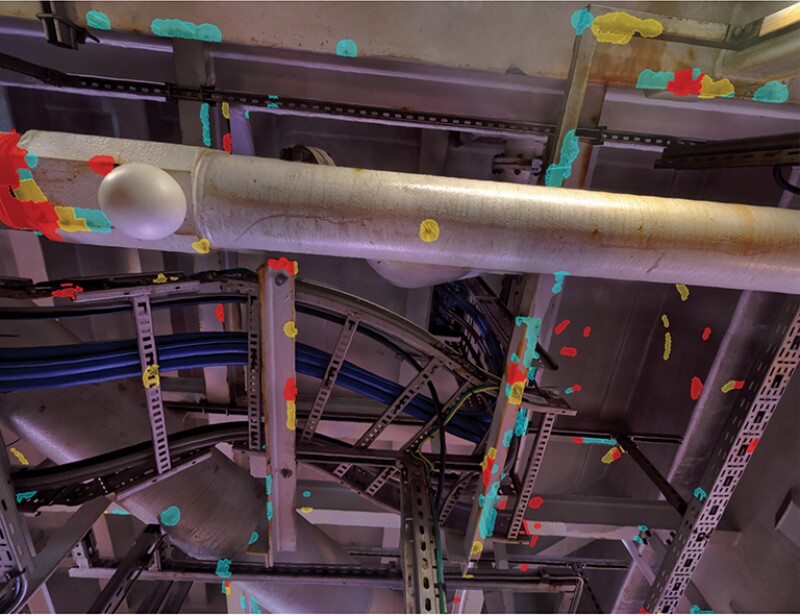

The complete paper discusses risk reduction and increased fabric-maintenance (FM) efficiency using artificial-intelligence (AI) and machine-learning (ML) algorithms to analyze full-facility imagery for atmospheric corrosion detection and classification. With this tool, a comprehensive and objective analysis of a facility’s health is achievable in a matter of weeks from the time of data collection. This application of AI and ML is a novel approach aimed at gaining a comprehensive understanding of facility-coating integrity and external corrosion threats.

Introduction

Atmospheric corrosion is the most-significant asset-integrity threat in the Gulf of Mexico (GOM). Offshore facilities require constant inspection and FM—and the significant financial obligation of these activities—to stay ahead of rapid equipment degradation.

In general, regulatory codes in the GOM require a visual inspection of pressure equipment and piping on a 5-year frequency at minimum. A common approach is to inspect 20% of the facility per year, with a rolling 5-year inspection plan, to balance the inspection work through time.