Separation/treating

The research facility said it plans to add multiphase-flow-testing capabilities for heavy oil and different viscosities.

In this final installment of the Savvy Separator Series (No. 23), the authors present a curated collection of recommended references, articles, and other key resources—a comprehensive guide worth reading, bookmarking, and keeping in your library.

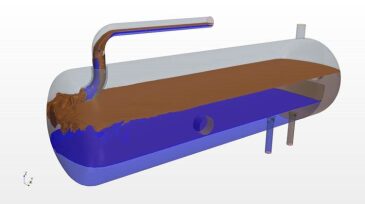

With the right internal modifications, traditional degassers can be enhanced with gas flotation for improved oily water separation. This article outlines key design considerations—including inlet and settling zones, skimming, and solids handling. Two case studies highlight lessons learned in troubleshooting and revamping degasser designs.

-

Why CFD should be part of your separator design? This goal of this goal is to allay any fears about CFD that you may have as a result of flashbacks to university class and a dizzying array of partial-differential equations.

-

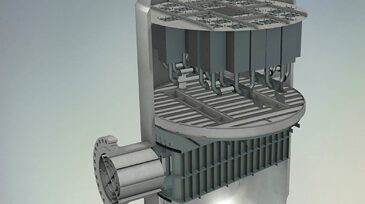

The main drivers for sizing gas scrubbers have been performance requirements, process conditions, and project specifications. However, optimizing cost, delivery times, and weight is not the same as improving scrubber performance.

-

The sources and magnitude of shear and the effects on oil droplet size can have significant consequences for downstream separation equipment performance.

-

Oil and gas wells often produce sand or solids with the well fluids. Despite exclusionary well designs, these solids can cause equipment failure, completion problems, or changes in production. This paper offers a way to remove solids in separators.

-

Lessons learned by the members of the SPE Separations Technology Technical Section, representing more than 250 years' experience, are presented so that the same mistakes are not repeated in the future.

-

Computational fluid dynamics modeling has proven promising for improving scrubber performance.

-

In its fifth year, the Separations Technology Technical Section has grown to more than 1000 members. The new section chair provides his perspective on what the future holds.

-

An underperforming scrubber that was suffering from too much oil carry-over is described along with options for debottlenecking and improving performance.

-

To support subsea processing of heavy crudes, an inline electrocoalescer was tested for separation of water droplets dispersed in the crude oil.

-

Learn how different inlet designs affect fluid dynamics and ultimately scrubber performance.