco as the largest nonassociated gas development in the kingdom.

The research facility said it plans to add multiphase-flow-testing capabilities for heavy oil and different viscosities.

This paper presents an approach to management and interpretation of pipeline-integrity data, ensuring integrity, safety, and reliability of the operator’s critical pipelines.

-

Subsea processing is an evolving technology in ultradeepwater development and has the potential to unlock a significant amount of hydrocarbon resources. In this paper, the authors have reviewed the application of subsea systems in 12 deepwater fields and discussed the significance of each.

-

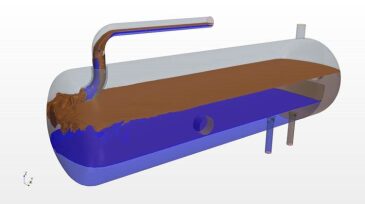

Why CFD should be part of your separator design? This goal of this goal is to allay any fears about CFD that you may have as a result of flashbacks to university class and a dizzying array of partial-differential equations.

-

Despite the currently deteriorating oil and gas prices, natural gas, the “least carbon-intensive” fossil fuel, is still projected by ExxonMobil, the International Energy Agency, and other sources to grow by 65% from 2010 to 2040

-

Historically, the marine systems on a spar are relatively simple.

-

The sources and magnitude of shear and the effects on oil droplet size can have significant consequences for downstream separation equipment performance.

-

Lessons learned by the members of the SPE Separations Technology Technical Section, representing more than 250 years' experience, are presented so that the same mistakes are not repeated in the future.

-

The technology described by the authors provides the simplicity of a single-step distillation process for the separation of CO2 from natural gas. The technology has shown the potential to separate CO2 and other impurities from natural gas more efficiently and more cost-effectively.

-

An underperforming scrubber that was suffering from too much oil carry-over is described along with options for debottlenecking and improving performance.

-

Efficient separation assumes uniform flow, but the reality of inlet geometries can invalidate this assumption, leading to separation problems and loss of separation efficiency.

-

Some internals components affect a separator's gas- and liquid-handling capability because of their effects on the liquid level. In this article, the interdependency of cyclonic inlets, cyclonic mist eliminators, and liquid level is highlighted.