Throughout Earth’s history, powerful geological processes have shaped the planet, formed diverse landscapes, and hidden valuable resources. Like silent architects, these processes play a crucial role in creating the world we see today.

One important aspect of this geological story is the formation of critical minerals—essential elements for modern technology. These minerals are not random features but are closely tied to the larger narrative of Earth’s evolution.

Scientists and engineers are exploring the connections between geological processes and the creation of critical mineral deposits to understand better how to identify, extract, and produce these deposits to help meet the demand for resources considered the building blocks of an electrified future.

Used in various applications, from energy production and national defense to transportation and communication technologies (think batteries for electric vehicles, permanent magnets for wind turbine generators), critical minerals are defined as non-fuel minerals or mineral materials essential to economic or national security and have a supply chain vulnerable to disruption.

The International Energy Agency (IEA), in its latest Critical Minerals Market Review, reported that the record deployment of clean energy technologies has propelled the huge demand for critical minerals such as lithium, cobalt, nickel, and copper.

“From 2017 to 2022, the energy sector was the main factor behind a tripling in overall demand for lithium, a 70% jump in demand for cobalt, and a 40% rise in demand for nickel,” the report said. “The market for energy transition minerals reached $320 billion in 2022 and is set for continued rapid growth, moving it increasingly to center stage for the global mining industry.”

In the US, critical mineral supply chains are heavily dependent on imports. In 2021, the US was 100% import-reliant for 14 of the 50 critical minerals identified by the US Geological Survey (USGS) in 2022. Additionally, according to the USGS, most of the critical minerals that are essential for meeting decarbonization goals have a net import reliance of greater than 50%.

Securing Supply of Rare Earth Elements

Critical minerals categorized as rare earth elements (REE) are particularly important to reaching decarbonization goals. With a name reminiscent of science fiction superheroes, the lanthanides are a series of 15 elements—plus scandium and yttrium—collectively regarded as REE. REEs range from light (LREE) to heavy (HREE). While not geologically rare, extraction and processing are complex, expensive, and environmentally hazardous.

In addition to being a leading source of critical minerals gallium, germanium, and graphite, China dominates REE production and processing. According to a report by The Oxford Institute for Energy Studies, the country is home to some of the most productive and lowest-cost REE-containing geological formations, which the government has been developing since the 1970s. China holds 37% of the world’s REE reserves, as compared to the US, which held only 1% of the reserves in 2019.

US critical mineral supply chains have the potential to be disrupted by adverse foreign actions, pandemics, natural disasters, and other global events. For this reason, developing domestic resources to secure supply chains and meet future critical mineral demand has become a national priority, with the signing of Executive Order No. 14017 by US President Joe Biden in February 2021.

On the Hunt

However, before domestic supply chains can be secure, there must first be a steady supply of REEs and critical minerals. Currently, the only US rare earth materials production source is in Mountain Pass, California. New domestic locations to extract critical minerals must be found to meet the expected increase in demand.

Researchers at the US Department of Energy’s National Energy Technology Laboratory (NETL) used data and artificial intelligence to develop a new geologic resource assessment model that, when tested at a coal mine in Wyoming’s Powder River Basin, revealed the largest unconventional deposit of magnetic REEs discovered in the US. The mining company, Ramaco Resources, reported to the US Securities Exchange Commission in October that the estimated resource size of the overall total rare earth oxides is about 1.2 million tons.

Kelly Rose, Burt Thomas, and Scott Montross are part of the NETL research team that helped unearth the potential presence of REEs at Ramaco’s Brook Mine, located about 7 miles north of Sheridan, Wyoming, using the Unconventional Rare Earth Element and Critical Minerals Assessment (URC) method they helped to develop.

Unconventional critical mineral resources and rare earths refer to any resource from a geologic or secondary byproduct host that is distinctive from the mechanisms resulting in conventional, established deposits.

“Various critical minerals and rare earth resources are considered conventional as they’ve been in production for many decades. While the US does have conventional resources, they have not largely been found here,” said Rose, a research geologist and senior fellow at NETL.

“They’re more common in parts of Africa, Australia, Southeast Asia, and South America. As a result, the world market depends on those more established resources,” she noted, adding that these resources are largely tied to what she identified as specific geologic parameters in igneous or metamorphic settings.

“These conventional critical mineral resources are established, and the mechanisms by which the rarest critical minerals show up in those deposits have been documented, described, and are the focus of extraction efforts to support global purposes,” said Rose.

She added that the team was tasked 8 years ago with looking for “nontraditional sources of critical minerals.”

The sources were identified by published studies documenting geologic characteristics that resulted in the accumulation of rare earth and critical minerals in nontraditional media, she said.

Rose added, “These individual studies showed the potential for these types of critical mineral deposits in association with sedimentary systems which often coincide with oil, gas, and coal systems, but not because of the oil, gas, and coal. But like prospecting for oil, gas, or other mineral resources, these critical minerals still require the right geological ingredients to stack up in those systems to find a viable accumulation.”

Sourced from in-situ geologic deposits or from secondary byproducts of anthropogenic processes, unconventional critical mineral resources require revised or new methods and models to characterize and predict locations that have the right combination of unique source and temporal controls resulting in these deposits.

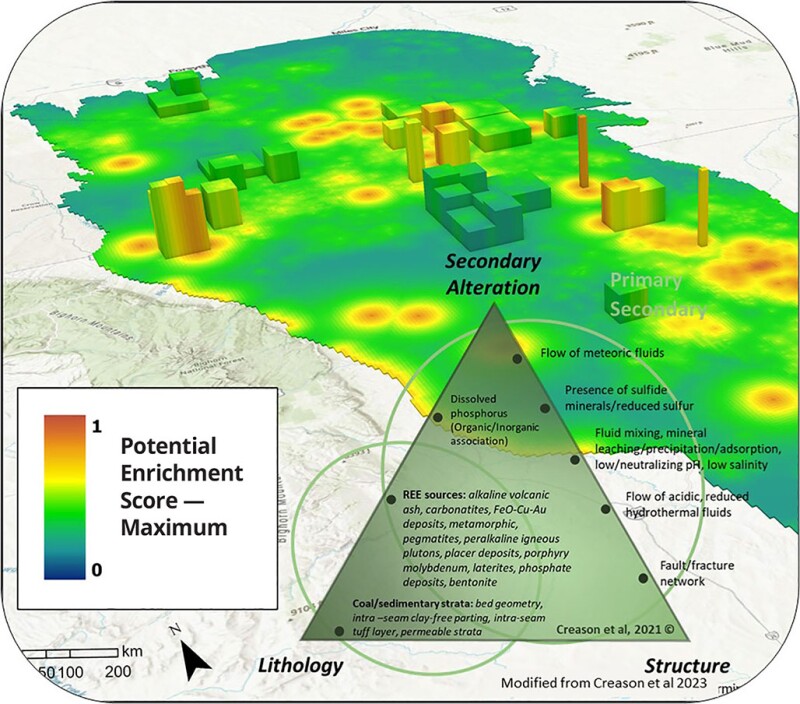

Rose described the team’s work as understanding how the mineral enrichment of the geologic “containers” where these critical minerals are found developed into their current state by “looking at it through the lens of specific lithologic, structural, and alteration criteria. Where these key criteria coalesce, it indicates if there’s a likelihood of concentration of unconventional critical minerals.” These criteria were used to develop a geo‑data science and artificial intelligence prospect forecasting model for unconventional critical minerals.

Montross, a research geologist and critical mineral technology manager at NETL, noted that the idea to look for these resources “kicked off with the idea that coal or coalbeds were the places these types of enrichment occurred, but it was by looking at different types of rocks, like shale and sandstone, we also saw redistribution and accumulation of the critical minerals.”

Key to the model presented in a paper coauthored by Montross, Rose, and others is understanding the different types of enrichment mechanisms and having the data that supports how it occurred, explained Thomas, the technical portfolio lead for NETL’s critical minerals group.

“The model asks three questions: does the data exist, and does the data support any one of the enrichment mechanisms? It then asks if the data exists spatially to determine the probability of specific enrichment mechanisms occurring in an area. The model creates what we call a prospectivity map, and it was a subset of one of these maps that led us to Ramaco’s Brook Mine,” said Thomas.

The team used the Powder River Basin as a test region for the model and its forecasts. To help validate the results, the team needed direct measurements from field samples of critical mineral concentrations and types.

In addition to previously published data, the team received new samples from the Brook Mine to assist with this effort. Recovering a 200-ft-long continuous core from the Brook Mine with every type of rock representative of the Powder River Basin helped confirm the presence of the critical minerals and REE, according to Montross.

“With the core analysis we did at NETL, we started to identify those original mechanisms were not occurring just in the coalbed, but were likely happening in the other layers, as well,” he said.

As an unconventional resource, the Brook Mine comprises more than 15,800 acres outside of Sheridan. It is one of the largest privately controlled mineral reserves in the western US, according to Ramaco. The NETL team discussed with the company in 2021 the opportunity to obtain validation data and help demonstrate the URC model as a test case. Roughly 4,500 acres were permitted for mining in 2020, which is where the initial exploration and assessment program was conducted.

“We requested samples and then ground them up for analysis to test the model,” said Thomas. “As we learn more about these unconventional deposits, the science that goes into that model will ultimately change as we continue to learn about new types of enrichment mechanisms where we might learn details about the data that would support those enrichment mechanisms.”

He added that the model’s ability to “identify these mineral resources that no one before has on their books” excites him about the project. “We’re identifying the value of minerals buried in the ground that no one has yet recognized as an asset for the country,” he said.

The Brook Mine ranks among the highest relative concentrations of magnetic REEs yet discovered, including HREEs terbium and dysprosium, as well as LREEs neodymium and praseodymium. Initial estimates are that approximately 28% of deposit concentrations may be in the form of magnetic REEs, according to Ramaco. The test results were confirmed by independent mining engineers at Weir International.

Ramaco said that developmental mining at the Brook Mine began in October. The additional 11,300 acres will also be assessed and could provide opportunities to increase the scale of overall development in the future.

Help Wanted

Finding these deposits is a significant first step on a long journey that includes developing extraction and production methods that are scalable, economical, efficient, and sustainable. All are processes in which the petroleum industry has deep knowledge and expertise.

The increasing demand for critical minerals creates collaboration and technology transfer opportunities between the petroleum and mining industries. It also enables the development of new resource evaluation, extraction, and refinement methods, making it possible to derive new value from existing oil and gas wells or coal mines.

The URC model applies to many geological environments, but it is also a starting point, according to Rose.

“With the current state of knowledge of the basic science of the geology that controls how and where these resources are known to occur, the model uses a combination of geoscience systems expertise with artificial intelligence methods to provide a systematic resource predictive modeling approach. This approach can benefit from the petroleum and mining industry’s expertise in subsurface modeling as well,” she said.

Further refining and improving the model requires data, which is something the petroleum industry has ample amounts of stored in enough data lakes to create data oceans. But much of industry’s data are behind lock and key, making it unavailable at present, for large scale, AI-informed efforts like this.

“The petroleum industry is restrictive about what they share,” said Rose. “But there are new ways to protect data and a growing recognition that data-driven AI models benefit from larger scales of data inputs. So perhaps there is potential for coordination to help accelerate further maturation of this type of modeling that also can benefit the public, energy communities, and the commercial sector as we all work to unlock clean energy opportunities.”

One of the strengths of the URC assessment model and method is that because it utilizes artificial intelligence, it does not look at one leasehold in the puzzle.

“The URC model uses large AI modeling to improve local forecasts and details, even where data may be scarce or unavailable. It looks at the big picture to improve predictions for specific locations,” said Rose.

She added that the data doesn’t have to be specific to rare earths or critical minerals. “Actually, most of the data that are out there today aren’t tied to the explicit direct measurements of critical minerals. We need more of that data for validation and for improving models, but the URC method, like many resource assessment methods, relies on data about the systems that lead to accumulations, indirect measurements that add up to insights and the ability to systematically predict likelihood of an accumulation,” she said.

“The mining sector’s engagement in sharing data was one of the reasons that this project could progress so quickly.”

Like the unconventional oil and gas resources that NETL helped to unlock through its Eastern Gas Shales Project, similar challenges exist in unlocking the potential of unconventional critical minerals and REEs.

“Just like with the unconventional oil and gas space decades ago, the unconventional critical minerals space is one where we have not yet developed the technologies for extraction and recovery,” said Thomas. “To move forward with this, we do not necessarily know the economics or the extraction potential. This is what is keeping the project moving forward.

“In the old days, we found oil and gas deposits in specific locations. With the right technology, the unconventional oil and gas revolution made it possible to literally drill anywhere without missing,” Thomas said. “Our ability to drill down and then laterally made it possible to target a specific narrow resource in the sediments. As we think in the long term, how will we get these critical minerals out of the ground?”

The goal for the petroleum and mining industries is the same at the end of the day: extract resources from the Earth’s subsurface. It is the way each industry accomplishes that goal that is different. According to Thomas, mines are slower to develop and are “extremely slow to improve over time because they build fixed assets, with facilities equipped with bespoke systems.”

He said the fundamental expertise of the petroleum industry’s ability to drill and complete wells and then extract and process on the surface is an advantage.

“Mining doesn’t have the rapid development cycle of the oil and gas industry of drill, learn, and repeat,” he said. “Natural gas is so cheap to produce because we got really good at drilling and producing it over time because we tried many hundreds of thousands of times. You can’t do that with mines. Critical mineral dependency in this country must be tied to technology that can rapidly improve and get cheaper over time. That’s where we’ll get to the point of mineral abundance and not mineral dependency on foreign sources.”

Working together, the petroleum and mining industries can help drive innovation for a secure future. By combining geological insights with industrial expertise and artificial intelligence, important resources and the potential for a strong US supply chain can be realized.

For Further Reading

A Geo-Data Science Method for Assessing Unconventional Rare-Earth Element Resources in Sedimentary Systems by C.G. Creason, et al., Natural Resources Research.