In the modern energy landscape, oil and gas companies are challenged to produce hydrocarbons more efficiently, safely, and sustainably than ever before. At the core of meeting these demands lies a strategic asset that continues to redefine the industry’s capabilities: data.

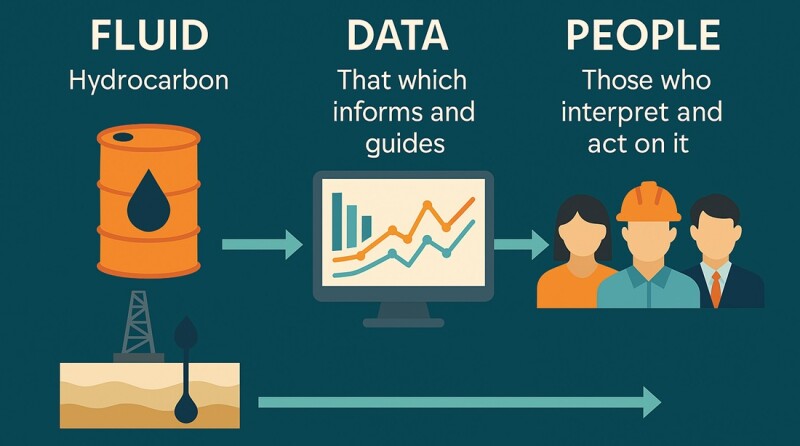

Globally, data is fundamentally acknowledged as the bedrock to every stage of the petroleum life cycle, from exploration and reservoir characterization to production optimization and abandonment. The full potential of data can only be realized, however, when it is viewed not in isolation but as part of the dynamic triad of the hydrocarbon resource itself, the data, and the people who interpret it and act on it.

A practical framework for data-driven value realization in the oil and gas industry is anchored on the following three key pillars:

- Hydrocarbons (HC)

- Data (D)

- People (P)

This HC/D/P framework explores how digital technologies are bridging these domains, improving performance, and unlocking new value, even in emerging areas such as carbon capture, use, and storage (CCUS).

Hydrocarbons—The Fluid of Interest

At the foundation of all petroleum activities lies the hydrocarbon resource. Whether crude oil, natural gas, or associated fluids, hydrocarbons remain the primary focus of operational and business strategy. Everything revolves around understanding the “where, how, and how much” of these resources—and doing so with increasing accuracy and precision.

From seismic imaging to core analysis and production logging, the objective is always the same: to characterize the subsurface as accurately as possible. But the hydrocarbon resource is only a part of the equation. The means by which they are discovered, produced, and managed depend greatly on data.

Data—The Informing and Guiding Element

Data acquisition is deeply embedded across oil and gas operations. Underscoring how prevalent it is, even when a well is shut in, data is continuously collected, whether it be pressure buildup trends, temperature variations, or fluid compositions. This data, when properly interpreted, becomes intelligence that guides operational decisions such as adjustments in production rates, intervention timing, equipment settings, flow assurance measures, and even strategic field-development planning.

For instance, downhole pressure changes and temperature data can signal a water breakthrough before it becomes critical. Scenarios involving a sudden increase in bottomhole flowing pressure and the different thermal signature of water as depth changes all speak to this fact.

Production trends can indicate the need for artificial lift optimization. Also, real-time drilling data can prevent costly kicks or stuck-pipe incidents. And historical well data supports accurate reserves estimation and field development planning.

According to a study by McKinsey, “on an oil rig that has 30,000 sensors, only 1% of the data are examined,” primarily because of poor integration, siloed systems, and lack of contextual analysis. Hence, the real challenge is not the availability of data but the usability. And this highlights the critical importance of turning raw data into structured insights through digital tools and analytics.

People—The Interpretive Resource

While data and hydrocarbons are the “what” and “why,” “people” is the answer to “how.” Engineers, geoscientists, operators, and analysts interpret and act on data, using it to make operational and strategic decisions. The quality of these decisions directly depends on the depth of understanding and contextual expertise applied to the data.

A single misinterpretation in accessory depth or formation pressure can lead to significant operational losses. Errors in subsurface modeling or fluid characterization can result in underperformance, costly workovers, or safety hazards.

Organizations that invest in cross-functional teams (CFTs) and data upskilling will achieve an increase in their asset performance. According to McKinsey, as reported by CIO Insight Hub, companies that adopt CFTs can see a 20–30% increase in productivity and a 15–20% reduction in costs. And in doing this, it becomes clear that technical capability, collaboration, and data literacy among personnel are as critical as the data itself.

The leads to the HC/D/P triad framework.

Digital Technology Developments, Bridging the Gap

Digitalization serves as the connective tissue among hydrocarbons, data, and people. It enables the flow of information across disciplines, reduces decision time, and facilitates predictive capabilities that can prevent issues before they occur.

Digital oilfield technologies, including advanced analytics, cloud computing, edge devices, machine learning, and digital twins, are being deployed across the exploration and production (E&P) value chain. These tools provide a unified view of the reservoir and operations, enabling faster and more informed decision-making.

Consider the instance of a real-time production monitoring system that combines live field data with reservoir models and engineering expert-driven algorithms. This real-time monitoring system allows engineers to track well performance, detect anomalies, and optimize flow rates. And these can be achieved remotely and in near real time.

Additionally, integrated platforms such as CypherCrescent’s SEPAL technology suite are redefining how teams interact with well and reservoir data. By automating workflows and simplifying complex interpretations, such tools empower multidisciplinary teams to make better decisions, faster.

Digitalization and CCUS

While originally developed around hydrocarbon production, the HC/D/P triad framework also finds relevance in CCUS, an area of increasing importance in the global push toward net-zero emissions. As it was with the hydrocarbon resource, success for the carbon system depends on

- The injected fluid (typically CO2)

- Subsurface data (e.g., injection pressure, plume migration, cap rock integrity)

- People (engineers, environmental scientists, regulatory stakeholders)

CCUS operations require high fidelity modeling of storage reservoirs, continuous monitoring of wellbore integrity, and compliance with environmental standards. Data is central to demonstrating containment, tracking CO2 plume behavior, and optimizing injection rates. And it is “people” who have been equipped with the right digital tools that will interpret this data to ensure operational and environmental success.

In this way, digital optimization frameworks originally built for oil and gas can be directly applied to CCUS projects. And this not only reinforces their value but also positions the oil and gas workforce to play a vital role in the energy transition.

Culture, Capability, and the Future Workforce

Digital transformation is not solely about technology; it is an integral of people and culture. Organizations that are succeeding in digital data integration are those that invest in talent development, foster a data-driven culture, and promote cross-disciplinary collaboration.

Equipping the next generation with the ability to contextualize and interpret data is fundamental to sustaining long-term performance. To this regard, knowledge transfer from senior engineers to younger professionals play a key role.

As industry increasingly embraces automation, artificial intelligence, and digital twins, human insight remains irreplaceable, particularly in complex, high-risk environments such as well interventions or brownfield asset optimization.

The goal is not to replace engineers with machines but to augment their capabilities.

Whether in traditional E&P operations or emerging domains such as CCUS, the ability to connect the fluid of interest with the insights from data, alongside expertise of the people, will determine the industry’s competitiveness and sustainability in the years to come.

Putting all these into context, the HC/D/P triad framework provides a strategic lens for understanding how value is created, where performance can be improved, and how innovation can be scaled. And this is empowered by the use of digital technology to drive energy innovation and sustainability.