Pumps are not living creatures, but with progressing cavity pumps (PCP) that can be a useful metaphor.

A case in point was a talk listing mistakes that “can doom a PCP to early failure” by Shauna Noonan, a former SPE president, currently a fellow and senior director at Occidental Resources and that day at the SPE Artificial Lift Conference, an engineer with 25 years of PCP experience.

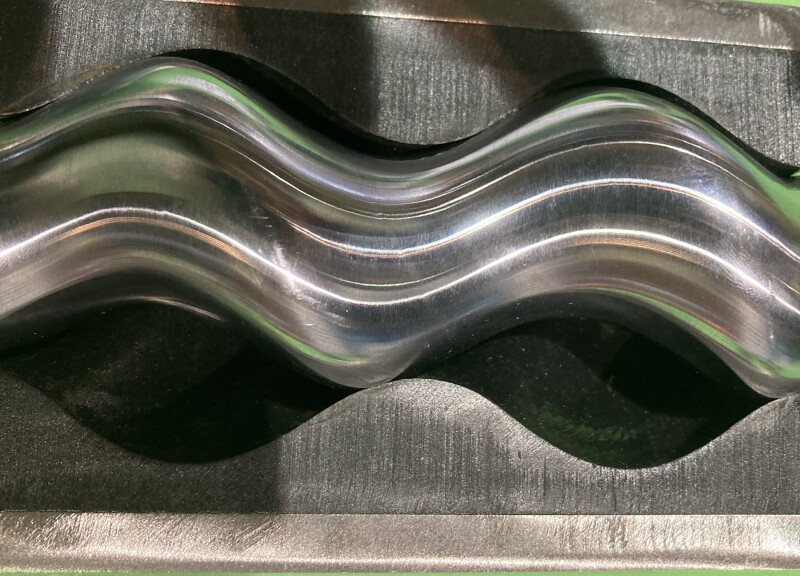

The anthropomorphic descriptions are a product of the interactions within a PCP between the rotor—which moves multiphase fluids through helical cavities in the stator, which is typically comprised of an elastomer surrounding it.

The dimensions of the elastomeric stator change when the rotor begins rotating, increasing the differential pressure inside the pump and adding heat to the elastomer, causing the elastomer to swell and narrowing the tolerances between the rotor and stator. Note that there can be cases where the elastomer shrinks instead of swelling.

“The tolerance between rotor and stator is dynamic. The elastomer is a living, breathing element,” Noonan said.

The list of life-extending tips keeps coming back to understanding how changes to operating conditions, downhole fluids, and reservoir pressures can affect the PCP pump.

Noonan offered a sneak peek at results from a field in the Middle East where PCP run lives were doubled over a 4-year period by simply understanding PCP fundamentals and applying operating and pump selection criteria. The paper, SPE 206909, will be presented at the SPE Middle East Artificial Lift Conference and Exhibition in late October.

The thinking required to improved PCP performance is often counterintuitive. For these pumps, loose is better than tight and not targeting 100% volumetric efficiency downhole is the better long-term bet.

In order to account for the swell that the elastomer will see due to reservoir fluids and temperature, the acceptance pump efficiency from the bench test should not be any higher than 80% at the differential pressure that will be needed from the pump. This is only for low-viscosity fluids. For high-viscosity fluids, the acceptance criteria could be as low as 0% efficiency.

“The tighter it is, the hotter the elastomer will get and put it beyond its temperature rating,” Noonan said.

Looser Is Better

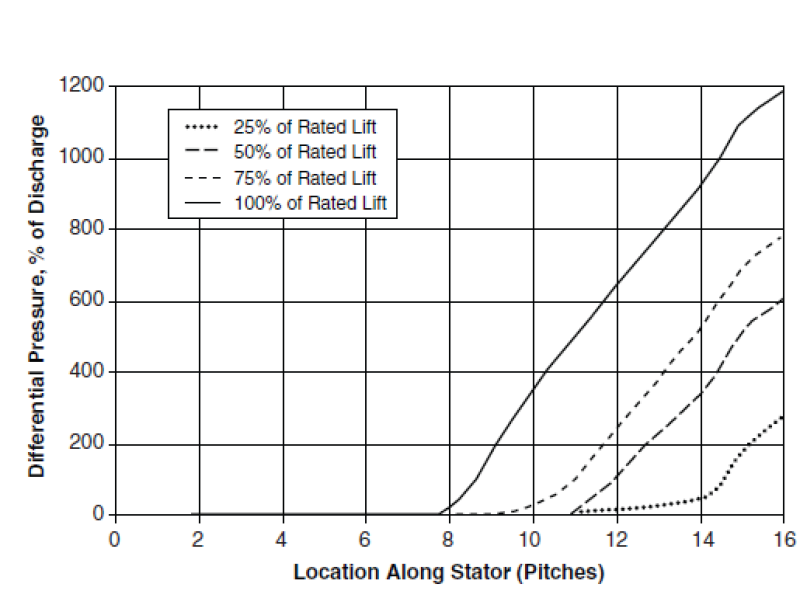

To better understand why that is the case, Noonan strongly recommended a paper by Evan Noble and Lonnie Dunn based on testing at Weatherford. The results showed many instances where the differential pressure across the pump was concentrated towards the discharge, rather than evenly spread over its length (SPE 153944).

The study showed why PCP pump failures often occur at the upper portion of the pump. It included a chart showing the importance of fluid slippage to distribute the differential pressure across the pump. The slippage is highest at 100% lift capacity.

Noonan talked about a field in Canada where the PCPs were failing early at the upper portion of the pump, and since the reservoir pressure had increased due to a waterflood, the differential pressure needed from the pumps was less. This chart demonstrates what occurred in the pumps and that the differential pressure had concentrated much closer to the discharge leading to elastomer failure.

The differential pressure curves will vary depending on the pump design (rotor/stator interference fit), operating speed, presence of free gas, and fluid viscosity. While the specifications can allow an expert an educated performance prediction, bench testing is needed to catch manufacturing defects and collect data needed to predict the interference fit between the rotor and elastomer once in the wellbore.

Those tests need to be run at rates that will typically be seen in operation.

“At the average rpm it will operate, and at the differential pressure needed for most conventional applications, you will not accept a pump with a higher than 80% volumetric efficiency,” Noonan said. It is also important to look at the trends of efficiency and torque for all the tests as they also could provide valuable information during the pump acceptance process.

Differences in the composition of the fluids can have a major impact on the operating life. She described a situation where an African operator knew the pumps would be exposed to diesel used in the completion fluid, and elastomer compatibility tests with diesel were completed to understand the amount of swell. The problem was that the diesel used in the tests was a different blend than that used by the operator and upon installation the elastomers swelled so much that the rotors could not rotate.

Those in charge of managing the pumps need to be aware of the impact that operational changes can have throughout the entire time the pump is in the well. Given all the variables. the right answer may be a range rather than a precise value and be subject to change.

“Err on the side of being too loose. You can put in a larger rotor later if that fit proves to be a problem,” she said.

Ultimately the PCP will depend on a human’s willingness to learn how it is likely to perform in the ground.

“Establishing the correct bench test acceptance criteria and operating guidelines is key to reducing premature failures and extending the overall life of the PCP,” Noonan said.

Building in a Leak

The search for the correct sort of looseness lead PCM Artificial Lift Solutions, which presented a paper highlighting the extended lifespan of pumps using rotors built to engineer it in.

These oval-shaped flat spots machined into the rotor, called hydraulic regulators, are designed to avoid the concentration of pressure and stress at the end of the pump by providing a “controlled leak path,” said Paul Skoczylas, a product champion of PCM, who presented paper SPE 209764.

This is the latest in a series of performance reports on a design that has been around for more than a decade. Initially, they drilled holes in the rotors to create leak paths. Later they switched to milling the regulators to avoid the weak spots associated with the holes.

The recent technical paper offered updated information on the durability of the design when dealing with challenging conditions.

In heavy-oil wells in Colombia, PCM reported that the design extended the average life of pumps from 212 days, from a high of 532 days to 420 days and still running.

Pumps removing water from coal-seam gas wells in Australia, where high gas levels and clay solids are threats, it reported the design extended the average lifespan from 738 days for average PCPs to more than 1,800 days.

This design may allow operators to run the pumps at more than 80% of the rated capacity, but Skoczylas added that it will vary depending on the conditions.

While he acknowledged that adding hydraulic regulators does reduce the torque a bit, they have not gotten any complaints about that.

It is not the newest technology on the market but in the oil business that can be a good thing.

They have a decade’s worth of experience to offer and “the cost of this pumps has come way down ... over the last 10 years,” he said.