This paper discusses the laboratory evaluation of potential high-pressure/high-temperature (HP/HT) drilling-fluid designs considered for a deep gas exploration well in Malaysia. Laboratory testing included evaluation of rheological properties, fluid loss, sag, and electrical stability, along with chemical analysis. Properties were measured before and after extended dynamic and static aging, up to the expected bottomhole temperature (BHT) and bottomhole pressure. Formulations were adjusted and retested until acceptable results were achieved.

Introduction

Proper drilling fluid is a critical component in safe drilling in HP/HT exploration. High subsurface pressures are controlled by the elevated density of the drilling fluid achieved through high concentrations of weighting agents. However, high-density muds often possess high rheological properties and, as a result, exhibit high equivalent circulating densities (ECDs), lost circulation, and low rates of penetration. Formulating thermally stable fluid for extreme high temperatures is a challenging task because conventional oil-based-mud additives thermally degrade at approximately 400°F. Nevertheless, maintaining constant fluid density in extreme borehole conditions is essential for well control.

Well Background and Drilling Objectives. The well was one of the first ultra-HP/HT exploratory wells planned for the South Malay basin. The objectives of the drilling-fluid design for this well were

- No nonproductive time associated with drilling mud

- Stable drilling fluid with low shear strength at static BHT (SBHT) for 16 and 48 hours

- Stable rheological properties at SBHT

- No excessive ECD associated with drilling fluid at bottomhole circulating temperature

- Controlled HP/HT fluid loss as per program and wellbore conditions

- Controlled salinity of water phase to balance formation

Drilling-Fluid Design for Ultra-HP/HT Deep Gas Well

The surface and upper-hole-section drilling-fluid plan for this well mainly consisted of high-viscosity sweeps of saltwater gel and potassium chloride water-based mud. Invert-emulsion drilling muds were used in the lower sections of the well.

Selection of Base Oil. Temperature and pressure negatively affect the rheological property of fluid, so the type of base oil used in mud formulations can be a key contributor to obtaining desirable rheological results downhole in ultra-HP/HT wells. For a list of physical properties and aromatics content of base oils commonly used in extreme HP/HT environments, please see Table 1 in the complete paper. Synthetic paraffin is noteworthy because of its relatively low density and kinematic viscosity. Furthermore, it has no aromatics content and has a high flash point. The low density and viscosity of synthetic paraffin are desirable because they can provide minimum plastic viscosity (PV) in the final mud formulation, resulting in low ECD and equivalent static density (ESD).

Evaluation of Drilling-Fluid Design. For a summary of target fluid properties by interval for the well, please see Table 2 of the complete paper. On the basis of temperature-gradient variation between intervals, two synthetic-based muds (SBMs) were proposed for the intermediate and final hole sections to minimize cost. The same synthetic-paraffin base oil was used for both SBM systems, thereby enabling a smooth transition from the one to the other without a requirement for a full displacement.

Multiple mud formulations were developed and evaluated in a series of tests to ensure thermal stability and desired fluid properties. The evaluation process began with testing of fluid properties before and after 16 hours of dynamic aging at BHT and after 48 hours of static aging. Fluids were then evaluated for stable rheological properties under HP/HT conditions as well as for static and dynamic sag properties. The best formulations were evaluated with state-of-the-art hydraulic-modeling software to estimate ECD/ESD and hole-cleaning efficiency. Adjustments were made to formulations that did not yield satisfactory results. The formulations were retested, and hydraulics modeling was repeated, until acceptable results were obtained.

The 12¼×17½- and 12¼×14¾-in. Sections. The wellbore temperatures for the 17½- and 14¾-in. sections were projected to be 240 and 280°F, respectively. Below 300°F, adequate rheological and filtration-control properties were obtained with conventional additives, and differences in density requirements between intervals were easily achieved by the addition of weighting material or unweighted premix, as needed. A 12-lbm/gal formulation for the 17½‑in. section was considered sufficiently nonchallenging, so only a 14‑lbm/gal formulation for the 14¾-in. interval was tested.

Rheological properties were measured at 120°F. HP/HT filtration tests were conducted at 250°F. Fig. 1 above presents the properties of the 14-lbm/gal SBM candidates in comparison with the target specifications. The blue bar indicates desirable fluid properties targeted for the interval. The PS1j system is the first formulation eliminated because it shows the highest 6-rev/min reading, resulting in a PV value greater than the desirable-PV range. Moreover, there is a substantial increase of gel strength between 10 seconds and 10 minutes, illustrating a tendency of the PS1j formulation to form progressive gel. The PS1i and PS1k formulations exhibit similar rheological properties. However, the PS1i system shows slightly lower HP/HT fluid loss. As a result, the PS1i design was clearly a leading candidate. To further confirm the stability of the design fluid formulation downhole, the PS1i system went through a sequential HP/HT rheology measurement by means of an HP/HT viscometer. HP/HT yield point (YP) and low shear-rate viscosity (6 rev/min reading) were used as indicators for stability of drilling fluid under wellbore conditions.

The 10⅝×12¼-in. Section. Unlike the previous sections, the 12¼-in. section was projected to be the HP/HT zone with a BHT and maximum wellbore pressure of 360°F and 9,144 psi, respectively. Most invert-emulsion-mud products do not tolerate this high-temperature environment. Several formulation strategies were investigated, including adjusting the OWRs, the additive chemical compositions and concentrations, and the alternative weighting materials. A dual-weighting-material approach was investigated as a strategy to achieve low rheological properties for high-density fluids.

All drilling-fluid formulations were prepared and then dynamically aged at 360°F for 16 hours. Simulated drilled solids were added to the formulations to emulate low-gravity solids (LGS). The weighting materials were a blend of 4.2 °API barite and manganese tetraoxide.

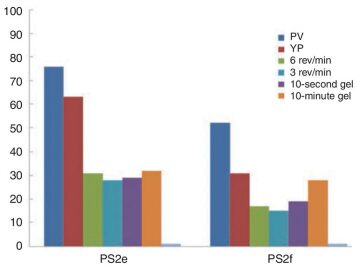

Fig. 2 summarizes key rheological properties of two formulations, PS2e vs. PS2f, after hot rolling at 360°F for 16 hours. The PS2f fluid exhibits more-desirable rheological characteristics (low PV and YP, constant viscosity at low shear rate, and lower gel strength) compared with the PS2e formulation. Because weighting material sag was a major concern for this fluid, viscometer sag shoe tests (VSSTs) were performed on the PS2f sample after hot rolling. A VSST is a quantitative method to determine weighting-material settling in a dynamic drilling fluid. The VSST of the PS2f sample yielded 0.19 lbm/gal, less than 0.5, which implies a small sag tendency. The good VSST result was accomplished with mixed weighting materials.

Usually, a substantial difference between circulating and downhole static temperatures exists for HP/HT zones. Extended operations downtime can expose the drilling fluid to high temperatures under static conditions. To address this concern, static aging tests were performed on the PS2f formulation to assess its stability under long-term static aging. Test results revealed that the PS2f sample after 16-hour dynamic aging yields favorably lower PV and YP values but exhibits slightly higher 6- and 3-rev/min readings compared with the target specification. The sample static aged for 48 hours demonstrated an increase in fluid viscosity; however, the fluid remained stable and showed good solids-suspension capability without a visual phase separation. Static sag testing reported a sag index of 0.529 and a shear strength of 284 lbf/100 ft2. This result suggests that the PS2f formulation maintains acceptable fluid rheological properties and good thermal stability with only a small barite-settling tendency, even during prolonged static aging.

The 8½×9½-in. Section. Drilling-mud design for the 9½-in. interval was the most challenging task in overall fluid planning. With an estimated BHT of 455°F and a bottomhole pressure of 13,683 psi at the projected vertical depth of 14,370 ft, this interval was considered the ultra-HP/HT tier. On the basis of the predicted density profile, the objective was to formulate the 18‑lbm/gal HP/HT SBM system with high-temperature fluid rheology and stability to 455°F.

Weighting materials used in these formulations were a blend of 4.2 °API barite and manganese tetraoxide. Simulated drilled solids were added to duplicate the effect of LGS on the formulations. All samples were prepared and dynamically aged at 455°F for 16 hours.

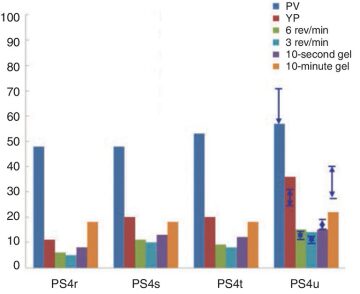

Fig. 3 displays the rheological properties at 150°F of the 18-lbm/gal SBM sample after 16 hours of dynamic aging at 455°F. The blue bar represents the desirable fluid range for this hole section. All four formulations meet the target PV value of less than 70 cp. The PS4u fluid exhibits the highest PV and YP values and relatively higher shear-rate properties, but HP/HT filtration tests revealed that it has the lowest fluid loss compared with the others (5.8 cm3/30 min vs. ≥7.4 cm3/30 min). The high viscosity of the PS4u fluid is a result of the addition of high-temperature polymeric filtration-control additives that were added to reduce fluid loss at 455°F. Along with having the high PV value, the PS4u fluid has the highest YP value of 79 lbf/100 ft2 at 455°F and 12,000 psi after 48 hours of static aging. The PS4u system still shows relatively high PV values compared with the other fluids, although the sag index (0.515) of the PS4u sample is good. Additional adjustments are needed for the PS4u formulation.

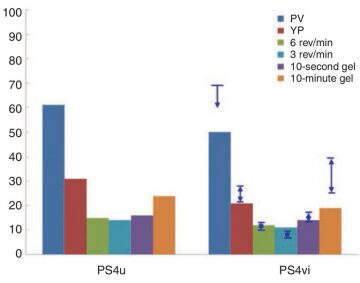

Because high-temperature polymeric filtration-control additives are the main contributors to high PV and YP values, a decrease in their concentrations should lead to lower PV and YP values. Two fluids were prepared and dynamically aged at 455°F for 16 hours. Fig. 4 shows fluid rheological properties measured at 150°F after hot rolling. The blue bar represents the target fluid specification for the 9½-in. section. The PS4vi formulation meets all specifications for the 9½-in. hole except for the 10-minute gel strength. Compared with the PS4u formulation, the PS4vi formulation exhibits lower PV and YP values and lower low-shear-rate viscosity, while fluid loss is similar (6.4 cm3/30 min for the PS4vi and 5.8 cm3/30 min for PS4u at 350°F). The VSST result for the PS4vi sample after hot rolling for 16 hours was 0.09 lbm/gal. Results indicate that the fine-tuned formulation (PS4vi) shows relatively low YP values across a range of temperatures and pressures (455°F and 12,000 psi).

It was expected that the 18-lbm/gal drilling mud would stay downhole under static condition for approximately 4 days of logging. Therefore, the fine-tuned PS4vi system underwent 96 hours of static aging. The PS4vi fluid remained stable, with an electrical stability of 1,284 V, acceptable PV and YP values, and acceptable low-shear-rate viscosities after long-term static conditioning. HP/HT filtration tests were conducted on the 96‑hour statically aged sample. The fluid loss for this formulation was 9.2 cm3/30 min at 350°F. Finally, static sag testing for 96 hours produced a sag index of 0.519, with 3% free oil.

This article, written by Special Publications Editor Adam Wilson, contains highlights of paper OTC 24830, “Ultra-HP/HT Drilling-Fluid Design for Frontier Deep Gas Exploration in South Malay Basin,” by Anuradee Witthayapanyanon, SPE, Kathi Chandramouleeswaran, Ahmad Bin Dollah, SPE, Dennis Clapper, SPE, Ronald Bland, SPE, and Akachai Kongsawast, SPE, Baker Hughes; and Michael Pepple, SPE, Khairul Anwar Nasrudin, SPE, and M. Abshar, SPE, Petronas, prepared for the 2014 Offshore Technology Conference Asia, Kuala Lumpur, 25–28 March. The paper has not been peer reviewed. Copyright 2014 Offshore Technology Conference. Reproduced by permission.