Offshore/subsea systems

The company has installed an autonomous drone system on Aker BP’s Edvard Grieg platform in the North Sea, enabling frequent, remote inspections from shore.

Once labeled “undrillable,” Brazil’s heavy-oil Atlanta field in the Santos Basin faced technical, financial, and logistical challenges. But through a phased approach, clever reuse of assets, and disciplined project execution, Brava Energia transformed a risky deepwater asset into a producing field with 172 million BOE in 2P reserves.

This paper describes the use of coiled tubing in a pilot project for carbon dioxide injection, enabling evaluation of the conversion of an existing oil field for CCS purposes and derisking storage-development uncertainties before having to cease hydrocarbon production.

-

A new tool enables variable bore rams and shear rams to be tested in one run, cutting rig time significantly.

-

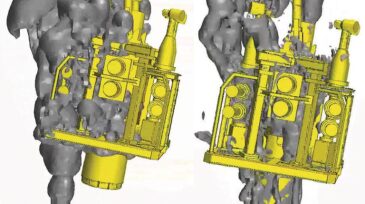

Developing a well-specific subsea-capping contingency plan involves assessing the feasibility of deploying a capping stack from a floating vessel, determining the weight and stability, and performing dynamic-flow simulations of closing the capping stack outlets.

-

Subsea tieback of a new field to an existing offshore production facility is one option to minimize development costs.

-

This paper presents the development of Sapinhoá field, covering the fast-track transition and decision-making process, from appraisal to conceptual and basic engineering of the Sapinhoá pilot project and on to its subsequent execution, highlighting the challenges, lessons learned, and results.

-

Subsea processing is an evolving technology in ultradeepwater development and has the potential to unlock a significant amount of hydrocarbon resources. In this paper, the authors have reviewed the application of subsea systems in 12 deepwater fields and discussed the significance of each.

-

Successful rejuvenation of two declining fields was enabled through innovation in both engineering and procurement strategy.

-

The deepwater industry uses technology qualification (TQ) as a tool to determine which safety barriers are needed, and what level of testing is required. Even without failure data from the field, a method has been developed to quantify the integrity of various components.

-

Intervention and workover operations can significantly affect the structural integrity and fatigue life of subsea-wellhead systems. Methodologies for wellhead-fatigue analysis have improved, but have yet to account for thermal effects along the well. This study analyzes those thermal effects.

-

The sharp downturn in the offshore oil business has sparked interest in using subsea pumps to add production. If those conversations turn into orders, it may convert this rarely used option into a commonly used tool for extending the life of offshore fields.

-

As it has since 1969, the world came to OTC to make critical decisions, share ideas, and develop business partnerships to meet global energy demands.