Torsional dynamics can be extremely damaging to downhole drilling tools and can significantly affect drilling efficiency. The effort to prevent this phenomenon has led to the development of various downhole mitigation tools, improved bit technologies and bottomhole-assembly (BHA) designs, and better management of drilling parameters. This paper outlines two lesser-known types of torsional dynamics observed while drilling interbedded carbonate formations in the Middle East with the latest generation in point-the-bit rotary-steerable systems (RSSs).

Introduction

Aspects of dynamic behavior considered to be particularly undesirable include the following:

- Large fluctuations of bit-rotation rate (ω) and the often-associated amplitude modulation of higher-frequency vibrations. [These features are usually ascribed to stick/slip behavior, wherein ω is periodically zero, then much larger than the rotation rate at surface (Ω). Potentially, stick/slip could also occur at positions in the drillstring other than the bit.]

- Backward whirl, where the bit rolls around the (enlarged) borehole in a sense opposite to Ω.

Resonances of the drill-string may drive or be driven by Items 1 and 2; enlarged or irregularly shaped boreholes are likely to be involved.

Background

A major mainland oil and gas field in the Middle East is notorious for difficult and hazardous drilling conditions; high levels of stick/slip are the norm.

The RSS has a number of onboard dynamics sensors. The two discussed in this paper are

- RSS whirl-average indicator. This consists of accelerometers, which are mounted radially (to the drillstring centerline) and measure changes in centripetal accelerations. These are used to infer the severity of off-hole centerline rotation (i.e., whirl). This measurement has an effective sample rate of 40 Hz at 100 rev/min. A whirl-severity indication is then transmitted in real time to the surface.

- RSS stick/slip average. This sensor monitors changes in the RSS rev/min measurement over a given sample period. The RSS measures rev/min at an equivalent sample rate of 1 Hz. It is therefore suitable only for detecting torsional dynamics (rev/min changes) that occur at up to 1 Hz.

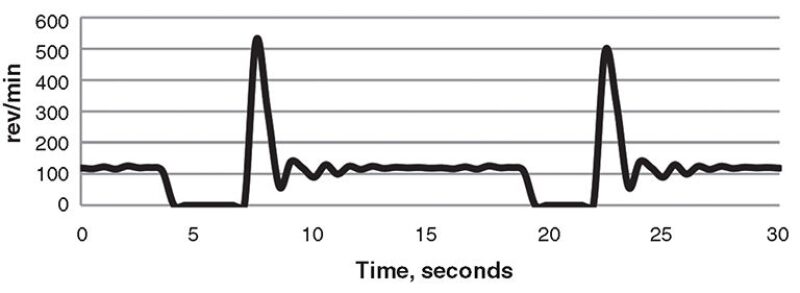

The conventional representation of stick/slip can be seen in Fig. 1. This is typical of the rev/min traces experienced elsewhere in the world and is of sufficiently low frequency that it can be detected easily by existing measurements. This low-frequency stick/slip is not particularly damaging to drillstring components.

Although reported stick/slip levels in this particular field are usually severe, the amount of drillstring/drilling-tool damage experienced is disproportionately high compared with that experienced in other fields with similar levels of reported stick/slip. The literature suggests that harmonic/sinusoidal torsional dynamics can occur at significantly higher frequencies than the 1 Hz that existing onboard sensors are capable of detecting. It was apparent that the severity of the drilling environment in this field was not reflected accurately in RSS-sensor data.

Field Test

High-sample-rate downhole dynamics sensors (DDSs) were placed at two different locations in the BHA. A near-bit DDS and a string DDS were positioned 1.5 and 107 ft above the bit, respectively. The DDS had a sample rate of 800 Hz and consisted of an accelerometer package measuring lateral, torsional, and axial vibration. The DDS also included a magnetometer, which was used to calculate downhole rev/min values. A low-pass filter (<10 Hz) was applied to the magnetometer signal.

The test BHA consisted of an 8.5-in.-diameter polycrystalline-diamond-compact drill bit, a point-the-bit RSS, an integrated directional sensor, a multifrequency resistivity tool, azimuthal density and thermal neutron porosity tools, and a hostile-environment-logging tool. This BHA configuration is known as the RSS Triple Combo.

The data discussed in this paper were obtained from an RSS Triple Combo run in this particular field in August 2011. The RSS drilled the build section between 7,310 and 8,193 ft to an inclination of 26.1°. A total distance of 883 ft was drilled, with an average rate of penetration of 41 ft/hr.

The lithology of this section consisted of interbedded carbonates and shale. The shallowest formation, the Shilaif [6,792- to 7,401-ft true vertical depth (TVD)], is a succession of argillaceous limestones, mostly fine-grained packstone and wackestones together with subordinate calcareous shales in the lower part. The next formation, the Maudud (7,401- to 7,465-ft TVD), is thinly developed and consists of bioclastic and foraminiferal wackestone and packstone. The final formation, the Nahr Umr (7,465- to 8,277-ft TVD), consists of a sequence of variegated shales with some rare sand -lenses, glauconitic silts, and occasional beds of limestones, mostly packstone and wackestone.

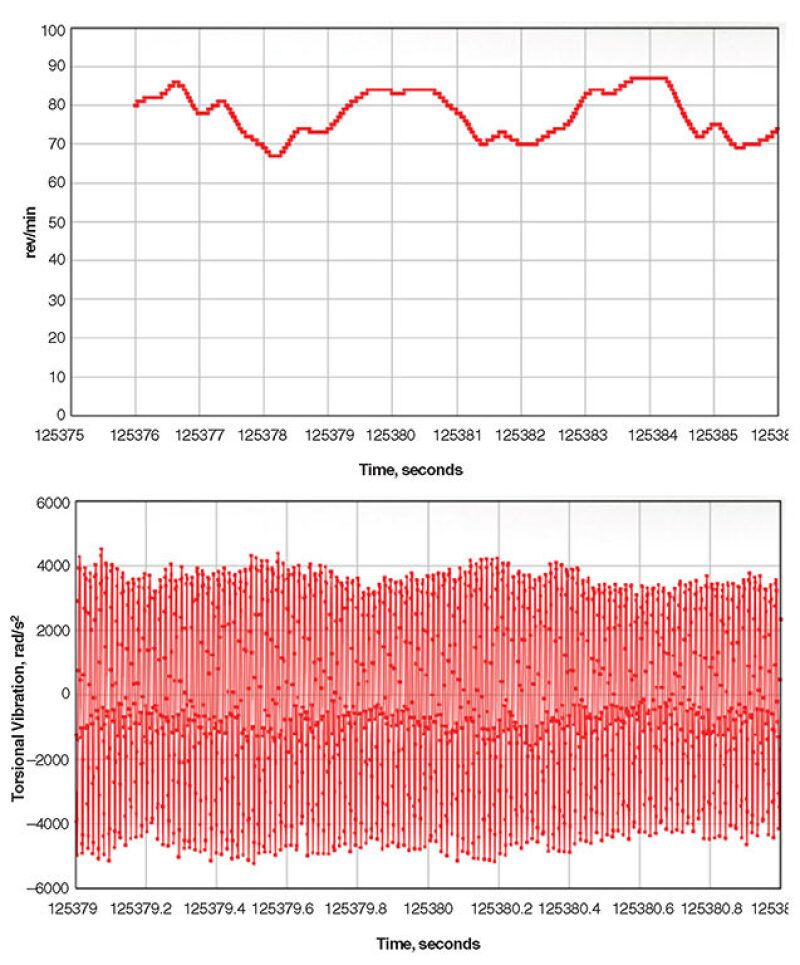

Two torsional phenomena were observed in the DDS data: (1) a low-frequency (approximately 0.3-Hz) rev/min oscillation measured by the DDS magnetometer and (2) a high-frequency (approximately 66-Hz), high-amplitude (10 000-rad/s2) angular acceleration measured by the DDS accelerometer package. Both phenomena were observed to occur individually and simultaneously.

Low-Frequency rev/min Oscillation. During this period, surface rotary speed was 100 rev/min. The maximum rev/min observed ranges from two to three times the average surface value. In this particular record, the peak rev/min value at the string DDS is larger than that at the near-bit DDS. Note that near-bit- and string-DDS measurements were not precisely synchronized, so no phase relationship can be determined.

It was also noted that, although the magnitude of the high-frequency angular acceleration was low (<400 rad/s2), the signal contained a dominant frequency component at 66 Hz irrespective of rotary speed. This would suggest that (a) a fundamental resonance occurs within the BHA at this frequency and that (b) drilling conditions at this particular point in the well were insufficient to excite it.

High-Frequency Angular Acceleration. High-frequency angular accelerations detected by the near-bit-DDS accelerometer package can be seen in Fig. 2. The resonance observed earlier is now excited. High-frequency torsional vibration is observed, with a magnitude of approximately 4500 rad/s2. The magnetometer-based rev/min is stable, although the periodicity is still close to 0.3 Hz.

It is clear that the RSS rev/min measurement cannot capture the rapid fluctuations in rev/min resulting from torsional vibration. The RSS stick/slip average measurement monitors changes in the existing RSS rev/min measurement; therefore, it is also unable to detect torsional vibration. The RSS whirl-average measurement, however, may be able to detect torsional vibration caused by the configuration of accelerometers used by the measurement. The RSS whirl measurement uses changes in centripetal accelerations to& detect BHA whirl. The whirl measurement reads moderate to severe, with periods of critical over this period.

Laboratory Tests

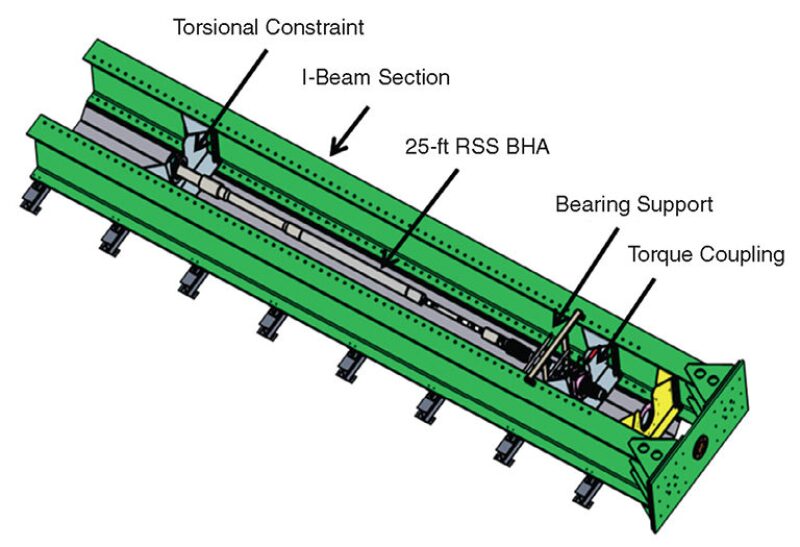

In order to gain insight into the downhole data and characterize the torsional response of the RSS, a laboratory test was commissioned. An RSS BHA approximately 25 ft long was placed into a purpose-built test rig. The entire RSS Triple Combo is approximately 100 ft long, and thus it was not feasible to test the entire system in the laboratory.

The test rig can be seen in Fig. 3 and consisted of two horizontal steel I-beam sections approximately 50 ft long. Carriages could be mounted at various positions along the I-beams and acted as BHA supports or mounts for motors or data-acquisition systems. For this particular test, the BHA was torsionally constrained at the uphole end by one of the carriages. The downhole carriage consisted of hydraulic rams and a quick-release torsional coupling. The BHA was centralized at the uphole end (at the torsional constraint) and at the downhole end between the bit and the RSS pivot stabilizer.

The test rig was configured to initiate a wide-spectrum torsional excitation into the BHA. The high-frequency content allowed the higher resonant modes of the assembly to be excited. The torsional excitation was such that resonances up to 100 Hz could be excited.

An accelerometer was mounted at the bit and oriented to measure tangential acceleration. The fast Fourier transformation of the accelerometer signal showed the natural frequency to be 69 Hz.

Discussion

The origin of the 0.3-Hz signal can be explained by use of the torsional-pendulum equation found in many reference sources. Calculations show that 0.3 Hz relates to the fundamental torsional natural frequency of the entire drillstring, from bit to surface. The low-frequency fluctuation in rev/min that was observed to fluctuate between zero and approximately 250 rev/min can best be described as modal-type stick/slip, if instantaneous pseudostick phases occur.

The high-frequency torsional oscillation experienced in field tests was also observed in the laboratory, with a much shorter section of RSS BHA. The same torsional-pendulum calculation used to justify the 0.3-Hz signal also can be used to explain the cause of the high-frequency oscillation.

The system response, in this particular field, is dominated by the drillstring fundamental torsional natural frequency, typically approximately 0.3 Hz, and the fundamental torsional natural frequency of the RSS, in this case 66 Hz. Conventional-type stick/slip is not observed in any of the DDS data records.

Findings suggest that the high-frequency, high-amplitude torsional vibration is attributed to a structural resonance within the BHA. Integration of the angular-acceleration signal suggests that the angular displacement resulting from excitation of the fundamental torsional mode of the BHA at 66 Hz at 10 000 rad/s2 creates a significant amount of shear strain in the BHA. At 66 cycles every second, it does not take long before fatigue failure becomes a serious issue. At this frequency, 1 million stress cycles occur in just 4.2 hours.

It is apparent that existing stick/slip and rev/min measurements are capable of detecting the presence of only the low-frequency rev/min oscillation (i.e., conventional stick/slip) and not high-frequency torsional resonance. The whirl measurement, on the other hand, detects the centripetal accelerations resulting from torsional vibration, and it may be possible to combine the stick/slip, whirl, and rev/min measurements, and some logic, to detect torsional vibration.

Application

The insensitivity of existing downhole measurements in detecting high-frequency phenomena would explain why the severe drilling conditions are not reliably indicated by the RSS stick/slip average measurement. A more-concise detection mechanism has been created to detect torsional resonance and other low-frequency torsional dynamics (and to warn of their occurrence). This new sensor is known as the RSS torsional dynamics indicator (TDI). It was discovered that sensors onboard the RSS, if reconfigured, could detect torsional resonance in real time.

A unique algorithm for determining the type and severity of downhole torsional dynamics has been incorporated into the TDI. A simple software update is all that is required to equip any RSS with this feature; no hardware changes are necessary.

The rev/min profiles for the various torsional dynamics were simulated, confirming that (a) the existing RSS rev/min and stick/slip average measurements could not detect rev/min changes attributed to high-frequency torsional vibration and that (b) the maximum instantaneous rev/min value encountered during torsional resonance was significantly higher than that portrayed by filtered magnetometer data.

This article, written by JPT Technology Editor Chris Carpenter, contains highlights of paper SPE 163428, “Torsional Resonance: An Understanding Based on Field and Laboratory Tests With Latest-Generation Point-the-Bit Rotary Steerable Systems,” L.A. Lines, SPE, D.R.H. Stroud, SPE, and V.A. Coveney, Weatherford, prepared for the 2013 SPE/IADC Drilling Conference and Exhibition, Amsterdam, 5–7 March. The paper has not been peer reviewed.