Drought conditions rated as “moderate or worse” affected 31 US states as of 8 June, as reported by the US National Integrated Drought Information System. Particularly dry are the West and Upper Midwest regions, relevant to the Permian and Bakken, respectively.

While not a record-level drought, attention is turning to the Missouri River in North Dakota where streamflow levels are at low levels for this time of year—about 48% below the seasonal average. About 96% of the water in North Dakota’s rivers and streams flows through it, making it one of the main sources of fresh water for oil and gas production in the Bakken. In the extreme drought, water restrictions could come into play.

Throughout the industry, recycling and reuse of frac and produced water have been studied, and where the chemical makeup of the frac or produced water is suitable for optimal and economical treatment, it has been implemented.

However, Bakken production is typically associated with 1.0 to 1.5 bbl of produced water per barrel of oil (a water cut of approximately 50% ). It is highly saline with total dissolved solids (TDS) ranging up to 350,000 mg/L (seawater is about 35,000, or 10 times less salty than Bakken brine). Treatment options for such high TDS levels are limited and often cost-prohibitive.

The Bakken’s produced water volumes increased fourfold since 2008 to about 740 million bbl per year due to increasing volumes per well and increasing water cut. Produced water disposal volumes in the same period increased fivefold to about 680 million bbl per year. More than 95% of saltwater disposal (SWD) targets the Inyan Kara Formation, the lowermost sandstone interval of the Dakota Group.

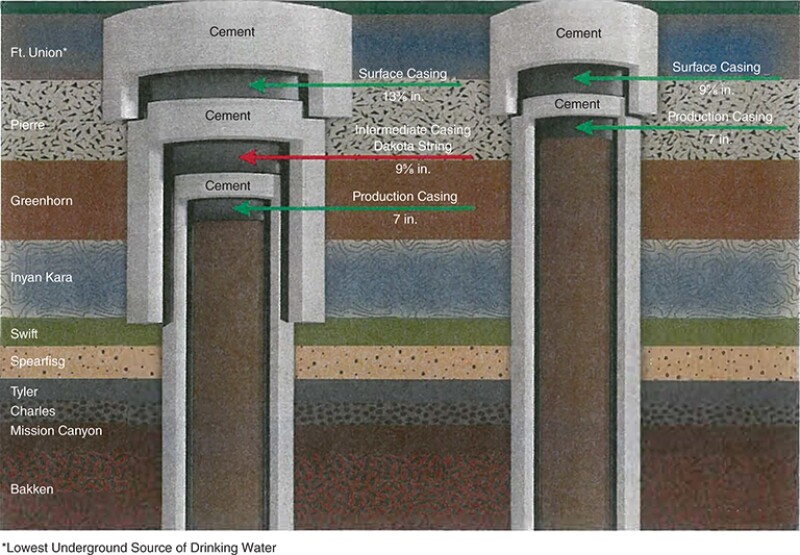

The increase in SWD volumes has resulted in localized areas of high pressure in the formation in geographic regions associated with high levels of oil and gas activity. This increased pressure affects the economics and risk associated with the drilling of new wells that now require additional intermediate casing strings (“Dakota Strings”), adding a cost of $300,000 to $700,000 per well. About 200 wells to date have been identified with additional casing strings, according to the Energy & Environmental Research Center (EERC).

Faced with the challenges of high salinity in recycling/reuse of produced water, constraints on SWD injection, freshwater limitations, pressure regulation, and inflated drilling costs, a 2-year project was begun in January 2020 which may hold promise for greater use of the produced water. Participants in the $1.3-million project are EERC, Nuverra Environmental Solutions, and the US Department of Energy.

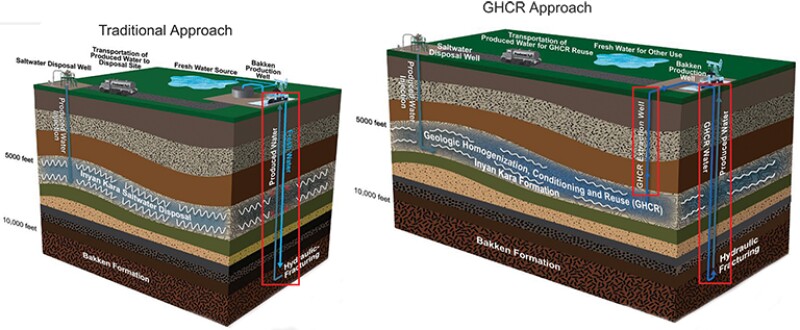

The Geologic Homogenization, Conditioning, and Reuse (GHCR) project uses the Inyan Kara Formation as a natural medium for managing produced water recycling and reuse. The concept aims to take advantage of the hypothesized natural processes occurring in the subsurface (e.g., filtering, mixing, diluting, etc.) and then extract the water at some distance from the disposal well. The extracted water, presumed to be lower in TDS than the injected produced water, may be more suitable for use in hydraulic fracturing makeup water or for subsequent treatment.

If the theory is correct, demand for fresh water will be decreased and the extraction of water from the formation will slow the pressurization of SWD targets, extending the life of disposal wells and reducing the need for additional disposal wells in the future.

Deployed at scale, GHCR could provide a solution to the Inyan Kara pressurization, which if it continues could increase drilling and disposal costs by $1.5 to $10 billion (if 20% of the projected remaining Bakken development were to be affected by the formation’s pressurization).

A draft final report is planned for 30 November 2021.

For Further Reading

Produced Water Management and Recycling Options In North Dakota. Energy & Environmental Research Center.

Will Water Issues Constrain Oil and Gas Production in the United States? Environ. Sci. Technol. 2020. B. Scanlon, UT Bureau of Economic Geology, et al.