The offshore oil and gas industry has spent the past several decades focused on developing innovations that allowed it to move into deeper and increasingly harsh environments.

This pursuit remains central to the cause, but the business now has a new set of advancements it must also champion: low-carbon and emissions-reduction technology.

At this month’s Offshore Technology Conference (OTC) in Houston, upstream engineers from across the globe showcased their latest work on this expanding front in a number of new technical papers.

“The ongoing paradigm shift towards energy transition and decarbonization, while challenging, simultaneously unveils avenues for creative ingenuity,” wrote authors from Brazil’s Petrobras in OTC 35167. “This transition is a fertile ground for the genesis and implementation of innovative technologies, encompassing carbon capture and storage, the integration of renewable energies, and the advancement of monitoring systems.”

Petrobras’ authors outlined a vision for a low-carbon, ultradeepwater project that utilizes all-electric subsea production systems and autonomous inspection robots. Such a project might also feature long-distance tiebacks to shore-based or shallow-water facilities, and long-distance transmission lines connected to Brazil’s renewable energy grid à la Equinor’s shore-to-sea electrification scheme in Norway.

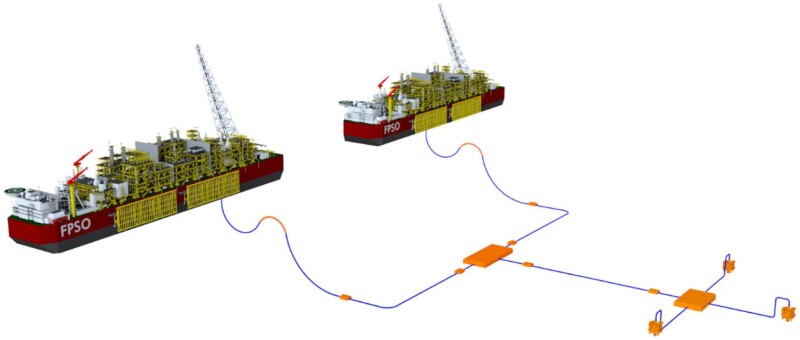

Additionally, OTC 35167 proposes the deployment of floating production, storage, and offloading (FPSO) units that are “engineered for net-zero emissions.”

Petrobras is not alone in exploring ways to decarbonize FPSOs, which generate the majority of their emissions through their power plants.

ExxonMobil and Saipem presented a joint study that explores carbon capture and storage (CCS) concepts from FPSOs using subsea pipelines to transport the CO2 to a separate storage location.

Their paper, OTC 35195, claims that while there are no “significant showstoppers” to FPSO-based CCS, there do remain several challenges that various industry groups must keep working on to overcome.

High on the list are flow assurance and corrosion issues because CO2 flow streams are highly influenced by the presence of even small amounts of impurities, such as sulfur oxides and nitrogen oxides.

OTC 35195 also highlights that there are as of yet no industry standards for the maximum allowable level of impurities for pipeline transportation of dense phase CO2.

This represents a critical technical gap to fill since, as the ExxonMobil and Saipem authors note, even trace amounts of water in a CO2 stream can react with various impurities to form a range of corrosive acids. They further pointed out that commercial simulators fail to accurately represent the thermodynamic effects of different CO2 mixtures due to a lack of experimental data.

One of the world’s biggest FPSO builders, SBM Offshore, has also weighed in on the topic in its own paper. In OTC 35142, the company’s authors found there are a number of potential challenges that include ensuring enough heat and electricity are available to run the capture technologies.

But like those within ExxonMobil and Saipem, SBM’s experts believe combining CCS with FPSO is still technically feasible.

Their study looked at using long-established amine contactor tower technology along with the “marinization” of other capturing components that have been used primarily in stable onshore environments. SBM found that capturing units might be as much as 30-m longer than a typical FPSO hull design to account for the additional weight.

The SBM assessment also determined that the capture benchmark for FPSOs should be at least 70% in most cases, as this figure corresponds to the typical proportion of CO2-equivalent emissions from the gas-fired turbines used for power generation. Capturing from the turbines' flue gas streams would result in an estimated reduction of 300–1,300 tons of CO2 per day for FPSOs with processing capacities ranging from 100,000 to 232,000 B/D.

While carbon capture is a long-established practice offshore, it has involved capturing CO2 from produced oil and gas streams which is far different from capturing post-combustion CO2. As SBM highlights, offshore Brazil features some gas fields with a CO2 content as high as 60%, in stark contrast to the concentrations of 3–4% CO2 typically found in flue gas.

As some companies continue to mull over low-carbon FPSO designs, Equinor is poised to become a first mover in this area.

At the conference, the Norwegian operator presented OTC 35216 which details its latest FPSO that is destined for the Raia gas and condensate project off the coast of Brazil. First steel was cut this March at a shipyard in Brazil for the FPSO which will be able to process 126,000 B/D of oil and 16 million m3/D of natural gas.

Scheduled to begin production by 2028, the $9-billion Raia development will be Brazil’s largest gas project and is expected to account for 15% of the country’s domestic gas supply.

Equinor has boasted that the Raia FPSO being built by MODEC will be the most carbon-efficient in the world, achieving a CO2 intensity of less than 6 kg/BOE—about a third of the global average.

Equinor’s expectations are backed by several key design choices, chief among them is the selection of a combined-cycle gas turbine (CCGT) to power the FPSO. This marks the company's second selection of a CCGT power plant, following the Bacalhau FPSO, which was deployed offshore Brazil in 2023 and is expected to begin production later this year.

Baker Hughes, the manufacturer of the CCGT technology that utilizes a steam turbine to harness waste heat, has said these units can reduce carbon emissions by 20% compared to FPSOs powered by open-cycle gas turbines.

Another departure from the status quo is Equnior’s decision to process the sales gas offshore instead of at an onshore site. The operator believes that this approach will contribute to an additional 11% reduction in emissions compared with typical FPSOs.

Other mitigation measures on the Raia FPSO include closed flares, variable speed drives for gas compressors, and a four-stage oil/water separator instead of the traditional three-stage system.

Equinor said its next set of goals involve lowering the topside emissions by capitalizing on operational improvements. The company added that gains from data analytics and predictive maintenance strategies have not yet been factored into the project assumptions, thus offering the potential to drive further energy and fuel efficiencies.

For Further Reading

OTC 35216 An Innovative and Low-Carbon Approach to the Development of Brazil's Largest Gas Project by S. Ballesteros and S. Seljebø, Equinor.

OTC 35142 Carbon Capture on FPSOs by L. Le Touzé, F. Fourrier, and R. Berendsen, SBM Offshore; and S. Yamamoto, T. Kamijo, and Y. Tanaka, Mitsubishi Heavy Industry Ltd.

OTC 35167 How Technology-Based (Disruptive) Production Concepts May Become a Game Changer in Ultradeep Water Oil and Gas Production To Guarantee Energy Security and Reduce Greenhouse Gas Emissions by F.M. Passarelli, F.D. Castro, A. Costa, and L.D. Andrade, Petrobras/CENPES; A.R. Santos, V.L. Matos, and M. Roberto, Petrobras/SUB; and A.M. Bidart, Petrobras/LIBRA.

OTC 35195 The Journey of CO2 From the Capture to the Subsea Sequestration by G. Arcangeletti, A. Di Felice, D. Borghi, and F. Castiglioni, Saipem; J. Ma, R. Luft, and W. Sun, ExxonMobil.